Chinese Fiber Laser Cutter and Plasma Cutter Supplier

15 Yrs' Factory | No Middle Man | Support OEM

What We Can Offer

Jinan Light CNC Laser Equipment Co., Ltd. is a leading manufacturer in China, specializing in the design, R&D, production, and sales of CNC tube cutters, CNC plasma cutters, and CNC laser cutters. Have been running on metal cutting industry for over 15 years. We continue to offer high-quality, most suitable equipment according to clients’ exact working requirements. Through a long time’s development, LT machines are widely used in advertising, steel structures, bridges, engineering machinery, sheet metal processing, and metal tube processing. etc. Because of reliable quality and perfect service, LT has become a world-renowned CNC brand for beginners and professionals.

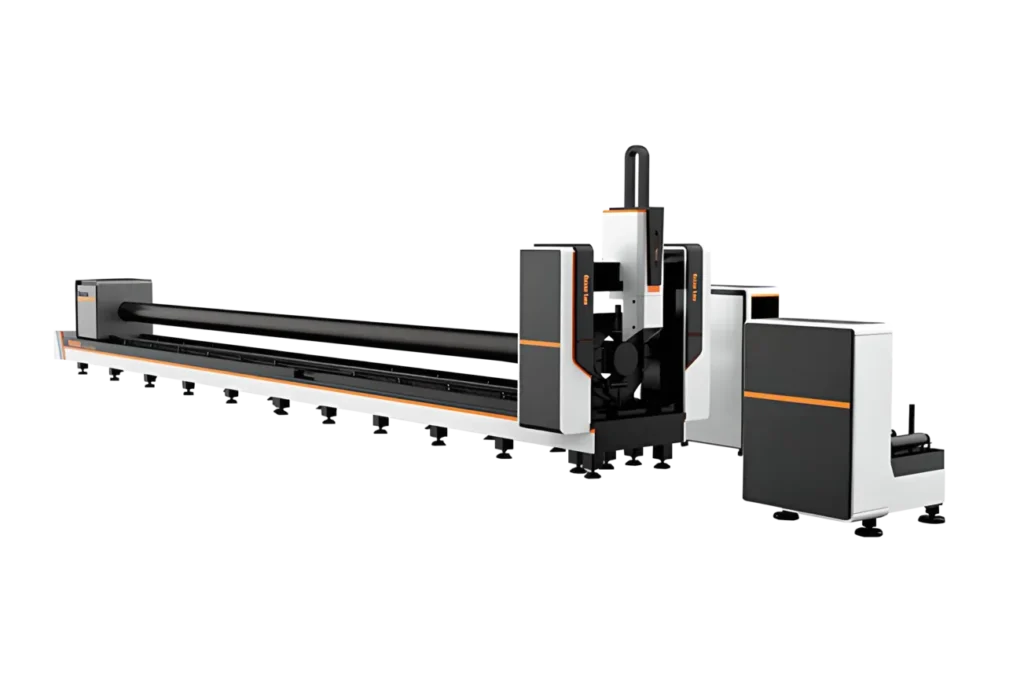

CNC Laser Cutter

We offer various styles of laser metal cutting machines, used for cutting different metal types materials in high precision

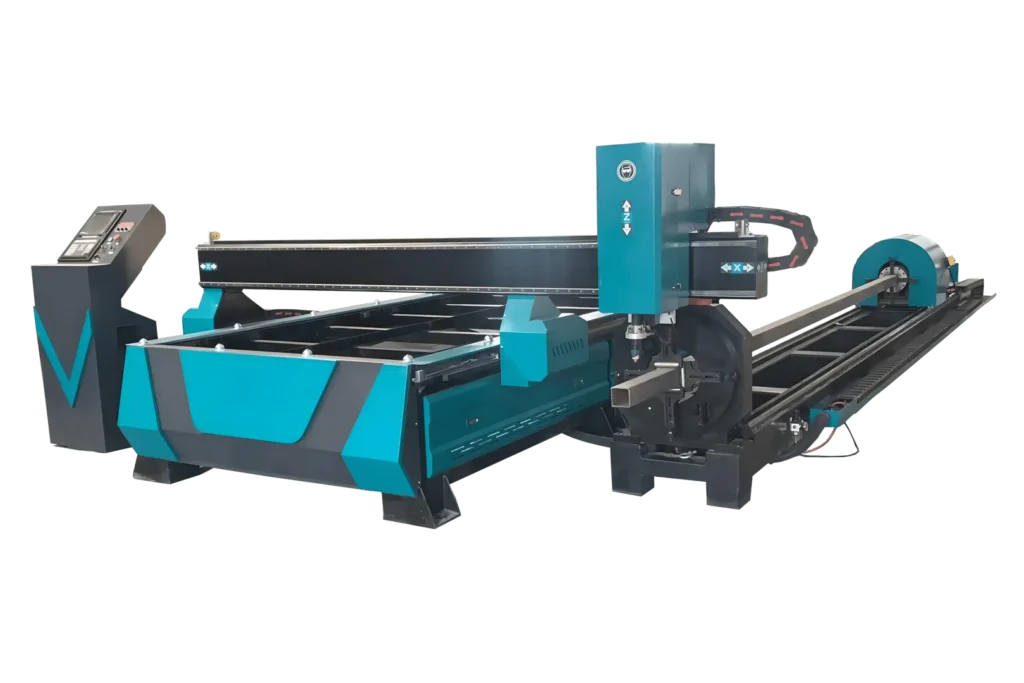

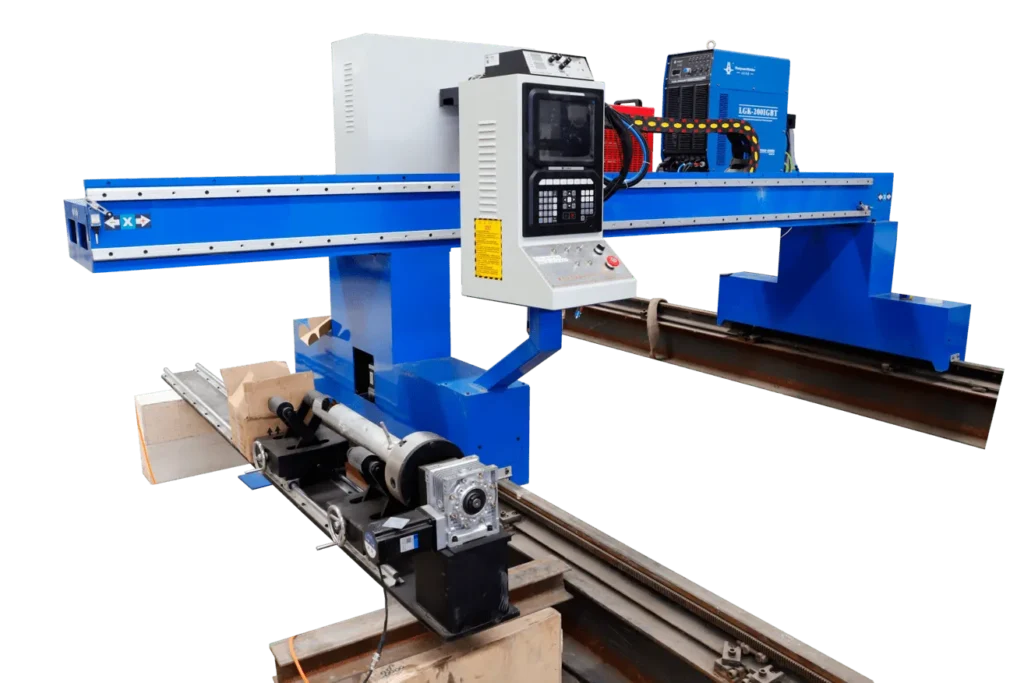

CNC Plasma Cutter

Our plasma cutting machines are designed for versatile metal cutting, suitable for thin and thicker materials processing.

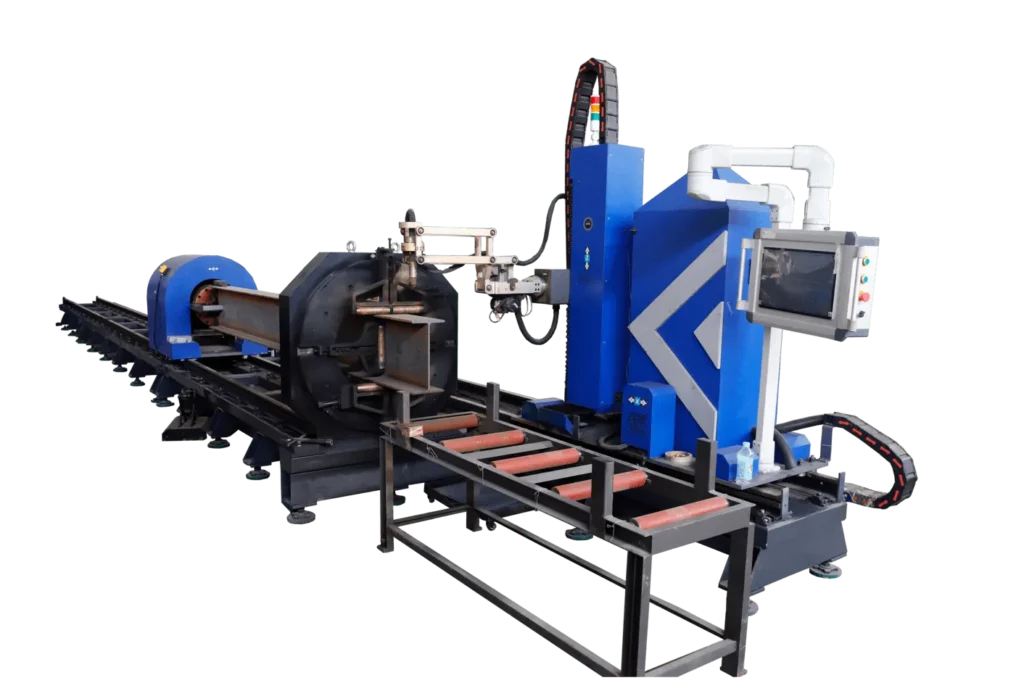

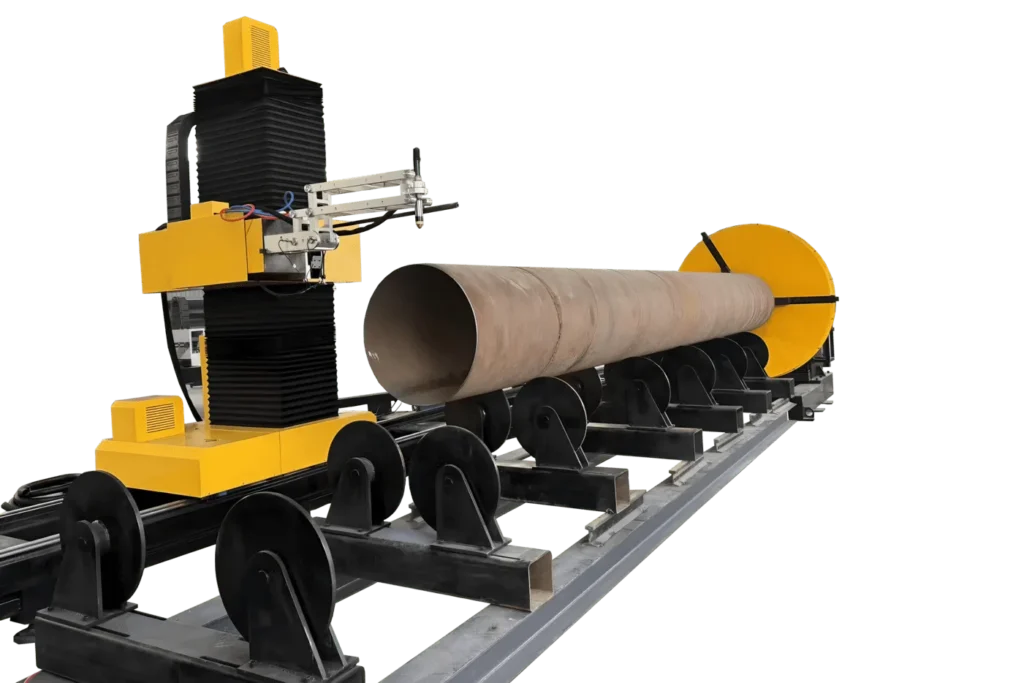

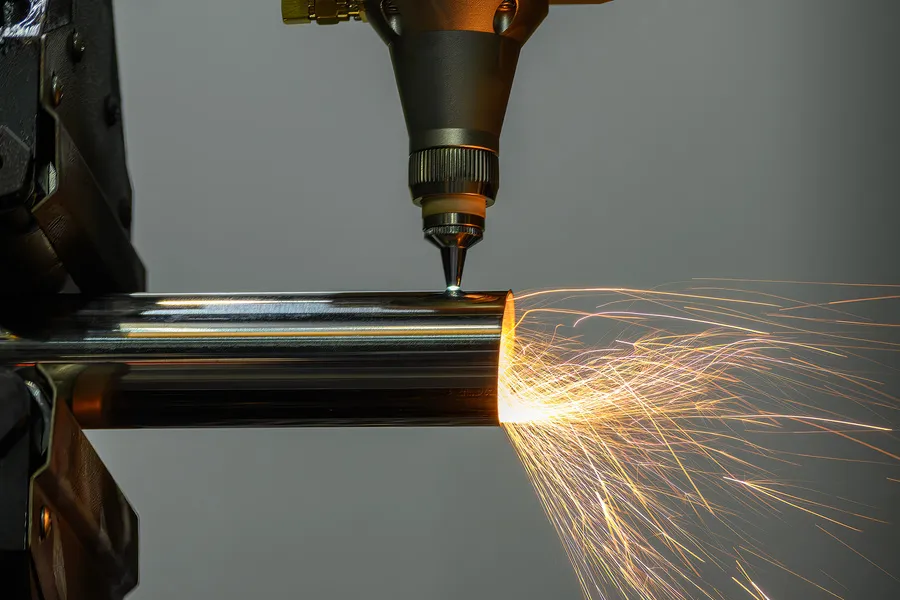

CNC Tube Cutter

CNC laser and plasma tube cutting machines, specialize in cutting round, square, H-beam and other metal tubes.

Applicable Industry

With superior cutting processes and results, our types of equipment, the metal laser cutter, metal plasma cutter, and CNC tube cutter, are widely used in many different industries, such as Advertising Industry, Automobile Manufacture Industry, Gym Equipment Industry, Machine Manufacturing Industry, Medical Equipment Industry, Sanitary Tools Industry, Sheet Metal Cutting Industry, Steel Structure Industry, Steel-Wood Furniture Industry, Tower Industry, and many other areas that required metal cutting solutions.

Tower Industry

Steel Structure Industry

Machine Manufacturing Industry

Sheet Metal Cutting Industry

Gym Equipment Industry

Steel-Wood Furniture Industry

Sanitary Tools Industry

Medical Equipment Industry

Automobile Manufacture Industry

Advertising Industry

Top Trading Subject

After 15 years of development, we have launched a variety of different types of CNC laser cutter, CNC plasma cutter and CNC tube cutter to meet the processing needs of different industries and materials. Whether you are a small business, home shop, school, education, teaching, training, hobbyists, commercial use, industrial manufacturing, you can find the right one among the many types of products. Below are some of our best sellers from our three product ranges, please take a look, or visit our different product category pages for more detailed product styles.

CNC Laser Cutter

Fiber Laser Cutting Machine is a CNC high-energy precision metal cutting equipment, can cut on all kinds of metal, including carbon steel, stainless steel, galvanized sheet, aluminum, copper, gold, silver, etc., and quickly process the designed graphic, and its cutting speed is controllable, generally 0.5m/min-100m/min. The cutting thickness is different according to the selected laser power, and the general thickness of the cutting is within 200mm, the optional laser is 1kw-60kw. The cutting thickness varies according to the selected laser power, generally the cutting thickness is within 200mm, and the optional laser is 1kw-60kw. sheet metal laser cutter,laser pipe cutting machine and many other types are also available to easily process various metal sheets, square pipes, round pipes, channels, H-beams, profiled steel, etc. Widely used in plate processing, machinery manufacturing, shipbuilding, aerospace, steel structure, steel wood furniture and other industries.

Affordable High-Precision 3015 Industrial Fiber Laser Cutting Machine

Industrial Fiber Laser Cutting Machine, a top-selling laser machine designed for flat precise metal cutting. 1kw-60kw are optional.

CNC Plasma Cutter

A CNC Plasma Cutting Machine is a computerized control equipment, designed for metal cutting. It uses a numerical controller to guide the plasma torch across a custom-sized cutting table (such as 4×4, 4×8, 5×10, or 6×12) to produce shapes and outlines according to specific requirements. The metal plasma cutter can cut nonferrous and ferrous metals, such as steel, iron, brass, copper, bronze, aluminum, titanium, and their alloys. It is widely used in automotive manufacturing, welding, industrial machinery, shipbuilding, aerospace, and commercial construction. etc. CNC plasma tables can easily cut sheet metals, tubes, rods, straps, and profiles, suitable for both beginners and professionals.

High-Performance CNC Plasma Cutter | Versatile Plasma Cutter

High-performance CNC plasma cutter, known for its simplicity, stability, and cost-effectiveness. Ideal for all metal cutting needs

CNC Tube Cutter

CNC Tube Cutting Machine is divided into fibre laser pipe cutting machine and plasma pipe cutting machine according to its cutting method. It is a special type of model which is specially designed to cut various types of pipes. According to the different types of pipes and cutting efficiency, there are also different models, like round pipe cutting machine, square and round pipe cutting machine, 5-axis fibre-optic pipe cutting machine, 8-axis plasma pipe cutting machine, as well as some high-end double chuck or triple chuck pipe cutting machine. It can process all kinds of round pipe, square pipe, H-beam, channel steel, I-beam, shaped steel and so on. Widely used in bridge construction, steel structure, engineering machinery, furniture, sports equipment and other industries.

High-Precision Fiber Laser Tube Cutting Machine | CNC Square and Round Tube Cutter

High-precision fiber laser tube cutting machine, perfect for cutting round and square tubes up to 7 meters long

We Can Offer All Models

Whether you’re an importer, brand owner, distributor, or agent looking to establish your own brand with unique machine designs, or an end-user needing custom features tailored to your specific work requirements, we’ve got you covered. Our R&D team is dedicated to creating perfect solution for you—whether it’s a high-performance machine, an affordable option, or the most powerful equipment available. Only offer your detailed requirement to us, we’ll work tirelessly to deliver exactly what you need.

Some Different OEM Subject

Meet Light CNC Laser

From the beginning, Light CNC Laser had a dream—to become the world’s most trusted supplier of metal cutting equipment. To achieve this, we have committed ourselves to excellence in every aspect . From initial consultations with clients, developing tailored solutions, ensuring product quality, providing after-sales support, and offering competitive pricing.etc, we strive to give our customers the best possible experience. Here, you can always find the highest quality products at the most reasonable prices. Whether you are just starting your business, looking to improve your factory’s efficiency, or are a professional brand owner or distributor, we have the perfect solution for you. We firmly believe that the sincerity and trust are the keys to creating a win-win cooperation. Thanks for the customers’ support in the world, has feed us to grow into what we are today.

Mission

Build the most Reliable CNC Machine Vendor in 30 Yrs

Vision

Continue to Making 30 Yrs+ Business With Every One Customer

Value

–Innovation

–Customer-Oriented

–Long-term cooperation

What We Have Achieved?

From our establishment, we have achieved significant milestones in the metal-cutting machine industry. Now,We have over 60 different models of metal laser cutters, cnc plasma cutters and cnc tube cutters, have exported to over 90 countries and regions all over the world. With over 1,400 global customers, we have produced and sold more than 2,600 units of equipment. Our machines are widely used in over 60 different fields, almost nearly every aspect of the metal processing industry.

How We Gurantee Machine Quality

Quality inspection is the most important part of the whole production process, and it is also a very important reason why the quality of products varies from different suppliers. Some suppliers only check the cut samples after the machine is ready, as long as the samples are OK, then the test is passed, but we are not in favour of this test standard. We feel that quality control should be carried out in every aspect of the production of the equipment, and only if the process is up to standard, the products produced can have stable performance and excellent working results. Therefore, we have developed our own unique quality inspection process, from the incoming material inspection, to the installation inspection, to the later finished product inspection and the final packaging inspection, we have developed a very detailed inspection content and high standards, no matter what the situation, only when the final test results fully comply with all of our testing standards, we will send the equipment to the customer. This is why we can continue to provide customers with high-quality products for more than ten years as one day, in our place, quality is always the cornerstone of development, is the life of our enterprise!

Incoming Quality Control

When machine’s parts arrive, our worker will check if all are well and reach our quality size standard.

Installation Inspection

Guarantee every part must be installed by our unique technician.

Technical Inspection

The technician will test and adjust to guarantee all the technical parameters are correct after installed well

Sample Testing

Cut some special samples to test the working effect.

24H Running Inspections

Machine will running 24 hours before packing. confirm all the parts work together well.

Frame Surface Inspection

Before packing, will check all the machine structures, frames, and confirm everywhere is well.

Packing Inspections

Confirm all the required machine parts be packed into the wooden boxes together.

Wooden Boex Inpsections

Check and confirm Wooden box is packed well. Logo and Mark are correct.

Business Partners

In order to ensure the stability and high quality of our products, we usually choose to cooperate with some famous accessory suppliers, and our rapid development could not have been achieved without their support, including motors from YASKAWA, fiber laser supply from IPG, MAX, Raycus, electric accessories from Schneider, laser head from Raytools, PRECITEC, control systems from BOCHU and Weihong, and so on.

What Does Customer Say Us?

Are you still unsure about purchasing CNC machines from Light CNC Laser? The best way to gain confidence is by reading authentic testimonials from our actual customers. We regularly conduct satisfaction surveys, inviting our customers to provide honest feedback on our products and services. As you’ll see in the following reviews, many users have shared their personal experiences with our machines. Light CNC Laser gathers insights from customers based on their experiences with the CNC machines they have purchased, as well as their opinions on the buying process, repair, and maintenance services. We are committed to providing high-quality products and exceptional services, which motivates us to continually innovate and grow.

David Harrison

The steel laser cutter I bought from Light CNC Laser works perfectly! What impressed me the most was their after-service. The team was always ready to help, providing quick and efficient support whenever I needed it. Great experience overall!

Edward Collins

The best plasma cutter I purchased from Light CNC Laser arrived in incredibly strong packing. I was really impressed with the care they took in securing everything. It arrived in perfect condition, ready to work straight out of the box!

James Anderson

I purchased an industrial laser cutter from Light CNC Laser, and I couldn’t be happier with the quality. The machine is incredibly reliable and precise, and it’s made a huge difference in my production line. Truly top-notch equipment!

George Robinson

I had some technical questions after receiving my best plasma cutter, and the online support from Light CNC Laser was fantastic. They patiently walked me through everything, ensuring I got the most out of my new machine. I’m very satisfied!

Thomas Bennett

Light CNC Laser’s steel laser cutter has exceeded my expectations. The working effect is amazing, with clean, precise cuts every time. It’s clear that this machine was built with high standards. I’m thrilled with the results!

Stephen Brooks

Light CNC Laser’s metal plasma cutter is a solid machine, but what really stands out is their maintenance support. They’ve been there whenever I needed them, keeping my machine running smoothly. Their commitment to customer service is exceptional!

Charles Miller

I was worried about timing, but Light CNC Laser delivered my steel laser cutter right on schedule. The punctual delivery allowed me to meet all my deadlines without any stress. Absolutely dependable service

Franklin Morgan

As a first-time buyer, I was nervous, but the professional suggestions from Light CNC Laser’s team made all the difference. They guided me through the process, helping me choose the perfect laser cutting machine manufacturer for my needs. I couldn’t be more grateful

Service Area

All Over The World

Time Operasional

08.00 AM - 06.00 PM

Location

Jinan, China