How to Start a Laser Cutting Business in China

I. Industry Status and Development Trends Overview

In recent years, China’s laser cutting industry has maintained rapid growth and has become an indispensable part of the manufacturing industry.

- Laser cutting technology has evolved over decades, progressing from early CO₂ lasers and YAG lasers to the now mainstream fiber lasers, with domestic technology becoming increasingly mature.

- Industry Scale: In 2023, the market size of China’s industrial laser cutting reached approximately RMB 30.272 billion, with an average annual compound growth rate of 18.6% from 2019 to 2023.

- Downstream Applications: These are very extensive, including precision instruments, automotive parts, kitchen and bathroom hardware, electronic appliances, smart homes, sheet metal processing, etc. The penetration rate of laser cutting equipment in these fields continues to increase, with strong market demand.

- Policy Environment: The government has introduced multiple support policies, encouraging enterprises to innovate in core components such as lasers and cutting heads, and promoting the development of laser processing towards high-end, intelligent, and green directions.

- Technology and Application Trends: As laser prices decrease, the application cost of laser cutting continues to fall, making laser equipment increasingly "popularized" and accelerating the replacement of traditional cutting, stamping, and other processes.

- Currently, the performance of high-power fiber laser cutting machines is constantly improving. 8kW, 10kW, and even higher-power equipment have entered the market, capable of efficiently cutting thick plates; simultaneously, medium and low-power equipment are becoming popular among SMEs, meeting diverse processing needs. In the future, laser cutting will gain greater growth in emerging manufacturing fields such as new energy vehicles, rail transit, aerospace, and communication electronics, further expanding application scenarios.

- Overall, China’s laser cutting industry is in a stage of vigorous development with broad market space, but it also faces challenges of intensified competition and technological upgrades.

II. Laser Cutting Machine Types and Recommended Configurations

Laser cutting machines are mainly divided into three types based on the laser source: fiber laser cutting machines, CO₂ laser cutting machines, and YAG solid-state laser cutting machines. Among them, fiber laser cutting machines have become the mainstream choice for metal cutting due to their high efficiency and low maintenance costs; CO₂ lasers are more suitable for cutting and engraving non-metallic materials (such as acrylic, wood, etc.) due to their wavelength and can also be applied to some thin metal sheets; YAG lasers represent early technology with low energy conversion rates and are gradually being replaced by fiber lasers. Below, combined with the requirements of this project (budget $37,000~$57,000, approximately RMB 200,000~350,000), suitable equipment configurations are recommended:

-

Fiber Laser Cutting Machine (Main equipment for metal materials): It is recommended to purchase a fiber laser cutting machine with a power of around 1000W~2000W, with a standard cutting area of approximately 1.5m×3m, capable of covering common metal sheet sizes. The price of such equipment has dropped significantly in recent years. Currently, a complete set of a domestic 1000W fiber laser machine is quoted at around RMB 220,000, a 1500W model around RMB 250,000, and a 2000W model under RMB 300,000.

- In terms of cutting capability, a 1500W fiber laser can cut carbon steel plates with a thickness of about 1~16mm and stainless steel 1~6mm. If upgraded to 2000W, the carbon steel thickness can reach 20mm and stainless steel about 8mm.

- Considering the budget upper limit, the recommended configuration is a fiber machine of around 1500W, balancing efficiency and cost, offering high cost-effectiveness for metal sheet processing, mechanical part blanking, etc.

- When purchasing, attention should be paid to key component configurations, such as laser brand (domestic like Raycus, Maxphotonics, imported like IPG, etc.), cutting head (including capacitive sensing, anti-collision function), CNC system, servo motor, and guide rail accuracy, as these factors directly affect cutting quality and stability.

- Typically, a standard 1500W fiber laser cutting machine includes the main machine bed, laser source, chiller, dust extractor, air compressor, and other accessories, ready for use after installation and debugging.

-

CO₂ Laser Cutting Machine (For non-metal and some thin metal processing): To expand business into producing signs, acrylic products, wooden crafts, etc., it is recommended to configure a small-to-medium power CO₂ laser cutting machine. A CO₂ laser tube with around 150W power can be used to cut acrylic sheets within 20mm, wood within 15mm, and other non-metallic materials, and can also engrave text and patterns at high speed. The common working area for such machines is 1300×900mm or 1300×2500mm, and the price is relatively low – a domestic large-format 150W CO₂ laser machine can be purchased for about RMB 20,000~50,000.

- It should be noted that the capability of CO₂ lasers for cutting metal plates is limited, only suitable for thin stainless steel sheets (<2mm) or requiring oxygen assistance, with efficiency and quality inferior to fiber machines. Therefore, the CO₂ machine mainly serves as a supplement for non-metallic materials, enabling entrepreneurs to serve customer needs in advertising signage, decoration, etc. When purchasing, attention should also be paid to laser tube lifespan (generally thousands of hours, requiring regular replacement), reflector mirror quality, and personalized functions like red light positioning.

-

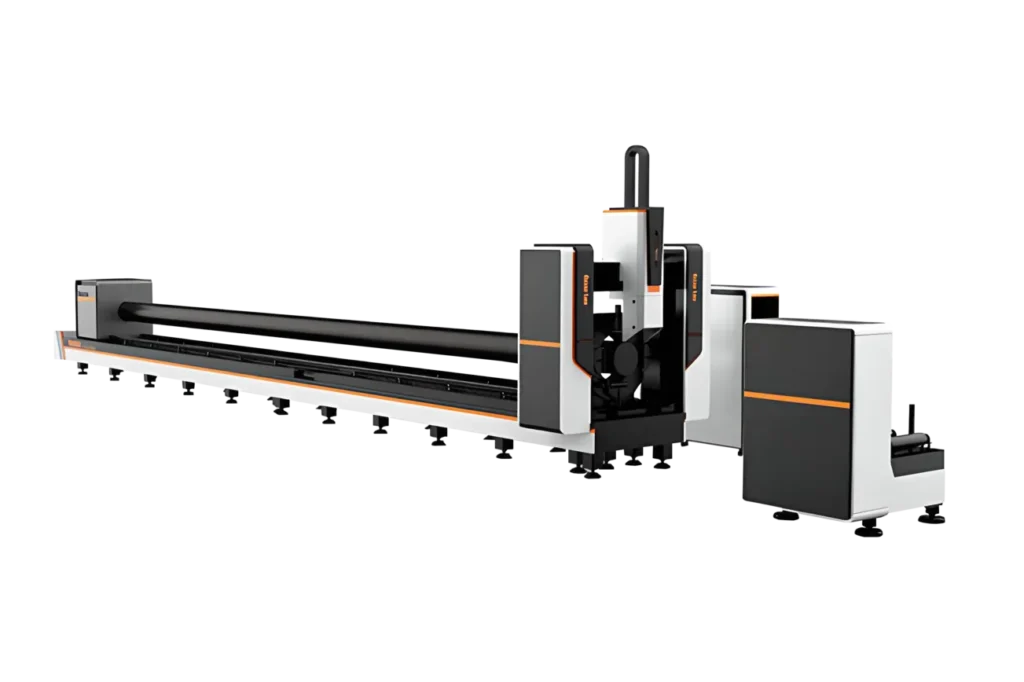

Other Equipment and Options: If the budget allows and business needs dictate, consider a combined sheet-and-tube fiber laser machine (capable of cutting both sheets and pipes/profiles), enabling the undertaking of metal pipe cutting business (such as frames for stainless steel 3D letters for advertising, furniture metal pipes, etc.). However, combined sheet-and-tube machines are relatively more expensive, generally costing more than 20% more than pure sheet machines for the same power. Given the limited startup budget, it is recommended to prioritize investing in the most versatile flatbed fiber machine. Some manufacturers offer dual-source combination machines integrating fiber and CO₂ lasers on one device to handle both metal and non-metal cutting. This equipment can achieve business diversification without increasing floor space, but its control complexity and cost are also relatively higher, requiring consideration based on market positioning. Additionally, necessary auxiliary supporting equipment for starting the business cannot be overlooked, such as: stabilized three-phase industrial power supply (fiber machines generally require 380V power), industrial chiller (to maintain suitable temperature for laser and cutting head), efficient dust and fume extraction system (with filtration device, meeting environmental requirements), air compressor and gas supply system (providing compressed air and cutting assist gases), etc. The placement and investment for these supporting facilities need to be planned in advance during factory planning. Generally, fiber laser machine manufacturers will supply the chiller and basic dust extractor, but if the factory area is large and has multiple machines, a centralized dust collector and exhaust duct design may be needed to comply with environmental emission standards (e.g., installing a fume hood + filter cartridge purification + high exhaust stack system to prevent smoke and dust pollution). In summary, the recommended solution is to purchase one approximately 1500W fiber laser cutting machine and one approximately 150W CO₂ laser cutting machine within the budget. This combined configuration can cover metal sheet metal processing as well as cutting needs for advertising and decorative materials. The preliminary budget is approximately RMB 250,000 (fiber machine) + RMB 30,000 (CO₂ machine) + auxiliary equipment costs, totaling around RMB 300,000, meeting the startup funding conditions [7].

III. Site Selection and Factory Planning Suggestions

Site Requirements: Laser cutting startups should prioritize factory locations in industrial parks or manufacturing clusters. On one hand, these areas have guaranteed power supply (providing stable three-phase industrial electricity to meet the power consumption and current requirements of laser equipment), and the factory building height and structure are suitable for installing large equipment and ventilation systems. On the other hand, proximity to potential customers (such as nearby machining factories, advertising companies, building materials markets, etc.) facilitates business acquisition and logistics transportation. Avoid locating the factory in purely residential areas or commercial centers to prevent noise and smoke generated during laser cutting from affecting the surrounding environment and causing complaints or environmental pressure. When selecting a site, also consider transportation convenience (facilitating raw material import/export and product delivery) and local industrial policy support (some development zones offer rent reductions or subsidies for advanced manufacturing startups).

Factory Scale and Layout: According to the plan, the factory area is 1000~2000 square meters. Taking the median 1500㎡ as an example, the space can be divided into the following functional areas:

- Production and Processing Area (approx. 800㎡): Place core equipment such as laser cutting machines. Two laser machines require independent operating space and safety protection zones. A fiber laser cutting machine with an exchange table occupies about 8m long x 3m wide, plus surrounding loading/unloading space. Each machine should reserve an operating area of 100~150㎡. CO₂ laser machines are smaller but still need separate enclosures to prevent laser leakage and facilitate fume extraction. Exhaust ducts and dust collection devices must be installed on the equipment to promptly remove and filter cutting fumes. The production area floor should be level and have sufficient load-bearing capacity (fiber laser machines can weigh several tons, and the material table bears significant weight when cutting thick plates). It is recommended to place laser machines close to one side of the factory building and configure a crane or hoisting equipment for moving heavy plates; if no crane is available, forklifts or electric trolleys can be used for ground handling, with aisle width sufficient for vehicle access.

- Raw Material and Finished Product Area (approx. 300㎡): Used for storing metal sheet and pipe inventory, as well as semi-finished and finished cut parts. Sheets are typically supplied in sizes like 1.5×3m or 4×8 feet (1.22×2.44m). Vertical sheet racks or pallet racks can be configured near the fiber laser machine for easy access. Sheets of different thicknesses and materials should be stored separately and labeled. The finished product area should have shelves or pallets for storing pieces and items awaiting delivery. Pay attention to keeping materials dry and ventilated to prevent rusting of steel plates or deformation of sheets due to moisture. A reasonable storage layout can reduce search and handling time, improving processing efficiency.

- Auxiliary Functional Area (approx. 200㎡): Includes office, design/programming room, equipment control room, employee rest area, etc. The office is for daily administration and customer meetings; the design room is equipped with computers and CAD/CAM programming software for processing customer drawings, nesting layouts, and issuing cutting programs. It should be close to the production area for easy communication with operators. If conditions permit, a separate equipment maintenance area can be designated within the factory to store spare parts and tools for daily maintenance (such as replacing laser mirrors, protective films, nozzles, etc.). Additionally, space should be reserved for a gas cylinder storage room (storing high-pressure cylinders for oxygen, nitrogen, etc., with attention to ventilation and safety measures) and a scrap material stacking point (regularly disposing of leftover frame scrap from cutting, which can be sold for recycling).

- Safety and Environmental Protection Facilities: In the layout, ensure proper isolation between the laser cutting area and office/living areas. Set up safety fences or partitions and post laser safety warning signs. Equip necessary fire-fighting equipment (laser cutting can ignite materials; have fire extinguishers, firewalls, etc.). The pipeline routing and main unit location of the fume extraction system should also be incorporated into the floor plan, minimizing pipeline length to improve extraction efficiency, and positioning exhaust outlets high on one side away from personnel activity areas. According to environmental requirements, install exhaust chimneys on the factory roof and regularly test exhaust emissions for compliance. In short, the 1000~2000㎡ space should be planned comprehensively: the front for office/reception, the middle for processing/production, and the side wings for storage and auxiliary facilities, ensuring smooth workflow without interference. Leave room for adding subsequent process equipment like bending machines or welding areas as the business expands.

IV. Customer Positioning and Main Application Industries

The potential customers for laser cutting services are very broad. Entrepreneurs should identify target customer groups and develop them strategically based on their own equipment capabilities and local market demand. Here are several main application industries and customer types:

- Sheet Metal Processing Industry: This is one of the most traditional and largest market segments for laser cutting. Many machinery manufacturing, industrial equipment, and automotive parts companies have significant demand for metal sheet blanking processing, including chassis, equipment enclosures, brackets, bases, automotive body parts, etc. Large manufacturers may have their own equipment, but SMEs often outsource sheet metal parts to specialized cutting shops. For entrepreneurs, positioning as a regional sheet metal processing service provider to undertake these outsourcing orders is viable. Such customers focus on cutting quality, delivery timeliness, and whether supporting processes (bending, welding, surface treatment, etc.) can be provided. Start with simple sheet cutting OEM work to build credibility, then gradually expand the service scope. Establishing cooperative relationships with nearby machinery factories and hardware factories can secure stable batch orders and improve capacity utilization.

- Advertising and Signage Industry: Advertising agencies and sign manufacturers are important customer groups for CO₂ laser cutting. They need to cut or engrave acrylic for lightboxes, sign panels, or cut stainless steel letters, nameplates, etc. Characteristics of advertising industry orders include many varieties, small batches, and strong customization (e.g., mall signs, building light letters, exhibition display boards, each with different patterns). Entrepreneurs can cooperate with local advertising companies, providing OEM services when they receive cutting-related business. Meeting such customers requires fine cutting, smooth edges (no chipping on acrylic, no burrs on metal), and precise shaping according to designs. This requires operators to skillfully adjust process parameters and conduct sample tests if necessary. Advertising companies often have tight deadlines (to match installation schedules), so quick response and timely handover are key to gaining their trust. Building a reputation within the local advertising circle can achieve stable order intake.

- Home Decoration Industry: In recent years, personalized home and commercial decoration has seen increasing use of laser-cut products, such as stainless steel or wrought iron partition grilles, staircase handrail perforated panels, metal screens, lampshades, as well as wooden hollowed ceiling panels, decorative paintings, etc. Decoration companies, custom furniture manufacturers, and interior designers may become customers. They usually require aesthetically pleasing and dimensionally precise custom parts, with materials covering both metal and non-metal. Entrepreneurs can develop some standardized products (e.g., common grille pattern panels) for display in decoration markets to attract orders. They must also perform custom cutting based on drawings provided by designers. When cooperating with decoration clients, note: 1) Protect design copyright and plan confidentiality, 2) Provide value-added services like installation coordination (e.g., pre-drilling screw holes), 3) Emphasize surface protection of finished products (avoid scratches after cutting, provide protective film covering, etc.). As decorative parts are often installed in prominent positions, quality requirements are high, allowing for correspondingly higher pricing and good profit margins.

- Machinery Manufacturing and Innovation Fields: Some small machinery factories, maker teams, and new product R&D companies also require laser cutting services for sample prototyping or small-batch part manufacturing. Examples include automotive modification parts, robot structural parts, agricultural machinery components, electronic device racks, etc. Such customers may require precision and material diversity, such as cutting aluminum alloy sheets or high-strength steel plates, or parts with complex contours and hole positions. If possessing the technical capability at the startup stage, position as a precision cutting service provider, emphasizing high precision and complex pattern cutting capabilities to attract orders from research institutions and product development companies. This requires operators to have CAD drawing and process optimization skills, interface with customer engineers on drawings, and provide process feasibility suggestions. As such orders often have high unit value but strict requirements, handle them carefully and build a good reputation. When conditions mature, e-commerce channels can be explored, placing custom laser cutting services online (e.g., Taobao, Alibaba Industrial Platform) to accept small-batch orders nationwide, but transportation and communication costs need consideration.

In summary, customer positioning should be chosen based on one’s own equipment configuration and growth areas, whether focusing deeply on one industry or adopting a "broad-spectrum" strategy serving multiple industries. For startup teams with limited budgets and manpower, it is recommended to focus on two or three niche markets initially. This ensures diversified business sources while gradually building a reputation. For example: focus on developing the local sheet metal processing and advertising/interior decoration markets – processing factory orders during the day and handling urgent orders from advertising companies at night to improve equipment utilization. As experience and resources accumulate, gradually expand the business scope to other industries.

V. Initial Operation Strategy and Team Configuration Suggestions

Personnel and Team Building: Laser cutting startups are usually small in scale initially but still require building a lean and efficient team. Typical personnel configuration and division of responsibilities are as follows:

- Entrepreneur/General Manager: Responsible for overall business operation and management. As the investor and person in charge, they need to formulate business strategies, expand customer resources, and control company finances. Initially, entrepreneurs often wear multiple hats, engaging in both market development and coordinating production processes. If the entrepreneur has a background in machining or sales, it will facilitate business development.

- Technical Supervisor/Design Engineer: Responsible for processing customer drawings, programming cutting paths, and setting process parameters. This role requires proficiency in CAD drawing and CAM nesting software, understanding the laser cutting characteristics of different materials, and the ability to adjust cutting plans based on customer requirements. For example, using nesting techniques to improve material utilization, common-edge cutting to reduce idle travel [2]. In the early stages of the team, this role can be part-time by an experienced lead operator.

- Laser Cutting Machine Operator: Responsible for daily equipment operation and maintenance. A skilled operator can independently complete tasks like loading/unloading, focusing, test cutting, and quality inspection. As this project has two different types of laser machines, ideally, one operator per machine should be assigned; if manpower is tight, one lead operator can manage both machines initially. When order volume increases, add a second operator to meet production needs. Operators need training from equipment suppliers, must strictly adhere to safety regulations (wear goggles, avoid firing lasers when the cover is open, etc.), and perform daily routine maintenance like lens cleaning and cooling water checks to ensure stable machine operation.

- Assistant/Laborer: Mainly responsible for assisting with loading/unloading, material handling, site cleaning, simple packaging, etc. Although laser cutting is mostly automated, handling large, heavy sheets requires physical labor (e.g., two people lifting plates onto the machine, sorting and stacking finished products). The assistant can also double as a warehouse keeper, managing material inventory and preparing materials according to orders. Furthermore, some cut parts may require deburring, grinding, or chamfering, which can also be done by the assistant. Hiring diligent and reliable laborers helps improve overall operational efficiency.

- Sales/Customer Service: This position is responsible for market development, customer relations, and order management. In the early stage when order volume is not high, the entrepreneur can also handle sales functions. However, as the business grows, cultivating dedicated sales personnel is beneficial for proactively acquiring more customers. Sales need to understand the company’s processing capabilities and process limitations, provide reasonable quotations, and follow up on the delivery process. Besides offline customer visits, also promote through online channels (WeChat official account, mini-programs, B2B platforms). Good customer service includes quick quotation response, providing process advice, timely communication of production progress, and properly handling after-sales issues, which is crucial for establishing a professional company image.

The initial team size can be controlled at around 5 people (including the entrepreneur), with multiple roles combined to reduce labor costs. As order volumes increase, gradually introduce more specialized personnel. Regarding incentives, core technical positions can implement piece-rate commissions or year-end bonuses, and sales positions can have performance-based commissions to boost motivation.

Operation Strategy: With the team in place, a detailed operation plan should be formulated to open up the market, control costs, and improve efficiency:

- Market Promotion and Order Acquisition: In the initial opening phase, orders can be obtained through various channels: First, leverage the entrepreneur’s network to secure the first batch of customers through acquaintances, offering trial orders or favorable terms for cooperation; Second, proactively visit nearby enterprises with relevant needs, deliver company brochures or samples (e.g., exquisite laser-cut crafts, small parts) to showcase capabilities; Third, publish information on online platforms, such as posting processing service information on Alibaba’s industrial platform or obtaining supply/demand information from local chambers of commerce and industry associations. The pricing strategy should be clear, adopting competitive quotes to secure orders, but avoid blindly undercutting prices leading to unprofitable operations. Market prices can be referenced, e.g., charging per meter of carbon steel cut based on thickness, or per hour of machine time, then adjusting appropriately based on order complexity and customer relationships.

- Quality and Delivery Management: To win a reputation, startups must focus on quality and on-time delivery. Establish quality inspection procedures, such as checking key dimensions with calipers, inspecting cut sections for slag or dross, and performing basic quality checks before each shipment to ensure defective products are not released. For delivery schedules, arrange sequencing reasonably based on order size. Strive for fast and accurate completion of small orders; for large orders, deliver in batches and communicate progress promptly with the customer. In practice, on-time delivery rate and quality pass rate are crucial criteria for customers choosing suppliers. In the early startup phase, even accepting lower profit margins is worthwhile to build a reputation. With a good reputation, profit margins can be gradually increased later.

- Cost Control: Always pay attention to the cost structure during operation, including material consumption, auxiliary consumables, electricity and water bills, labor costs, etc. Establish a material ledger, optimize nesting to improve material utilization, and minimize scrap loss (store leftover cutting scraps by category for potential use in small parts processing). Establish inventory and replacement systems for consumables like protective lenses, nozzles, electrodes, etc., to prevent downtime due to depleted small parts. Arrange production plans reasonably to avoid machine idling and frequent startups/shutdowns, saving energy. During off-seasons, try combining orders for production (multiple customer orders cut on the same sheet) or develop standard products for self-sale to ensure basic equipment utilization and spread fixed costs. Financially, prepare a cash flow budget, try to shorten the accounts receivable cycle, and request advance payments or stage payments for first-time cooperation or large orders to mitigate cash flow risks.

- Training and Improvement: Laser cutting technology develops rapidly, and the team needs continuous learning of new knowledge, such as cutting processes for new materials and new CNC software functions. Arrange for operators and engineers to regularly attend training from equipment manufacturers or peer technical exchanges to improve skill levels. Encourage frontline employees to propose process improvement suggestions, such as adjusting cutting sequences to reduce deformation or using common-edge cutting to save material, accumulating experience from practice. After stabilizing the main business, try expanding related value-added services, such as simple bending, welding assembly, laser marking, etc., to provide customers with "one-stop" processing and enhance competitiveness.

In short, the initial operation should focus on "survival and building reputation" as the core goal. Through flexible collaboration within a small team, respond quickly to the market, and refine internal management through practice, laying the foundation for subsequent scale expansion.

VI. Cost Structure, Profit Model, and Return on Investment Period Estimation

Initial Investment Composition: Based on the budget range of $37,000~$57,000, the initial investment mainly includes equipment purchase and pre-operational preparation. The table below provides a typical cost structure estimate:

| Cost Item | Estimated Amount |

|---|---|

| Fiber Laser Cutting Machine (1500W class) | ¥250,000 |

| CO₂ Laser Cutting Machine (150W large format) | ¥30,000 |

| Auxiliary Equipment (Air Compressor, Dust/Fume Extraction, etc.) | ¥20,000 |

| Site Renovation & Electrical Modification | ¥20,000 |

| Transportation, Installation, Debugging | ¥10,000 |

| Working Capital Reserve (First few months operation) | ¥50,000 |

| Total | ¥380,000 |

(Note: The above are estimates; actual costs will vary based on equipment brand and local renovation labor rates.)

From the above structure, purchasing main equipment accounts for about 70% of the total investment, followed by necessary supporting facilities and operating working capital. Entrepreneurs can adjust based on actual funding, such as choosing cost-effective domestic models to save costs or streamlining initial personnel to reduce working capital pressure. It is worth mentioning that laser equipment is a high-tech fixed asset, typically usable for 5-8 years or more (fiber laser source life can reach about 100,000 hours (^13)), so the initial investment can be amortized gradually over future years.

Operating Cost Analysis: After the business is running, monthly fixed and variable costs need careful management. Fixed costs mainly include: factory rent (varies by region, rent for 1000㎡ factory might be RMB 10,000~30,000/month), personnel wages (calculated for 5 people, monthly expense around RMB 30,000), depreciation/amortization (based on RMB 300,000 equipment over 5 years, monthly depreciation ~RMB 5,000), utilities (laser cutting consumes significant electricity; a 1500W fiber machine at full load including cooling is about 15kW, monthly electricity cost may be RMB 3,000-5,000, depending on operating hours), and office miscellaneous expenses. Variable costs include: cutting assist gas costs (e.g., oxygen for cutting carbon steel, nitrogen for cutting stainless steel; gas usage proportional to order volume; market price ~RMB 20/bottle for oxygen, RMB 80/bottle for nitrogen, or consider a small nitrogen generator for long-term cost reduction), consumables for wear parts (protective lenses, nozzles, electrodes, etc., monthly cost RMB 1,000+), and material procurement costs (if the company purchases raw materials itself to resell to customers). Generally, laser processing services have high gross profit margins because customers primarily pay for the processing value-add; material costs are often borne by the customer or settled separately. According to industry experience statistics, the gross profit margin for outsourced laser cutting processing reaches 50%~60%. This means, if external processing revenue is RMB 100,000, about RMB 40,000~50,000 covers machine depreciation, labor, utilities, and consumables, leaving RMB 50,000~60,000 as gross profit to cover fixed expenses and form net profit.

Profit Model Example: On a monthly basis, if orders from multiple industries generate monthly operating revenue of RMB 100,000, with materials provided by the customer or costs reimbursed, most of this is processing fee income. Estimating a 50% gross margin, it generates a gross profit of RMB 50,000. Deducting fixed expenses (rent 15,000 + wages 30,000 + misc. 5,000 ≈ RMB 50,000), the month may break even. If business volume increases further, e.g., monthly revenue reaches RMB 150,000, corresponding to gross profit ~RMB 75,000, then after deducting RMB 50,000 fixed costs, there is a net profit of ~RMB 25,000, corresponding to a net profit margin of about 16%. Annualized net profit would be ~RMB 300,000. At this level, the initial ~RMB 350,000 investment can be recouped in about 1.5 years. This case is relatively conservative; many laser processing shops achieve more significant returns when capacity is fully utilized. As mentioned earlier in industry data: the average profit margin for outsourced laser processing is over 50%. If business volume is sufficient, a small-to-medium power fiber laser machine can recover its cost in about a year (^14). Of course, this is an ideal value under conditions of efficient production and management. The actual payback period also depends on market conditions and company operational efficiency: if orders are scarce at the beginning, it may take a long time to cover fixed costs; but if the market is actively developed and two-shift operation (day and night) improves equipment utilization, payback can be accelerated.

Key Factors Affecting Profitability: First is capacity utilization. Laser equipment has high fixed costs; only sufficient operation can dilute these costs. Strive for daily order processing to reduce machine idle time. Second is order structure and pricing. Small-batch custom orders have high unit prices but low volume; large-batch orders have lower unit prices but high volume. Balance the two for optimal returns. Third, cost control directly affects profit margins, especially for consumables and energy consumption. Optimize processes to reduce waste. Additionally, income from value-added services is another profit source. For example, if customers need bending or welding, charge extra for handling it, or process scrap materials into crafts for retail, both can increase revenue.

Investment Return Outlook: Based on the strong demand for laser-cut products in the current Chinese market, as long as managed reasonably, the return on investment prospects are quite promising. Once the initial equipment cost is recovered, subsequent operating revenue will mainly contribute to profit, which can be used for reinvestment and expansion (e.g., purchasing higher-power equipment, adding automated loading systems). It needs to be reminded that new entrants should adopt a steady strategy in the first 1-2 years, avoiding overly optimistic expansion. Only after establishing a stable customer base and cash flow should higher development be pursued. Simultaneously, pay timely attention to market price trends, avoid getting involved in vicious price competition, and maintain reasonable profit levels through differentiated services and efficiency improvements.

VII. Common Risks and Response Suggestions

The entrepreneurial process inevitably faces various risks and challenges. Identifying them in advance and preparing countermeasures helps improve project success rates. Listed below are common risk points in the laser cutting business and corresponding suggestions:

- Market Competition Risk: The barrier to entry for the laser cutting industry is relatively low. In manufacturing-concentrated areas, there may already be many competitors, with small processing shops widespread and price competition fierce. If the local market is oversupplied, entrepreneurs face difficulties in getting orders and price pressure. Response Strategy: Strive for differentiated operations, finding unique selling points. For example, specialize in specific materials or thicknesses (if surrounding shops only cut thin sheets, you cut thick sheets), or provide value-added services (subsequent simple processing, design assistance, etc.) to escape pure price wars. Actively expand customer sources beyond the immediate town/city, possibly using the internet to accept orders from surrounding cities to broaden the market scope. Maintaining relationships with old customers is also crucial; stable repeat customers provide continuous business volume. It’s better to offer some discounts to old customers to secure long-term cooperation.

- Order Fluctuation Risk: Processing business is often correlated with manufacturing industry cycles and seasonality, leading to unstable order volumes. Idle equipment during slack seasons causes sharp revenue drops, while order surges during peak seasons may lead to delivery delays due to insufficient manpower. Response Strategy: Make flexible arrangements in business planning. During slack seasons, get through by offering discounts, developing new products, or training employees, striving to maintain basic operating rates. During peak seasons, consider temporary overtime or hiring part-time workers to catch up; for critical orders, responsible personnel should step in personally if necessary to ensure on-time completion. Additionally, strengthen a diversified customer portfolio to avoid over-reliance on a single industry or a few large customers, dispersing the risk brought by demand fluctuations. If insufficient orders are observed during a certain period, proactively seek more orders through promotions or partner introductions.

- Technology and Equipment Risk: Laser cutting equipment involves precision mechatronics and may experience failures or accuracy deviations. Prolonged downtime of core equipment directly causes business interruption and economic losses. Risk Mitigation: First, establish a maintenance plan, strictly follow the manufacturer’s recommendations to regularly replace filters, lubricate guide rails, clean lenses, preventing problems before they occur. Second, maintain spare parts inventory, such as spare optical lenses and nozzles, for quick replacement during failures. Third, establish close contact with equipment suppliers or local maintenance services, signing after-sales service agreements to ensure priority technical support when problems arise. Regularly back up software system data to prevent program loss affecting production. It is recommended to equip a UPS (Uninterruptible Power Supply) to prevent sudden power outages from affecting laser life or causing equipment abnormalities. Long-term, consider purchasing a second identical machine as redundancy after profitability is achieved, improving risk resistance.

- Safety and Environmental Protection Risk: Laser cutting involves high temperatures and high-energy beams. Improper operation may cause safety accidents (e.g., igniting materials, burning personnel). Simultaneously, cutting generates metal fumes and odors. Improper handling can lead to environmental violations or harm employee health. Preventive Measures: Establish strict safety operating procedures and provide onboarding training for employees, emphasizing prohibitions like operating lasers unsupervised, timely removal of flammable materials, and proper use of personal protective equipment. The factory must be equipped with a fire protection system (smoke detectors, fire extinguishers), regularly checking their effectiveness. For environmental protection, install and maintain ventilation and dust extraction systems. Add purification equipment like enclosures or activated carbon adsorption if necessary to ensure exhaust emissions meet standards. Provide dust masks for frontline employees and enhance workshop ventilation. Regarding environmental permits, understand local environmental requirements for laser cutting projects in advance, complete the necessary Environmental Impact Assessment (EIA) filing or approval procedures to avoid being ordered to rectify or suspend operations due to non-compliance.

- Financial and Cash Flow Risk: The initial startup investment is large, and the payment collection cycle is uncertain. Poor cash planning may lead to a cash flow crisis. Situations like customer payment delays, sudden raw material price increases, or major equipment failures requiring expensive repairs put pressure on finances. Response Suggestions: Reserve funds and arrange financing. Set aside a portion of working capital within the budget for emergencies. If self-funding is tight, apply for bank credit lines, microloans, or introduce partners for investment in advance to increase financial flexibility. Conduct credit checks on customers. For large orders from new customers, request advance payment of a certain percentage to avoid excessive credit exposure. Implement staged payment strategies, e.g., collecting material fees and processing fees in stages for large orders, reducing accounts receivable risk. Closely monitor monthly income and expenses, set a minimum cash reserve red line. Once approaching the warning level, promptly reduce controllable expenses or seek financing. Don’t wait for a cash flow break to act.

- Talent Loss and Management Risk: The laser cutting industry relies heavily on technical personnel. If core operators or technical engineers leave, production may be affected or customers lost. Additionally, small team startups may face management issues like insufficient coordination and communication. Response Strategy: Implement incentive measures to retain key employees. If possible, allow technical backbone staff to participate in profit sharing or equity incentives to increase their sense of belonging. Foster a good working atmosphere, respect employees’ professional opinions, maintain reasonable work schedules, and reduce dissatisfaction caused by excessive overtime. Establish basic management systems. Even with few people, clarify responsibilities and processes to avoid bottlenecks in orders, accounting, or procurement caused by negligence. The entrepreneur should lead by example, being both a leader and a colleague, resolving team conflicts promptly. Consider hiring a part-time finance or HR assistant to handle administrative tasks, allowing the core team to focus on business.

- Other Policy and Force Majeure Risks: Pay attention to new national and local policies regarding SMEs, environmental safety, labor employment, etc. Be prepared for aspects like applying for tax incentives, compliant payment of social insurance and housing fund, and risks of shutdowns caused by force majeure like pandemics. Build risk awareness; purchasing property insurance, machinery insurance, employer liability insurance, etc., for the company is also wise. Insurance payouts can reduce losses if problems occur.

In conclusion, starting a laser cutting business in China presents both opportunities and challenges. Entrepreneurs should be guided by steady operations. On one hand, seize the market opportunities brought by industry prosperity and actively expand the business territory. On the other hand, as described above, do a good job in risk control and internal capability building. With solid planning and execution, leveraging China’s vast manufacturing market and the spirit of diligence and innovation, this laser cutting startup project within the budget scale has the potential to achieve long-term development and provide strong support for the domestic manufacturing chain. [14]

References:

1 2 3 4 5 6 Analysis of the Development Status and Trends of China’s Laser Cutting Industry in 2024, Rapid Increase in Application Penetration Rate of Laser Cutting Equipment, Continuous Expansion of Application Scenarios "Chart"_Huaon Intelligence Network_Huaon Industry Research Institute

https://www.huaon.com/channel/trend/1046161.html

7 10 11 How Much Does It Cost to Run a Laser Cutter? – cn.accuripressbrake.com

https://cn.accuripressbrake.com/how-much-does-it-cost-to-run-a-laser-cutter

8 How to Choose the Right Power for a Fiber Laser Cutting Machine? – SC Machinery

https://www.shen-chong.com/zh/how-to-choose-suitable-fiber-laser-cutting-machine-power/

9 13 14 Is Investing in a Laser Cutting Machine Profitable? _Laser Cutting Machine – Dema

https://www.demaindustry.com/post/626.html

12 Laser Cutter Guide: Tips and Tricks – ADH Machine Tool

https://www.adhmt.com/zh/%E6%BF%80%E5%85%89%E5%88%87%E5%89%82%E6%9C%BA%E6%8C%87%E5%8D%97/

One Response

I really like it when folks come together and share opinions. Great blog, stick with it!