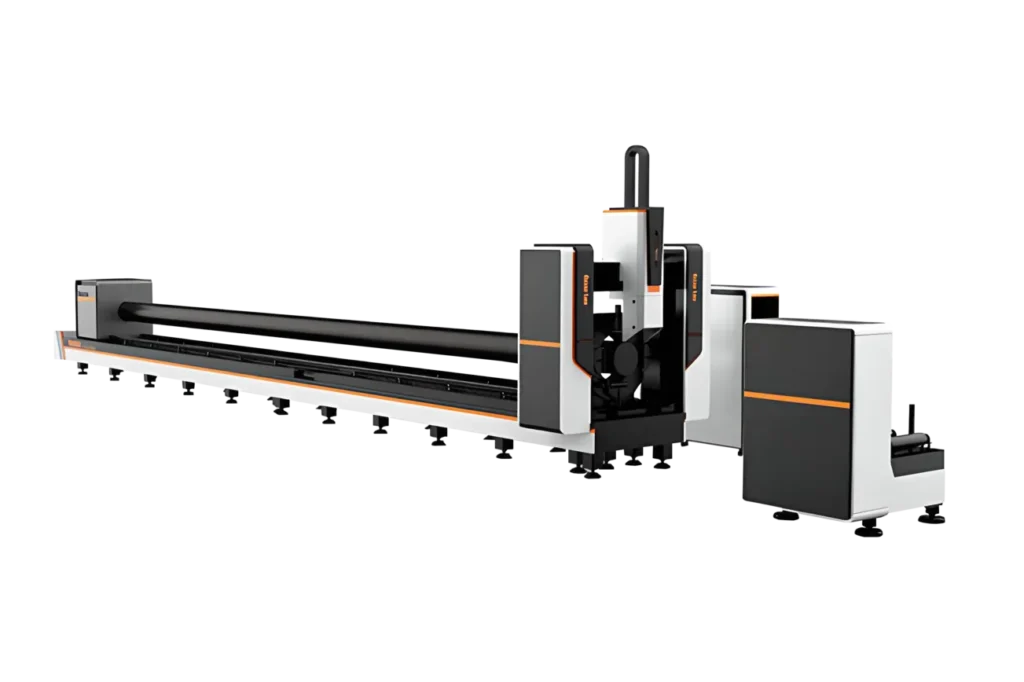

Fiber laser cutting machines utilize high-density laser beams to cut metal sheets, achieving extremely high cutting precision with very narrow kerfs. As shown in the figure, during the cutting process, the laser focuses to melt and evaporate the metal, resulting in almost no tool wear or additional chips, producing smooth and clean cutting edges. This process supports complex shape designs and micro-hole processing, making it suitable for high-precision applications such as aerospace and electronic components. It exhibits strong multi-material applicability: fiber lasers can cut various materials including carbon steel, stainless steel, aluminum, brass, plastics, ceramics, etc., and are capable of processing both thin and medium-thick plates. Speed and efficiency are significantly improved: fiber laser cutting speed is much higher than traditional methods like mechanical cutting, making it suitable for batch production and shortening delivery cycles. Modern equipment boasts a high degree of automation, enabling easy integration with automatic loading/unloading and intelligent storage systems[^4], reducing labor requirements and improving production consistency. Energy saving and economy: Compared to CO₂ lasers of the same power, fiber lasers consume less energy and offer higher energy efficiency[^5]. Furthermore, fiber laser systems have no mirror light paths, ensuring stable optical transmission with minimal maintenance requirements[^6], thereby reducing long-term operating costs. High material utilization: The extremely fine kerf width of the laser beam minimizes material waste, especially saving costs when cutting precious metals[^7]. Based on the above advantages, fiber laser cutting machines have become the ideal choice for high-precision, high-throughput applications on automated production lines.

Laser Cutting Machine

Limitations of Fiber Laser Cutting Machines

- High Initial Investment: Fiber laser cutting machines and lasers are expensive; the price of a high-power unit can be 2-3 times that of a comparable CO₂ machine[^5].

- Material Thickness Limitations: Although fiber laser cutting machines and lasers are highly capable, they are not effective for cutting ultra-thick steel plates (tens of millimeters and above). Such ultra-thick metals are typically more suitable for alternative methods like plasma or waterjet cutting[^9]. Equipment power and thickness capability must be evaluated based on actual processing needs when purchasing.

- Challenges with Highly Reflective Materials: Highly reflective metals like copper and brass reflect significant amounts of laser energy, posing risks to the light source and optical components[^10]. Although modern technology provides certain protective measures, scenarios involving extensive use of reflective materials still require extra attention to laser parameters or auxiliary surface pre-treatment.

- Safety and Environmental Factors: Laser cutting generates fumes and particulates, necessitating good ventilation and filtration systems; otherwise, workshop environment and cutting quality can be adversely affected[^11]. High-intensity lasers pose risks of eye and skin injury, requiring strict adherence to safety protocols and the use of protective equipment during operation.

- Training and Maintenance: While fiber systems require less frequent lens replacement compared to CO₂ lasers and are relatively simple to maintain[^5], operators still need specialized training. Mastering laser parameter settings and equipment maintenance procedures is crucial for ensuring cutting quality and extending equipment lifespan[^12]. Enterprises introducing this equipment should allocate time for training cycles and factor in maintenance parts costs.

Laser, Plasma, and Flame Cutting Comparison

- Laser Cutting: Renowned for high precision and the smallest heat-affected zone (HAZ)[^13]. Suitable for complex patterns and thin sheet cutting, producing smooth edges requiring almost no secondary processing. Fiber laser equipment has the highest price, but offers excellent cutting quality and high efficiency; thin sheet cutting is fast with good repeatability[^13].

- Plasma Cutting: Primarily used for cutting medium to thick conductive metals (e.g., carbon steel, aluminum plates). Equipment investment and maintenance costs are relatively moderate, but the kerf is wider, edge quality is average, it produces a larger HAZ, and often requires subsequent grinding[^14]. Plasma cutting is fast on thick materials and suitable for heavy industry scenarios; however, its precision is lower than laser, especially for thin sheets or intricate parts where it is less advantageous[^14].

- Flame Cutting (Oxy-fuel): The lowest-cost cutting method, suitable for low-cost cutting of very thick carbon steel plates. Due to its combustion-based nature, its cutting speed is far slower than laser, and the kerf is rough with the lowest precision[^13]. Only combustible metals (like plain carbon steel) can be cut, and the process produces significant slag and a wide HAZ at the cutting edge, making it unsuitable for fine processing.

Mainstream Brands and Pricing in the Chinese Market

In the domestic market, Han's Laser (大族激光), Huagong Tech (Hymson Laser 华工科技/海天激光), Bodor Laser (博多尔), Chutian Laser (楚天激光), Penta Laser (五角激光), GWK Laser (国威克激光), and Qiaolian Laser (桥联激光) are among the most renowned fiber laser cutting machine brands[^16]. These companies possess strong technical capabilities, with product lines covering entry-level to industrial-grade high-power models, widely serving industries such as automotive manufacturing, heavy industry, electronics, and home appliances. Market prices vary significantly: industry statistics indicate the overall price range for fiber laser cutting machines is approximately $13,000 to $1,000,000[^18]. Among these, low-power entry-level models (1.5~3kW) cost around $4,200~$5,000 (approx. ¥30,000~¥35,000 RMB)[^19]; while high-power laser machines (12kW and above) can range from hundreds of thousands to over a million dollars[^18]. When purchasing, users should select the appropriate power based on cutting requirements (material type, thickness, and production capacity), and pay attention to configurations offered by manufacturers (such as dual worktables, automatic loading/unloading systems) and after-sales service guarantees.

Light CNC Laser brand positions itself on compact, cost-effective fiber cutting equipment, emphasizing portable and quick-installation cutting solutions. Its products typically feature moderate power, suitable for small and medium-sized enterprises or workshops requiring rapid sheet metal cutting, with a focus on ease of operation and cost control. Among its user base, Light CNC Laser equipment is known for stability and reliability. Many buyers report that its machines match the cutting precision and quality of comparable products while offering prompt after-sales support. This brand suits small sheet metal fabrication businesses with limited budgets needing to upgrade their processes.

Procurement Recommendations

- Suitable Enterprise Types: Fiber laser cutting machines are suitable for manufacturing enterprises with high demands for product precision and surface quality, such as automotive parts processing, electronic equipment manufacturing, aerospace component processing, and precision instrument production. These enterprises typically require stable, continuous, high-volume cutting to leverage the high efficiency advantages of fiber lasers. For sporadic small-batch processing or manual workshops, the return on investment may be lower.

- Capacity and Configuration Requirements: Before procurement, clarify the cutting materials (type, maximum thickness) and expected production capacity to select the appropriate laser power and machine configuration. For high-volume production, consider dual worktables, multi-head lasers, or automatic loading/unloading systems to reduce downtime and improve production efficiency. For demanding continuous cutting operations, choose models with automatic nozzle changing or loading functions to meet high-capacity and long-running requirements.

- Technical Support and After-Sales Service: As fiber laser cutting machines are high-tech equipment, selecting a manufacturer with a robust after-sales service system is crucial. Prioritize brands offering localized training, rapid maintenance response, genuine spare parts supply, and warranty support[^20]. When signing the procurement contract, clearly define terms regarding training, repair response times, and parts supply to mitigate subsequent operational risks[^20].

In summary, fiber laser cutting machines have become important cutting equipment in modern manufacturing due to their precision, speed, and flexibility. However, procurement requires comprehensive consideration of equipment performance, investment costs, and subsequent service factors to ensure the equipment genuinely enhances production capacity and meets production requirements after deployment[^20].

References: Compiled based on manufacturer websites, industry reports, and e-commerce information[^1][^13][^14][^5][^20], etc.

[^1]: [^2]: [^3]: [^6]: [^7]: [^8]: [^9]: [^10]: [^11]: [^12]: Advantages and Disadvantages of Fiber Laser Cutting Machines - SC Machinery

https://www.shen-chong.com/zh/fiber-laser-cutting-machine-advantages-and-disadvantages/

[^4]: [^13]: [^15]: Laser Cutting vs. Flame Cutting: Which One to Choose? - Baison

https://zh-cn.baisonlaser.com/blog/laser-cutting-vs-flame-cutting/

[^5]: What is Fiber Laser Cutting? - Baison

https://zh-cn.baisonlaser.com/blog/what-is-fiber-laser-cutting/

[^14]: Advantages of Fiber Laser Cutting - Baison

https://zh-cn.baisonlaser.com/laser-cutting/

[^16]: [^17]: Top 8 China Laser Cutting Machine Brands Ranking - SC Machinery

https://www.shen-chong.com/zh/top-8-china-laser-cutting-machine-brands-ranking/

[^18]: [^20]: Best Selling Fiber Laser Cutting Machine in 2025 - 2000W - STYLECNC

https://www.stylecnc.cn/fiber-laser-cutting-machine/fiber-laser-cutter.html

[^19]: Wholesale laser light cutter For Artistic Marking and Cutting – Alibaba.com

https://www.alibaba.com/showroom/laser-light-cutter.html