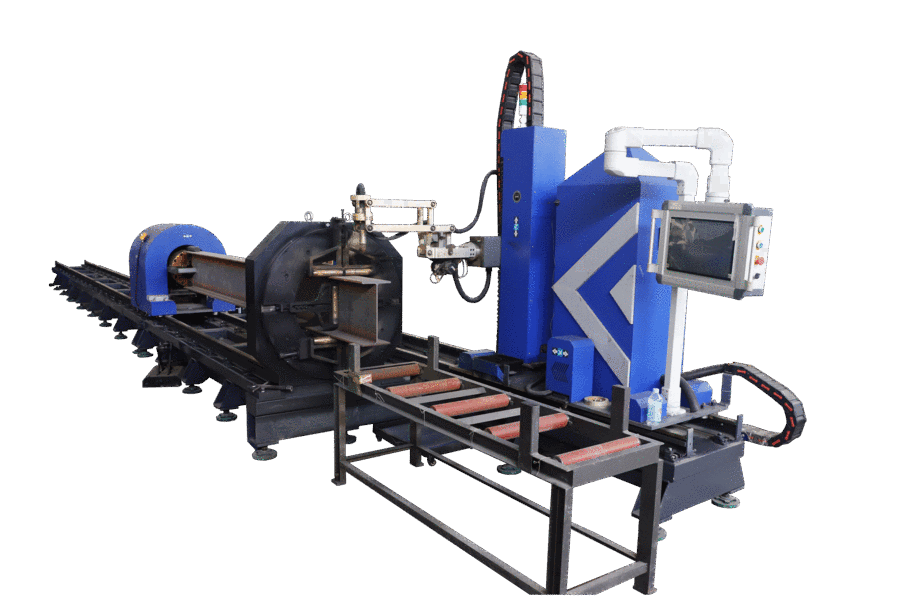

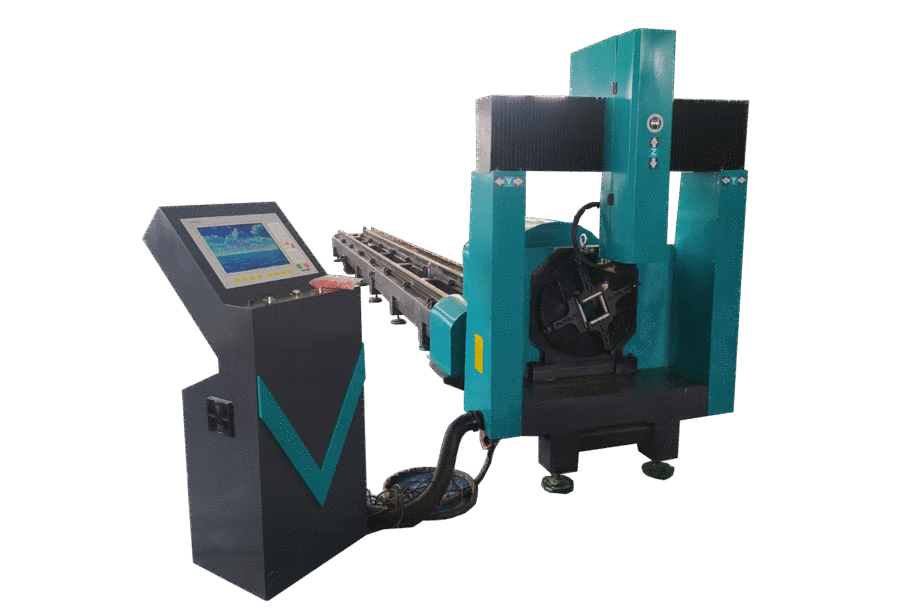

5-Axis CNC Plasma Tube Profiling Machine | Versatile Plasma Cutter for Pipes

Discover our 5-axis CNC plasma tube profiling machine, designed for cutting round, square, H-beam, and custom pipes which finished products over 3 meters long. Max process materials’ diameters up to 800mm, 12000mm length,offering unmatched precision and versatility.

Heavy-Duty 5-Axis Plasma Cutter for Round, Square, and Custom Pipes

Model: LT24120-PT2

Working area: Pipe-φ245mm, Tube side-max 200mm, 12000mm length,(320mm, 420mm,500mm, 600mm, 800mm diameter as options)

Support Plasma Power: LGK120A/160A/200A

Price Range: $290 00 – $850 00

Warranty time: 1 year for the whole machine

Delivery time: 15 workdays

Technical Support Time: Free Lifetime for All Clients

Machine Videos

Technical Parameter

| Model | LT24120-PT2 |

|---|---|

| Plasma power | LGK120A/160A/200A |

| Max process tube diameter size | Pipe-φ245mm, Tube side-max 200mm, 12000mm length,(320mm, 420mm,500mm, 600mm, 800mm diameter as options) |

| Type of cutting material | Round pipe, square pipe, angle steel, slot steel.etc |

| Plasma-cutting pipe wall thickness | Max 20mm batch below 15mm |

| Cut material length | 12000mm |

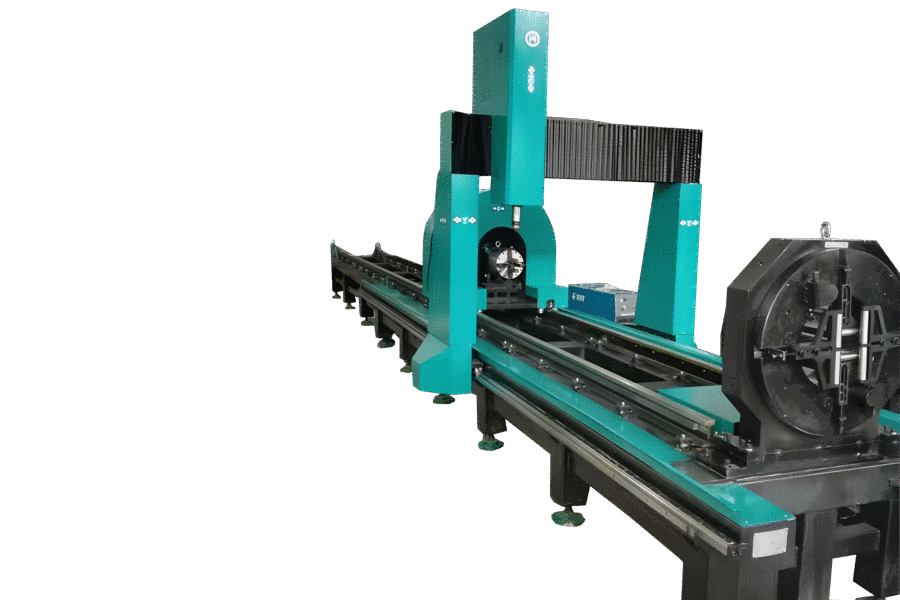

| Diameter section | 245x245mm(320*320mm,420*420mm,500*500mm,600*600mm,800*800mm as options) |

| Cutting accuracy | 0.2mm |

| The fastest plasma cutting speed | 25 m / min |

| repeated positioning accuracy | ± 0.03mm |

| bus positioning accuracy | ± 0.03mm |

| oblique port positioning accuracy | ± 0.05mm |

| Electrical control cabinet | ZLQ-XGEC |

| Chuck Styles | 245mm is air-drive Chuck, other bigger size are mannual-drive Chucks |

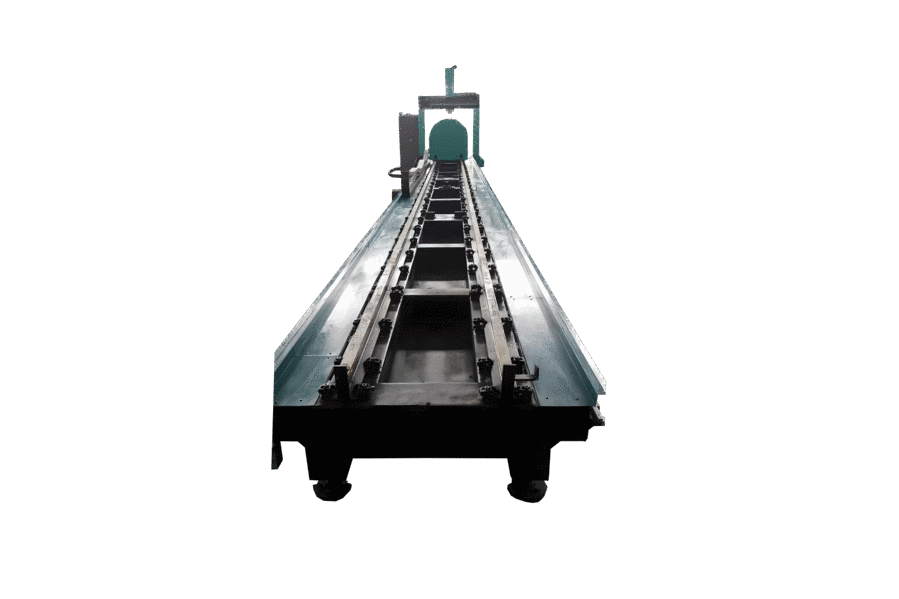

| Bed body composition | 8m |

| weight of equipment | 3500KG |

Machine Features

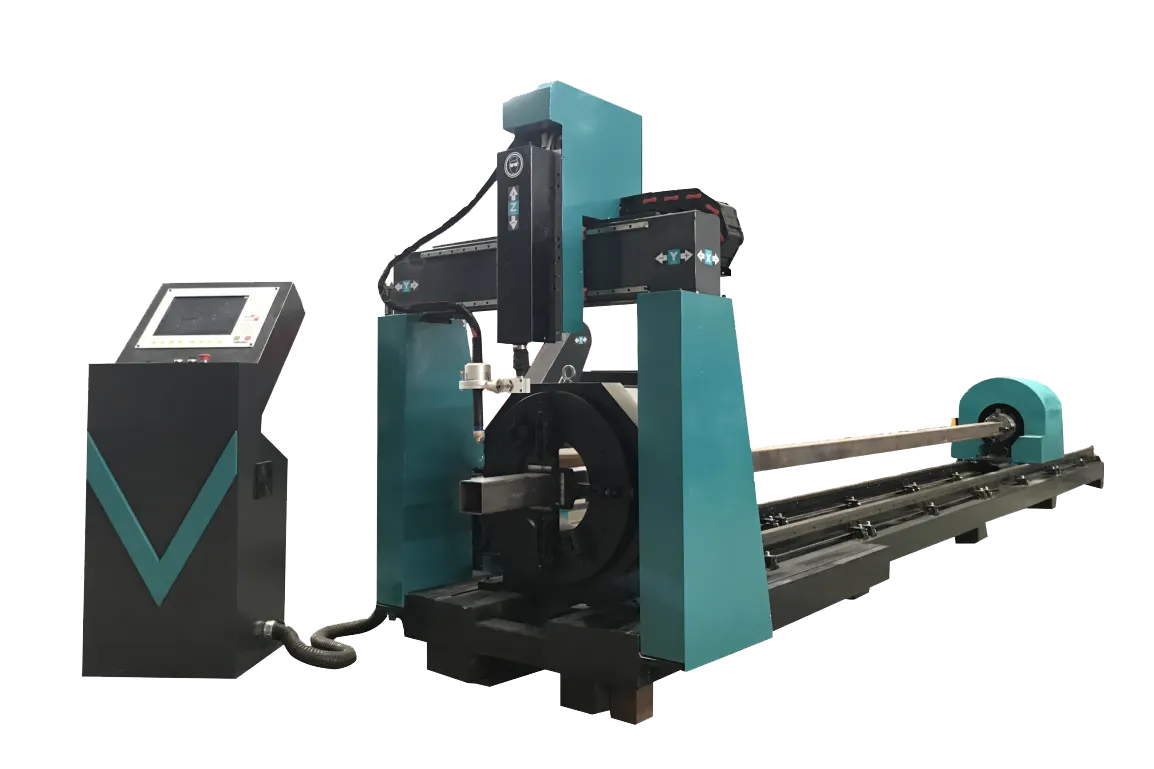

Unique Advantages: Adopt to use Heavy-tube welding machine frame, support strong stability for cutting various heavy tube materials. Beam-moving design can cut the 3m length big size materials.

PC Controller: Intelligent control system, let whole operation become more easily and high efficiency.

Plasma Head: P80 professional plasma head, equipped with big Z axis height system, suitable for cutting big diameter tube materials.

Plasma Power Supply: Support LGK120A, 160A, 200A and 300A plasma source, will recommend the suitable model according to materials thickness and working efficiency.

| Different Powers' Plasma Cutting Supply Technical Parameter | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chinese LGK Plasma Power Supply | ||||||||||||||||

| Power | LGK-63IGBT | LGK-120IGBT | LGK-160IGBT | LGK-200IGBT | LGK-300HD | LGK-400HD | ||||||||||

| Working Effect | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | ||||

| Carbon steel | 25mm | 15mm | 45mm | 25mm | 60mm | 30mm | 70mm | 35mm | 100mm | 0.3-50mm | 120mm | 1-60mm | ||||

| Stainless steel | 20mm | 12mm | 36mm | 20mm | 48mm | 24mm | 56mm | 28mm | 80mm | 40mm | 95mm | 48mm | ||||

| Aluminum | 15mm | 9mm | 27mm | 15mm | 36mm | 18mm | 42mm | 21mm | 60mm | 30mm | 72mm | 72mm | ||||

| Brass | 15mm | 9mm | 27mm | 15mm | 36mm | 18mm | 42mm | 21mm | 60mm | 30mm | 72mm | 72mm | ||||

| American Hypertherm Plasma Power Supply | ||||||||||||||||

| Power | Powermax45 SYNC | Powermax65 SYNC | Powermax85 SYNC | Powermax105 SYNC | Powermax125 | MAXPRO200 | XPR300 | HPR400XD | ||||||||

| Working Effect | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut |

| Carbon Steel | 29mm | 16mm | 32mm | 20mm | 38mm | 20mm | 50mm | 22mm | 57mm | 30mm | 75mm | 35mm | 80mm | 50mm | 80mm | 50mm |

| Stainless Steel | 22mm | 12mm | 25mm | 15mm | 30mm | 16mm | 40mm | 18mm | 45mm | 24mm | 60mm | 25mm | 75mm | 50mm | 80mm | 45mm |

| Aluminum | 16mm | 10mm | 20mm | 12mm | 22mm | 12mm | 30mm | 15mm | 35mm | 18mm | 45mm | 25mm | 50mm | 25mm | 80mm | 45mm |

| Brass | 16mm | 10mm | 20mm | 12mm | 22mm | 12mm | 30mm | 15mm | 35mm | 18mm | 45mm | 25mm | 50mm | 25mm | 80mm | 45mm |

| Attention:Above technical parameter comes from LGK and Hypertherm website, Contains exaggerated elements, cannot take as the rule of adopting suitable power,please contact us ask for the exact suitable schemes |

||||||||||||||||

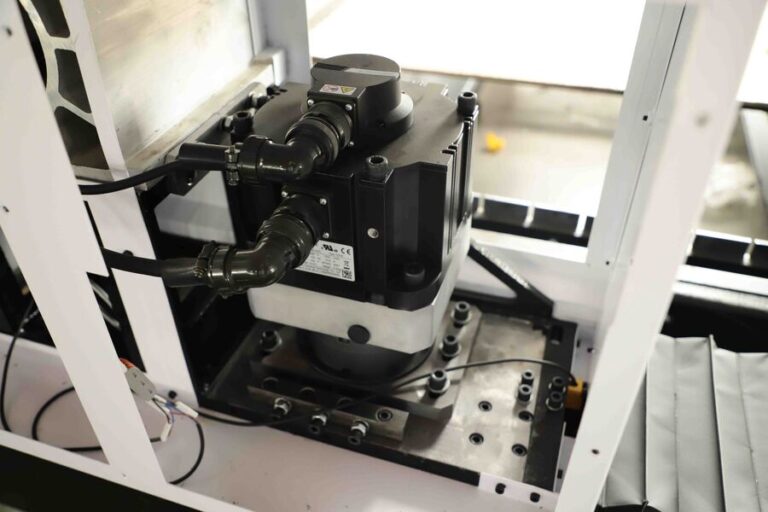

Driving System: Big power servo motor with reducer can not only offer the high power to drive machine working on fast speed, also offer the highest working precisions.

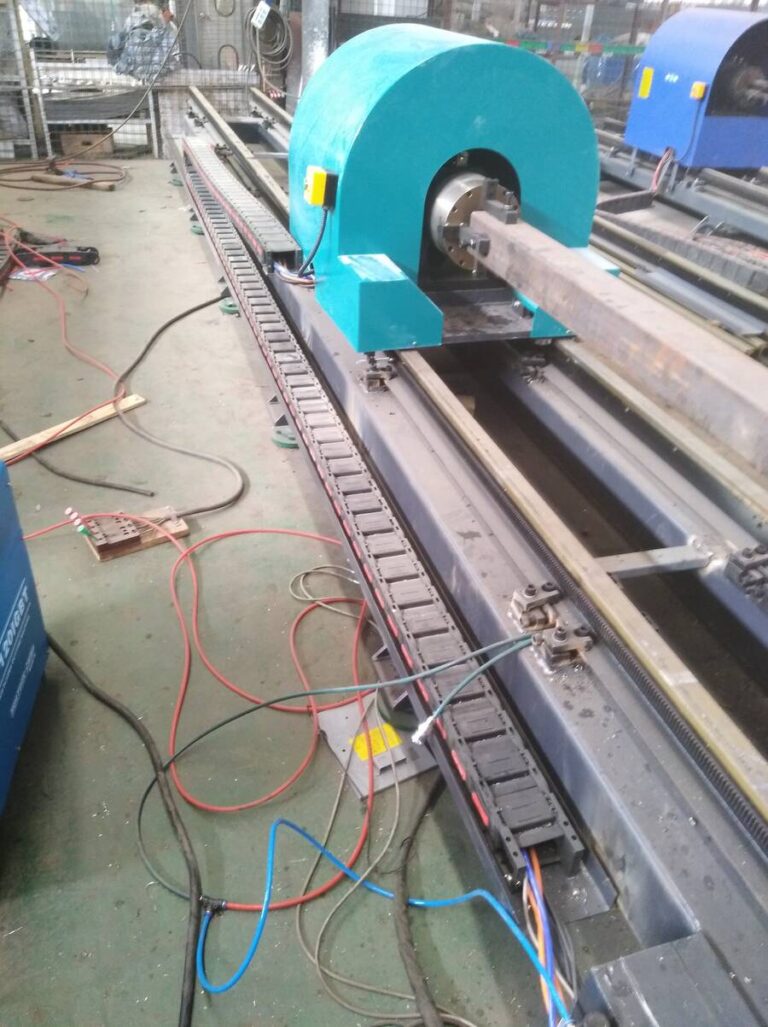

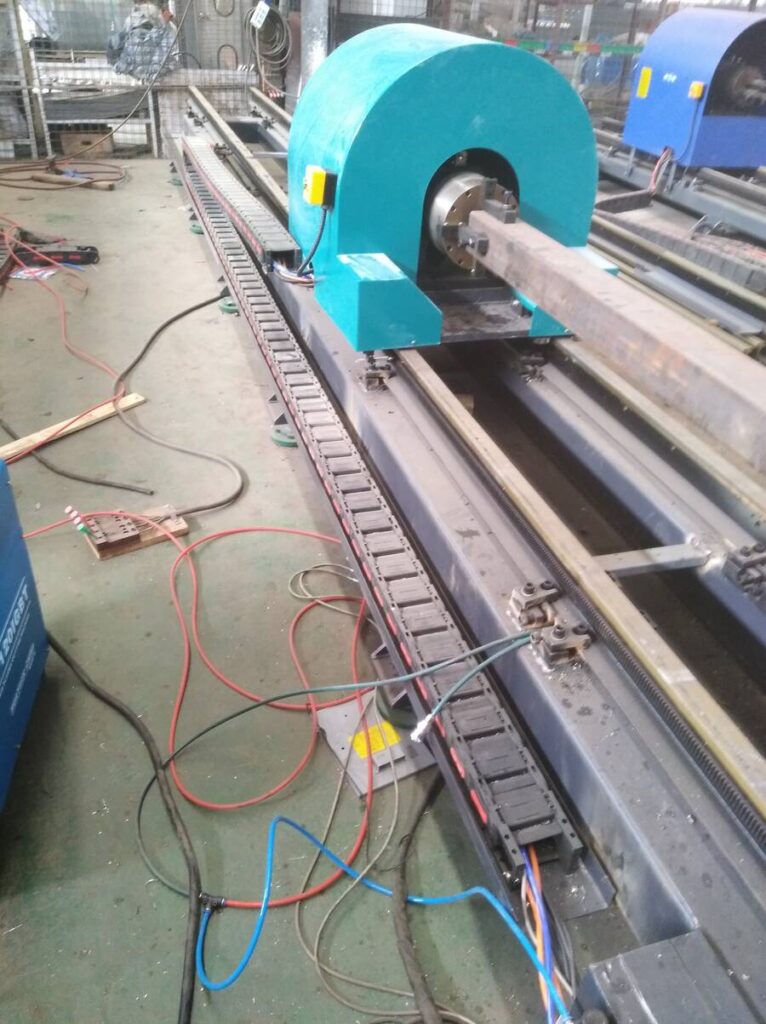

Double Chuck System: Mnaual driven double chuck system, specialize in chuck over 320mm diameter big tube materials.

Transmission System: Hihg precision grinding rack add imported YYC perfect guild offer best working precision and longer service life, help machine process complex products on best accurancy.

Heavy welding Frame: Adopt to use sheet-tube whole welding structures, can keep perfect stability when high working.

Some Related Machine Pictures

Applicable Industry

With superior cutting processes and results, our types of equipment, Plasma Tube Cutting Machine, is widely used in many different industries, such as the Advertising Industry, Automobile Manufacture Industry, Gym Equipment Industry, Machine Manufacturing Industry, Medical Equipment Industry, Sanitary Tools Industry, Sheet Metal Cutting Industry, Steel Structure Industry, Steel-Wood Furniture Industry, Tower Industry, and many other areas that required metal cutting solutions.

Aerospace Industry

New Energy Industry

Machine Manufacturing Industry

Tube Cutting Industry

Gym Equipment Industry

Steel-Wood Furniture Industry

Sanitary Tools Industry

Medical Equipment Industry

Automobile Manufacture Industry

Handicraft Industry