Fiber laser cutting technology has developed rapidly over the past decades, and fiber laser cutting machines are gradually replacing traditional cutting processes such as flame, plasma, and mechanical cutting. Compared with plasma or flame cutting, fiber laser cutting offers higher precision, higher efficiency, flexible manufacturing, and environmental friendliness. Its high electro-optical conversion efficiency and finer beam diameter enable cutting tolerances down to 0.05 mm, and cutting speeds multiple times faster than traditional equipment. The non-contact process produces minimal additional consumables and pollution, reducing both energy consumption and waste. These advantages make fiber laser cutting machines the core tool for production innovation across many industries.

Below, we introduce, in sequence, 16 typical application sectors, including but not limited to sheet processing, tube processing, automotive manufacturing, aerospace, construction machinery, furniture, signage, bridge building, medical devices, environmental equipment, home appliances, oil & gas piping, cookware, sporting goods, new energy, and shipbuilding. Each sector section covers:

- The specific metal processing needs of the industry

- Typical ways in which laser cutting is applied

- Technical advantages compared with traditional processes

- Real or simulated customer cases or scenarios

Finally, we summarize the global market potential of fiber laser cutting technology, emphasizing its importance in the trends of smart manufacturing and green manufacturing. Where possible, we include a table showing the key demand focus for different application areas.

1. Sheet Metal Processing

sheet metal processing Industry

Industry Needs:

Sheet metal processors need to flexibly cut metal plates of various thicknesses and materials to produce parts in different shapes. They handle a wide variety of job types and batch sizes, demanding both high-precision complex cutting and high-speed throughput to shorten delivery cycles.

Laser Application:

Fiber laser cutting machines have become the standard in sheet metal processing. They can import CAD profiles and cut any contour in one step, from thin stainless-steel decorative parts to thick structural plates. Traditional shearing or punching requires dies, which are costly and inflexible, whereas lasers require no molds, solving these issues.

Technical Advantages:

- Smaller heat-affected zone, narrow and smooth kerf—often no secondary processing required

- No molds needed for complex shapes, accelerating new product development

- Reduced material waste and labor for finishing

Application Case:

A sheet metal factory installed a fiber laser cutter and expanded its offerings from simple rectangular pieces to complex curved panels. For example, a custom electrical enclosure sample that previously took weeks to produce via die making can now be cut by laser and delivered the same day. The cut edges are smooth and dimensionally accurate, allowing direct bending and assembly, significantly shortening product-to-market time.

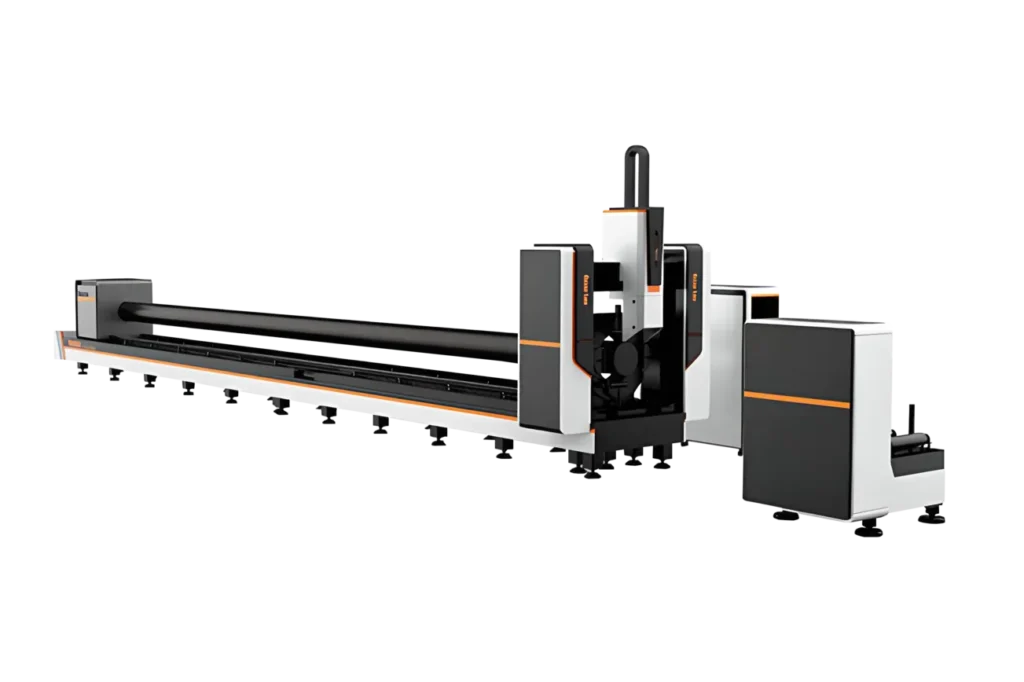

2. Tube Processing

tube pipe processing industry

Industry Needs:

Tube processing is ubiquitous across manufacturing, covering structural frames, piping, steel furniture, etc. Traditional tube cutting uses sawing followed by drilling or milling, with many steps and limited capability for complex shapes. The industry needs a machine that can quickly and accurately cut, drill, and slot tubing of various cross-sections.

Laser Application:

Laser tube cutting machines are specially designed for this task. Equipped with rotating clamping and CNC laser heads, they can cut 360° arbitrary geometries on tubes. Whether straight cuts, angled cuts, holes, slots, or bevels, one machine completes all in one pass. A single laser tube cutter can replace multiple saws, drill presses, and mills, achieving from cut-to-hole in one setup.

Technical Advantages:

- ± 0.05 mm precision, burr-free kerf—often no finishing needed

- Non-contact heat cutting minimizes deformation, ideal for thin-walled tubes and high-precision parts

- Automated loading, alignment, and unloading enables high-efficiency batch processing

Application Case:

In automotive and bicycle manufacturing, large volumes of tubular frame parts are cut with high-precision bevels and bolt holes in one pass. Welders report near-100% first-pass success and 30% assembly-time savings due to precise fish-mouth bevels and hole placement.

3. Automotive Manufacturing

Automobile Industry

Industry Needs:

Automotive manufacturing involves thousands of metal parts, from body panels to exhaust tubing. Traditional large-volume production relies on stamping dies, which are costly and inflexible, especially during model changes or prototype phases. Parts require both high-speed output and tight tolerances to meet assembly line standards.

Laser Application:

Fiber lasers are widely used for both 2D blanking and 3D trimming.

- 2D blanking: Cutting prototype panel shapes or small-lot body panels directly from sheet without dies.

- 3D trimming: Robot-mounted laser heads remove burrs and trim stamped parts (door inner panels, exhaust pipes) with ± 0.1 mm accuracy, crucial for fit and weld quality.

Technical Advantages:

- Smooth, vertical kerf without burrs, reducing pre-weld finishing

- Easy integration with robotic systems for automated, high-precision trimming

- ± 0.1 mm repeatability ensures consistent assembly

Application Case:

A manufacturer uses 3D laser trimming for door panels during R&D. A test batch of door blanks is laser-cut in minutes, meeting tolerances without die changes, accelerating prototype cycles by weeks.

4. Aerospace

Aerospace industry

Industry Needs:

Aerospace demands some of the strictest requirements for metal parts—both sheet and tubular—made from titanium, aluminum, and stainless steel. Parts must meet tolerances of ± 0.05 mm or better to ensure structural integrity, with minimal thermal distortion and high repeatability.

Laser Application:

- Gantry-mounted lasers cut thick aluminum frame ribs and panels with ± 0.05 mm precision.

- Five-axis lasers machine turbine blade cooling holes and disk contours in one operation, preserving surface integrity and avoiding microcracks.

- Non-contact processing avoids subsurface damage and material work hardening.

Technical Advantages:

- Ultra-high precision and kerf quality—no secondary machining required

- Compatible with difficult alloys (titanium, high-strength aluminum), avoiding tool wear

- Flexible, die-free machining ideal for low-volume, high-customization aerospace programs

Application Case:

A satellite manufacturer laser-cuts large aluminum panels and internal ribs. Each part exits ready to assemble, with mounting holes and lightening cut-outs produced in a single pass. Assembly time shrank dramatically, eliminating manual fitting and rework.

5. Construction Machinery

Construction Machinery

Industry Needs:

Construction machinery (excavators, cranes, mining equipment) uses large, thick structural plates and beams. Traditional plasma or flame cutting handles thickness but requires drilling and milling for holes, with multiple setups. Rapid model updates demand flexible, integrated processes.

Laser Application:

High-power fiber lasers now cut plates from 20 mm to 40 mm thick with square edges and precision holes in one cycle, simultaneously performing cut-to-hole and chamfering. Marking functions can etch assembly lines and hole centers, eliminating manual layout.

Technical Advantages:

- Integrated multi-feature machining: cut, drill, chamfer in one go

- Improved hole accuracy and repeatability

- Reduced distortion compared to plasma, preserving weld fit-up

Application Case:

A manufacturer of rock crusher frames cuts a 30 mm thick chassis beam with mounting holes and bevels in one pass. Assembly time for the boom dropped by 40%, and hole placement deviation averaged below 0.2 mm for hundreds of holes.

6. Furniture Manufacturing

Furniture Manufacturing Industry

Industry Needs:

Metal furniture (cabinets, frames, decorative screens) demands both structural parts and decorative patterns. Modern designs require intricate cut-outs and tight tolerances, with batch consistency and bespoke options.

Laser Application:

- Decorative screen panels with complex patterns cut on sheet metal

- Tube frames profiled without burring

- Tight nesting for minimal material waste

Technical Advantages:

- Intricate designs at no extra cost compared to simple shapes

- Burr-free edges eliminate secondary finishing

- Flexible small-batch to mass-production changeover

Application Case:

An interior design firm laser-cuts steel room dividers with complex geometric patterns. What once took water-jet or manual labor now delivers same-day with pristine edges, expanding their product offerings.

7. Signage & Advertising

Signage Advertising Industry

Industry Needs:

Outdoor signs, 3D channel letters, lightboxes, and art installations require fast, accurate cutting of thin metals with detailed fonts and graphics. Lead times are short and batch sizes are often small.

Laser Application:

Fiber lasers read vector graphics and cut complex shapes in minutes, regardless of design complexity. The resulting parts are burr-free and move directly to finishing with minimal handling.

Technical Advantages:

- Rapid turnaround (“order today, deliver tomorrow”)

- Fine detail cut without distortion or burning

- Wide material compatibility (stainless, aluminum, copper)

Application Case:

A sign shop produces stainless-steel channel letters for a mall interior in half a day. Laser-cut edges are mirror smooth, requiring no further finishing before LED mounting.

8. Bridge & Structural Steel

Bridge Structural Steel Industry

Industry Needs:

Bridge and building steel structures use thick plates and sections for web plates, stiffeners, gusset plates, etc. Precision bolt holes and beveled edges are critical for field fit-up. Traditional flame/plasma lacks the precision and creates slag.

Laser Application:

Large gantry fiber lasers cut multi-meter plates with clean vertical cuts, minimal slag, and accurate holes ready for field bolting—eliminating on-site grind work.

Technical Advantages:

- High accuracy and surface quality—no secondary grinding

- Faster throughput than flame/plasma, boosting output

- Reduced material waste via tight nesting, lowering overall cost

Application Case:

A bridge fabricator laser-cuts 20 mm gusset plates with slots and bolt patterns. On-site erection saw perfect bolt alignment, eliminating field rework and speeding construction.

9. Medical Devices

Medical Devices Industry

Industry Needs:

Surgical tools, implants, stents, and micro-instruments require burr-free microfeatures in stainless steel or titanium. Parts must remain pristine for biocompatibility.

Laser Application:

- Non-contact micro-cutting down to a few hundred microns

- No coolant or lubricants, preserving medical cleanliness

- Rapid small-batch production of high-mix parts

Technical Advantages:

- Ultrahigh precision for fine features and slots

- Minimal heat-affected zone avoids microcracks

- Clean surfaces ready for sterilization

Application Case:

A maker of cardiovascular stents laser-cuts mesh patterns from thin tubes, ensuring uniform micro-slits. Each batch meets strict dimensional and biocompatibility criteria.

10. Environmental Equipment

Environmental Equipment industry

Industry Needs:

Air pollution control, water treatment, and waste management equipment involve large housings, internals, piping, and frames. Customized, modular parts with varied thicknesses are common.

Laser Application:

High-power lasers cut large panels and internal support plates in one pass, etch identification marks, and ensure tight seals for pollutant containment—key for environmental reliability.

Technical Advantages:

- Large-format, high-precision cutting for leak-free assemblies

- Reduced scrap and tight tolerances lower operating costs

- Clean process with minimal emissions

Application Case:

An industrial dust collector OEM laser-cuts 10 mm shell panels with integrated stiffeners. Panels nest efficiently, fit precisely, and minimize sealant use, boosting airflow performance.

11. Home Appliances

Home Appliances industry

Industry Needs:

Refrigerators, washing machines, air conditioners, and kitchen appliances require high-volume sheet metal enclosures, brackets, vent holes, and decorative trims. Rapid prototyping and flexible production for new models are essential.

Laser Application:

- Prototype panels cut on-demand, avoiding die costs and delays

- Flexible small-batch or limited-run production of special models

- Multi-head lasers handle high-volume runs comparably to stamping with no die changes

Technical Advantages:

- Fast turnaround for R&D prototypes and test runs

- Consistent part quality without tool wear

- Easy product model changeover

Application Case:

A kitchen appliance maker shifted small-batch cover panels to laser cutting. New model panels that once required molds now arrive same-day, reducing mold inventory and accelerating market entry.

12. Oil & Gas Piping

Gas Oil pipe industry

Industry Needs:

Thick-wall piping for exploration, drilling, and transport; T-connections; bevel end preps; and branch holes require high precision to ensure leak-free, pressure-tight assemblies. Traditional flame-cutting is imprecise and leaves slag.

Laser Application:

Five-axis pipe lasers cut end preps, branch openings, and angled joints in one cycle, producing burr-free holes and accurate bevels with minimal heat-affected zones.

Technical Advantages:

- ± 0.5 mm accuracy on thick-wall tubes

- Clean internal surfaces without burrs

- Integrated multi-feature processing reduces setups

Application Case:

A pipeline fabricator laser-cuts large-diameter spool pieces with perfect fish-mouth cuts. Welders report a 25% increase in first-pass weld speed due to snug fits.

13. Cookware & Kitchenware

Cookware Kitchenware Industry

Industry Needs:

Manufacture of stainless-steel sinks, stove cutouts, pans, knives, and kitchen equipment requires burr-free cuts on thin gauge. Decorative patterns or logos add complexity.

Laser Application:

- Cuts 1–3 mm stainless steel cleanly, with minimal kerf

- Decorative perforations and edge profiling in one pass

- Optimal nesting reduces waste of costly materials

Technical Advantages:

- High speed for large volumes of flatware blanks

- Consistent dimensions for lids, pans, and sink cutouts

- Customization and low-volume orders are economical

Application Case:

A custom kitchen fabricator laser-cuts sink openings and designer bowls from sheet. Intricate patterns once requiring water-jet now ship ready to polish, elevating product quality.

14. Sporting Goods

Sporting goods industry

Industry Needs:

Fitness equipment frames, gym rigs, cycling frames, and stadium railings use both tube and sheet metal, demanding precision slots and holes for adjustment mechanisms. High mix of standard and custom products.

Laser Application:

- Tube lasers cut length, angle, slots, and holes in one setup

- High-throughput for fitness OEMs during peak demand

- Smooth edges and precise hole placement

Technical Advantages:

- Reduced manual setup time, increased capacity

- ± 0.05 mm positioning ensures safe, reliable equipment

- Rapid changeover for custom orders

Application Case:

A fitness equipment manufacturer laser-cuts treadmill and exercise bike frames. Frame assembly time is cut by over half, and all holes align perfectly for smooth installation.

15. New Energy

New Energy Industry

Industry Needs:

Components for electric vehicles, battery racks, solar mounts, and wind turbine parts require high-strength alloys, lightweight materials, and rapid iteration to support evolving designs.

Laser Application:

- 3D five-axis lasers trim hot-stamped high-strength steel EV body parts with ± 0.1 mm accuracy

- Fiber lasers cut battery tray panels and PV mounting frames in large formats

- Automated lines integrate robots and AGVs for lights-out production

Technical Advantages:

- Processes lightweight alloys and composites

- Minimal thermal impact preserves material properties

- Highly automated, flexible production supports rapid design cycles and multi-variant manufacturing

Application Case:

An EV OEM uses 5-axis laser trimming for hot-stamped steel chassis components—parts exit cut and drilled in one operation, seamlessly meeting fit-up specs and reducing scrap.

16. Shipbuilding

Shipbuilding Indsutry

Industry Needs:

Hull plates, bulkheads, stiffeners, and piping in ship blocks require cutting of very large plates (up to 20–30 mm thick). Precise bevels and minimal deformation are critical for modular block assembly.

Laser Application:

- Hybrid laser/plasma gantries cut thin and medium plates with minimal dross and precise bevels for welding preparation

- Gantry widths exceed 10 m to handle massive panels

- Laser-prepared bevels eliminate extensive grinding before welding

Technical Advantages:

- High-quality kerf reduces plate edge preparation time

- Low distortion preserves flatness for modular assembly

- Cleaner cutting process improves shop environment and safety

Application Case:

A shipyard adopted a hybrid system: plates under 20 mm cut by fiber laser, thicker plates by plasma. Laser-cut panels snapped together with no rework, slashing block fit-up time and boosting weld quality.

Industry Demand Overview

| Application Area | Key Laser Requirements |

|---|---|

| Sheet Processing | Wide material/thickness range; high precision & speed; flexible nesting |

| Tube Processing | Arbitrary section cutting & holes; high throughput; minimal burrs |

| Automotive | High-volume, automated line integration; ± 0.1 mm tolerances |

| Aerospace | Ultra-tight tolerances; 5-axis capability; low thermal impact |

| Heavy Equipment | Thick-plate cutting up to 40 mm; multi-feature integration |

| Furniture | Decorative patterns; smooth edges; batch & bespoke flexibility |

| Signage & Advertising | Fast, detailed cutouts; no mold costs; swift design changes |

| Bridge & Structural | Large gantries; precise bolt-hole cutting; improved fit-up |

| Medical Devices | Burr-free micro-features; biocompatible alloys; small batches |

| Environmental Equipment | Large panel cutting; custom module work; improved sealing |

| Appliances | Rapid prototyping; flexible production; moldless switching |

| Oil & Gas Piping | End prep cuts; branch openings; burr-free bores |

| Cookware & Kitchenware | Thin-gauge stainless; safe surfaces; decorative cutouts |

| Sporting Goods | Tube frames & slots; batch + custom; assembly-ready parts |

| New Energy | Lightweight alloys; automated high-volume; large formats |

| Shipbuilding | Mega-plate cutting; precise bevels; modular block assembly |

Conclusion

Fiber laser cutting technology is now active in every corner of global manufacturing—from basic sheet and tube processing to the most demanding sectors like aerospace and new energy. Across all 16 industries, companies have realized significant gains in productivity, cost reduction, design flexibility, and product quality. Under the dual trends of Industry 4.0 and green manufacturing, fiber laser cutting machines have become core tools driving industrial upgrades. According to market reports, global demand for fiber laser cutting equipment continues to grow, with manufacturers worldwide investing in this technology. We can foresee that fiber laser cutting will become a standard capability in modern manufacturing, offering a faster, more precise, and eco-friendly industrial future. Organizations that adopt and master fiber laser cutting will gain a clear competitive advantage, co-creating a bright, intelligent, and sustainable manufacturing landscape.

References

- Oree Laser – Which industries can fiber laser cutting machine be used in?

- Baison – Top Laser Cutting Applications in Various Industries

- Han’s Laser – Inventory of fiber laser cutting machine applications in the most industries

- TEYU Chiller – Do you know how many industries fiber laser cutting machines are used in?

- Senfeng Laser – Application of Fiber Laser Technology in Ships

- HGTECH – Why Does The Steel Structure Industry Need Laser Cutting Machines?

- TubeForm Solutions – Why Use a Laser Pipe Cutter?

- KNS Metals – 5 Industry Applications of Tube Laser Cutting

- MM Modern Manufacturing – 激光切割机在新能源行业的应用