Advantages of Laser Cutting Machines

As a high-precision, high-efficiency cutting technology, laser cutting machines have been widely applied in sheet metal processing and the advertising industry in recent years. Compared with traditional plasma cutting and waterjet cutting, laser cutting features non-contact cutting heads, extremely narrow kerfs, and a small heat-affected zone, enabling high-precision, rapid, and flexible processing effects [1].

-

High Cutting Precision, Narrow Kerf: The laser beam is focused into an extremely fine spot, resulting in a very narrow kerf (0.1~0.3mm) with straight, vertical sides on the cut edge, free from mechanical stress and burrs [1]. Typically, the machining accuracy of laser-cut parts can reach ±0.05~0.2mm, significantly better than plasma cutting (usually 0.5~1mm accuracy) [1]. High-precision cutting not only reduces subsequent grinding and trimming work but also minimizes material waste and process costs to the greatest extent [1].

-

Fast Cutting Speed, High Efficiency: Laser cutting is extremely efficient for thin sheet processing. For example, a 1200W fiber laser can cut 2mm carbon steel plate at speeds up to 600 cm/min (approx. 6 m/min) [5], far exceeding the speeds of plasma and waterjet cutting for the same thickness. High-speed cutting significantly shortens production cycles, increases capacity, and is suitable for batch production. Combined with automatic loading/unloading systems and intelligent nesting software, laser cutting enables continuous unmanned processing, further improving capacity utilization [6].

-

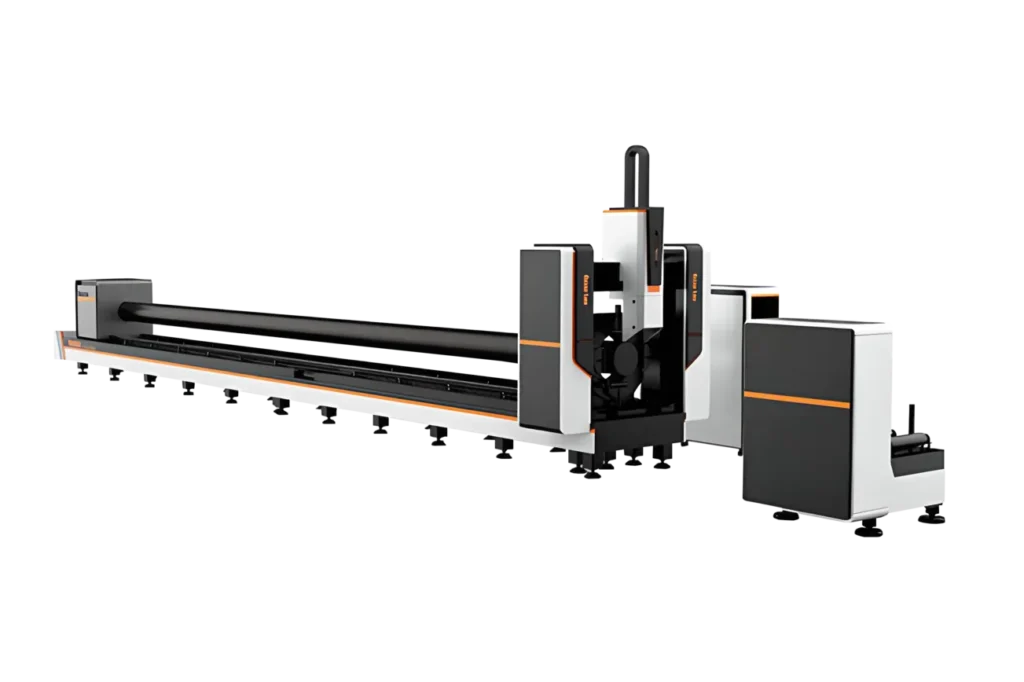

Wide Material Compatibility, Broad Applicability: Laser cutting processes both metal and some non-metal materials, including various metals such as carbon steel, stainless steel, aluminum, and copper, as well as non-metal materials like plastics, acrylic, leather, and fabrics [7]. Unlike plasma cutting, which is only suitable for conductive metals, laser cutting can perform precise cuts on organic materials (e.g., acrylic, fabric). Compared to waterjet cutting, laser cutting offers higher efficiency and better kerf quality for thin sheet processing. Laser cutting machines can also process large-format sheets or tubes, offering flexibility without the need for mold development [8].

-

Low Operating Costs, Energy Savings: Modern fiber laser cutting machines achieve electro-optical conversion efficiencies of 25%~30%, far higher than traditional CO₂ lasers (approx. 8%~10%). High efficiency means less power consumption for the same output, reducing total energy consumption by 3~5 times compared to traditional cutting methods [9]. The laser cutting process does not consume large amounts of consumable gases or fuel, and maintenance is simple, resulting in lower overall energy and consumable costs [10]. For example, when blowing gas to cut thin metal sheets, the electricity cost per unit operating hour for a high-performance fiber laser cutting machine is only about 6~10 RMB [11].

Advantages in Sheet Metal Processing

In the field of sheet metal processing, laser cutting machines have become one of the core equipment. Traditional sheet metal workshops rely on processes such as shearing, stamping, and bending, which not only involve high investment in mold costs but also offer poor processing flexibility. Introducing laser cutting significantly improves processing technology: lasers require no molds; changing the program allows processing different patterns, greatly shortening product development cycles and upfront investment [1].

- Excellent Kerf Quality: Laser-cut sheet metal edges are smooth and clean, generally requiring no secondary processing [1]. Compared to plasma or oxygen cutting, laser cutting has a small heat-affected zone and causes minimal plate deformation, preventing part warping. This is especially suitable for materials sensitive to deformation, such as stainless steel and thin steel plates [1].

- High Processing Precision: The laser cutting head is non-contact with the workpiece, eliminating precision degradation due to tool wear. It offers high repeat positioning accuracy and good consistency for batch parts [4]. For complex contours or fine structures, laser cutting can also achieve precise forming, adapting to any planar graphics on sheets and 3D cutting requirements [12].

- Improved Production Efficiency: Laser cutting offers high flexibility. Combined with automatic nesting software, it optimizes layout to improve material utilization [1]. Unlike stamping or shearing, laser cutting does not require dedicated dies for simple shapes, resulting in very low upfront investment and greater flexibility and efficiency. Additionally, automated loading/unloading systems ensure continuous operation of the cutting center, enabling 24-hour operation and further boosting production efficiency [13].

- Cost and Maintenance Advantages: Compared to traditional plasma and flame cutting machines, laser cutting machines require fewer consumables. There is no need to replace electrodes or nozzles, leading to low maintenance costs. Fiber lasers have a long service life, reaching approximately 100,000 hours [10], and are almost maintenance-free, saving costs on frequent part replacements. Overall, laser cutting in sheet metal processing can reduce processing steps, lower labor costs and material loss, achieving simultaneous improvements in capacity and quality [1].

Application Advantages in the Advertising Industry

In the advertising industry (e.g., signs, engraved letters, display decorations), materials are diverse and demand high surface finish quality. Laser cutting, with its advantages of multi-material applicability, high precision, and smooth edges, has become the preferred technology for advertising processing.

- High Precision, No Rework: Laser cutting can process various materials like metal sheets, acrylic boards, and PVC boards. Unlike traditional manual cutting which suffers from low precision, laser cutting achieves high precision and complex pattern processing. The cut edges are flat and smooth, almost eliminating the need for manual edge trimming, greatly reducing rework rates and labor input. After adopting laser cutting, advertising companies produce lightbox letters and engraved panels with excellent surface precision and aesthetics, enhancing advertising quality and visual appeal.

- Handles Complex Graphics Effortlessly: Laser cutting can process any curve and contour, completing complex shapes in one pass that are impossible with traditional methods. Examples include intricate storefront lettering, delicate decorative engravings, and 3D shape cutting. Lasers achieve these with high precision, expanding design and creative possibilities and enhancing the expressiveness of advertising products.

- High Efficiency, Low Cost: Fiber laser cutting machines offer high power and fast response, making them particularly suitable for thinner advertising boards. A certain 10kW-class laser cutting machine, with air-assisted cutting, can process over 6 meters of thin sheet per minute [1], with an hourly electricity cost of only 6~10 RMB [2]. This level of efficiency and energy consumption allows advertising processing enterprises to significantly reduce processing costs and shorten delivery cycles.

- Stable and Durable: Advertising processing often requires long periods of repetitive cutting. Fiber lasers offer extremely high stability and ultra-long life (common lifespan up to 100,000 hours) [3], with key components requiring no maintenance. This means the equipment can operate stably around the clock without frequent shutdowns for maintenance, helping advertising manufacturers maintain continuous production capacity and reduce maintenance management burdens.

Technological Development Trends and Core Competitiveness

In recent years, continuous innovation in laser cutting technology has further solidified its competitive advantage in manufacturing. Future trends include the development of fiber lasers towards higher power, intelligence, and domestic production, as well as deep integration with automation and digital technologies [4], [5]. These trends will further enhance the efficiency, precision, and sustainability of laser cutting.

- High-Power Fiber Lasers: Industry demand drives the development of high-power lasers, enabling laser cutting to continuously break through effective processing thickness limits. High-power lasers maintain good cutting quality on thicker materials while high-efficiency designs achieve dual improvements in efficiency and performance [6], [7].

- Intelligence and Automation: Laser cutting equipment is integrating with robotics and sensor network technologies to achieve functions like automatic tool changing, online monitoring, and remote control. Seamless integration of laser systems with CNC systems and scientific management enables automatic nesting and fixed-point loading/unloading, significantly reducing manual intervention [8].

- Intelligent control makes the processing process more stable and controllable, further improving processing quality and production efficiency.

- High-Precision Control and New Material Applications: With advances in control algorithms and software, laser cutting can achieve dynamic optimization of key process parameters (e.g., focal position, cutting speed, gas flow regulation), ensuring more stable cutting performance. Simultaneously, research into new laser technologies and beam delivery techniques will expand laser compatibility with highly reflective or special materials, opening up applications on a wider range of materials.

- Energy Efficiency and Environmental Protection: Fiber laser cutting requires no auxiliary liquids or abrasives, resulting in clean cuts without waste slag, reducing pollution in the production environment. Future laser cutting equipment will focus more on energy utilization efficiency and green, eco-friendly design. By improving photoelectric conversion efficiency and recycling cutting fumes, it will contribute to energy conservation and emission reduction in manufacturing [9].

In summary, laser cutting, with its core competitiveness of high efficiency, high precision, low energy consumption, and easy maintenance, demonstrates significant advantages in sheet metal processing and advertising manufacturing. With the continuous development of fiber laser technology and intelligent manufacturing, laser cutting will bring users higher production efficiency and better processing quality, representing an important development direction for the future of manufacturing [10].

References: Industry reports and technical literature related to laser cutting technology [11], [12], [13].

- Introduction to the use of laser cutting in the sheet metal industry Cutting Process Consulting Laser Manufacturing Network

https://www.laserfair.com/jiguangyingyong/201906/26/397.html - [13] Advantages and disadvantages of fiber laser cutting machine

https://www.shen-chong.comzh/fiber-laser-cutting-machine-advantages-and-disadvantages/ -

-

- Water cutting, plasma cutting, laser cutting, wire cutting, do you know them all? How to choose?

https://www.hdwaterjet.cn/h-nd-350.html

- Water cutting, plasma cutting, laser cutting, wire cutting, do you know them all? How to choose?

-

-

-

- Plasma cutting vs. laser cutting

https://www.hypertherm.com/zh/resources/more-resources/blogs/plasma-cutting-vs-laser-cutting/

- Plasma cutting vs. laser cutting

-

-

-

- Advertising fiber laser cutting machine in the advertising industry application advantages

https://www.gyclaser.com.cn/gyc_n1570

- Advertising fiber laser cutting machine in the advertising industry application advantages

-

- CO2 vs. Fiber Laser Cutting Machines: Which is Right for You?

https://www.stylecnc.cn/industry-news/Fiber-laser-cutting-machine-VS-CO2-laser-cutting-machine.html - China’s laser cutting industry development status and trend analysis in 2024, laser cutting equipment application penetration rate is rapidly increasing, the application scene continues to expand

https://www.huaon.com/channel/trend/1046161.html - Laser Cutting Industry Analysis_Laser Cutting Market Research_Laser Cutting Industry Report

https://pdf.dfctw.com/pdf/H3_AP202410151640309723_1.pdf?1729022015000.pdf