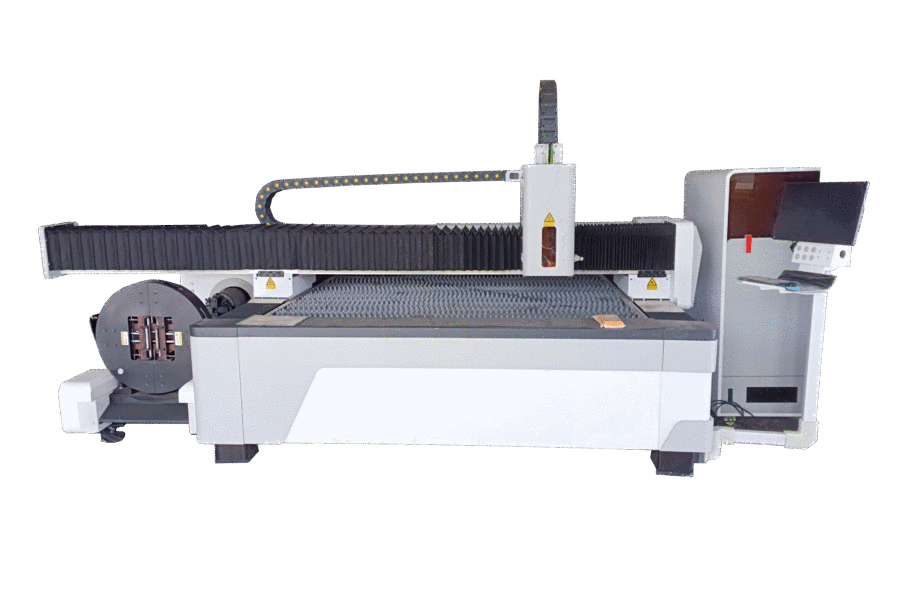

Affordable High-Precision 3015 Industrial Fiber Laser Cutting Machine

Explore the 3015 Industrial Fiber Laser Cutting Machine, a top-selling laser machine designed for flat precise metal cutting. Ideal for various metal thicknesses, this versatile and cost-effective solution is perfect for the metal cutting industry. Support 1kw, 1.5kw, 2kw, 3kw, 4kw, 6kw, 12kw laser power source. Is the most stable and top sale models among all fiber laser cutters. can add optional rotary to cut various pipe and tube, also can add exchange table to raise working effieincy, if need, can add one full cover to protect labor and clean the working dust.

3015 Fiber Laser Cutting Machine - The Best Choice for High-Precision Metal Cutting

Model: LT3015F

Working area: 3000*1500mm(6000*1500mm, 6000*2000mm ,12000*2000mm.etc for optional)

Support Laser Power: 1kw, 1.5kw, 2kw, 3kw, 6kw,12kw

Price Range: $30 00 – $850 00

Warranty time: 1 year for the whole machine

Delivery time: 7-10 workdays

Technical Support Time: Free Lifetime for All Clients

Machine Videos

Technical Parameter

| Machine Model | LT3015-F (LT6015-F, LT4020-F, LT6020-F, LT12020-F.etc) |

|---|---|

| Working area | 3000*1500mm (6000*1500mm, 4000*2000mm, 6000*2000mm, 12000*2000mm.etc) |

| Controller | FSCUT Controller (Weihong Controller for optional) |

| Motor driver | LEADSHINE Servo motor (Japanese Fuji servo motor / YASKAWA servo motor as optional) |

| Laser head | Raytools laser head( FSCUT, Weihong, BOCI.etc for optional) |

| Fiber power supply | 1kw/1.5kw/2kw/3kw/6kw/12kw for optional |

| Helical Rack | YYC |

| Guild | KING TEK (HIWIN guild for optional) |

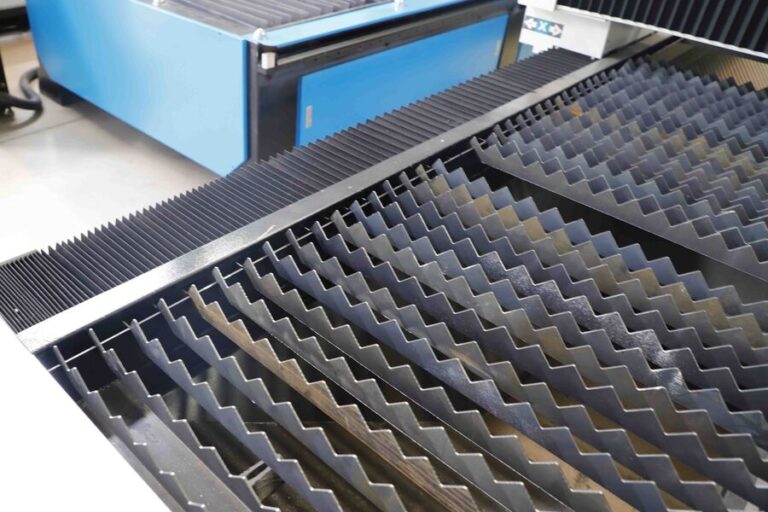

| Worktable | Tooth blade worktable |

| Cooling parts | Chinese famous brand HANLI dual cooling chiller is more professional and can work for a long time. |

| Graphic format supporting | PRO/E.UG, Solidworks |

| Position efficiency | ±0.05mm |

| Rep.Position efficiency | ±0.03mm |

| Working Speed | 60-100m/min |

| Working air | Nitrogen,Oxygen,Air |

| Machine frame | Overall aviation aluminum profile design, faster and more accurate operation5 Heavy-duty body, with multi-faceted professional vacuum duct holes |

| Operate computer | Industrial computers with long screens are more convenient to use and more in line with the habit of using mobile phones |

| Metal Cover | Luxury models are fully surrounded by sheet metal, and put in the workshop to enhance the level of the factory. |

| Water air pipe | Pressure-resistant and explosion-proof water pipes and air pipes ensure the safe and stable operation of the machine under special circumstances. |

| Rack | High-precision grinding rack to ensure higher accuracy. |

| Towline | Fully enclosed fire protection is a high and low temperature towline, which ensures the safety of the operation site. |

| Dust cover | X Y axis flame retardant dust cover. |

| Electrical components | France Schneider Electric electrical components |

| Protect functions | Highly flexible, anti-breaking, cable that can shield external interference signals |

| Oil system | Fully automatic oiling system |

| Wheel Feed System | Easy-to-feed bull's eye wheel |

| Adjustable body feet | High-strength body leveling feet, more suitable for different customer sites , To ensure high-quality running cutting |

| Blade worktable | professional serrated blade (with anti-scratch iron plate function) |

| Soft packing | Air cushion film fresh-keeping film pearl cotton three-layer soft packaging standard |

| Total Power | 12KW/H-98KW/H( different laser power will cause different total power) |

| Voltage | 380V 50HZ |

| Machine size | 4400*2280*1850mm |

| Packed size | 4650*2280*2100mm |

| Net Weight | 2800kgs |

| Gross Weight | 3200kgs |

Machine Features

Unique Advantages: Adopt to use the one-body structure, Machine’s all important driving system and metal transmission system be installed in one body together, so can offer the higher cutting precision and best stability. A strong frame can support the machine equipped with 1kw, 1.5kw, 2kw, 3kw 6kw and even 12kw higher power laser source. It is one popular model of fiber laser cutter which has the biggest use range and the highest working stability. Besides, this machine’s regular models also include 6000*1500mm, 4000*2000mm, and 6000*2000mm. etc, the customer could adopt the most suitable models according to exact working requirements.

PC Controller: Adopt the Professional Industrial Computer, and support to install popular controller system, such as FSCUT, Weihong, Raytools. etc. Has high immunity to interference.

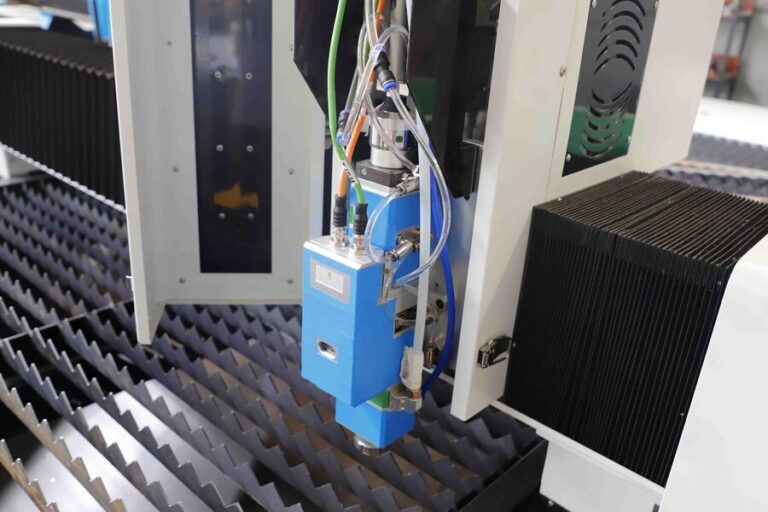

Fiber Laser Head: Intelligent high precision fiber laser head, can support to cut almost all the materials with best effect. Mainly use the Raytool, Boci, FSCUT brand.

Fiber Laser Power Supply: Perfect Max fiber laser power supply, can offer the high stable fiber laser path for working on various styles and thickness’ metal sheet. Could also adopt the suitable power laser source according to the below different laser power cutting functions.

| Different Laser Powers' Cutting Function Table | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Laser Power | 1.5KW | 2KW | 3KW | 4KW | 6KW | 12KW | 20KW | 30KW | 40KW | 60KW | |

| Materials | Thickness(mm) | Speed (m/min) | |||||||||

| Carbon Steel (O2) | 1 | 15-20 | 24-30 | 30-40 | 33-43 | 35-44 | 60-75 | 65-85 | 70-90 | 80-95 | 90-100 |

| 2 | 4.0-5.0 | 4.7-6.5 | 4.8-7.5 | 15-25 | 20-28 | 28-40 | 50-75 | 60-80 | 70-80 | 78-88 | |

| 3 | 3.0-4.0 | 3.0-4.8 | 3.3-5.0 | 7.0-12 | 13-17 | 18-30 | 45-65 | 50-75 | 55-80 | 65-90 | |

| 4 | 2.3-2.8 | 2.8-3.5 | 3.0-4.2 | 3.0-4.0 | 3.0-4.5 | 3.5-5.5 | 5-7.0 | 6.5-10 | 40-70 | 50-80 | |

| 5 | 1.8-2.3 | 2.2-3.0 | 2.6-3.5 | 2.7-3.6 | 3.0-4.2 | 3.3-4.8 | 5.3-6.5 | 6.5-9.0 | 30-55 | 42-65 | |

| 6 | 1.6-2.0 | 1.8-2.6 | 2.3-3.2 | 2.5-3.4 | 2.5-3.5 | 3.0-4.2 | 4.0-5.5 | 6.0-9.0 | 20-25 | 35-45 | |

| 8 | 1.2-1.5 | 1.2-1.8 | 1.8-2.6 | 2.0-3.0 | 2.2-3.2 | 2.5-3.5 | 3.5-5.0 | 5.5-8.5 | 17-20 | 30-40 | |

| 10 | 0.6-0.8 | 1.1-1.3 | 1.2-2.0 | 1.5-2.4 | 1.8-2.5 | 2.2-2.7 | 3.5-4.7 | 5.0-8.0 | 15-20 | 20-25 | |

| 12 | 0.5-0.6 | 0.9-1.2 | 1.0-1.6 | 1.2-2.8 | 1.2-2.0 | 1.2-2.1 | 2.0-4.0 | 4.0-7.3 | 9.0-12 | 10-14.5 | |

| 14 | -- | 0.7-0.8 | 0.9-1.4 | 0.9-1.2 | 1.2-1.8 | 1.7-1.9 | 1.7-3.0 | 3.7-6.0 | 8.0-10.5 | 9.0-13.5 | |

| 18 | -- | 0.4-0.6 | 0.6-0.8 | 0.6-0.9 | 0.6-0.9 | 1.0-1.8 | 1.5-2.3 | 3.3-5.0 | 6.5-9.5 | 7.5-11.5 | |

| 20 | -- | 0.2-0.4 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.6-1.5 | 1.5-2.3 | 2.4-4.0 | 6.0-8.5 | 6.8-10.2 | |

| 25 | -- | -- | 0.2-0.5 | 0.3-0.55 | 0.3-0.55 | 0.5-1.1 | 1.0-1.5 | 2.0-3.5 | 5.1-8.3 | 6.1-9.5 | |

| 30 | -- | -- | -- | -- | 0.2-0.5 | 0.3-0.9 | 0.8-1.1 | 1.5-2.5 | 3.0-4.5 | 5.0-8.5 | |

| 40 | -- | -- | -- | -- | -- | 0.2-0.6 | 0.6-1.0 | 1.2-2.0 | 2.5-3.0 | 3.8-6.0 | |

| 50 | -- | -- | -- | -- | -- | -- | 0.5-0.8 | 0.8-1.7 | 2.0-3.0 | 3.2-5.0 | |

| 60 | -- | -- | -- | -- | -- | -- | 0.4-0.7 | 0.5-1.5 | 1.0-1.5 | 2.1-4.5 | |

| 70 | -- | -- | -- | -- | -- | -- | 0.3-0.5 | 0.4-0.7 | 0.6-1.3 | 1.5-2.5 | |

| 80 | -- | -- | -- | -- | -- | -- | -- | 0.2-0.5 | 0.3-1.0 | 0.6-1.5 | |

| 90 | -- | -- | -- | -- | -- | -- | -- | -- | 0.2-0.4 | 0.4-1.0 | |

| Stainless Steel (N2) | 1 | 20-25 | 24-36 | 30-35 | 32-45 | 45-52 | 60-72 | 72-100 | 80-105 | 85-110 | 95-130 |

| 2 | 8.0-10.0 | 6.0-10.0 | 13-21 | 16-28 | 20-33 | 35-45 | 45-70 | 55-80 | 75-98 | 90-118 | |

| 3 | 4.5-5.5 | 2.2-3.5 | 6.0-10 | 7.0-1.5 | 15-22 | 20-30 | 38-50 | 45-70 | 55-80 | 85-100 | |

| 4 | 3-3.5 | 1.2-1.6 | 4.0-6.0 | 5.0-8.0 | 10.0-15.0 | 15-22 | 25-35 | 38-65 | 47-70 | 68-92 | |

| 5 | 1.5-2.0 | 0.6-0.75 | 3.0-5.0 | 3.5-5.0 | 8.0-12 | 10-18 | 20-30 | 30-63 | 40-66 | 55-83 | |

| 6 | 0.7-0.9 | 0.6-0.75 | 2.0-4.0 | 2.5-4.5 | 4.8-8.0 | 8-12 | 15.0-25.0 | 25-53 | 35-60 | 43-60 | |

| 8 | -- | 0.5-0.6 | 1.5-2.0 | 1.2-2.0 | 3.0-4.0 | 5.0-7.5 | 8.0-12.0 | 20-45 | 30-53 | 35-53 | |

| 10 | -- | 0.4-0.5 | 0.6-0.8 | 0.8-1.2 | 1.6-2.5 | 3.0-7.0 | 6.0-10.0 | 20-32 | 25-40 | 30-50 | |

| 12 | -- | -- | 0.4-0.6 | 0.5-0.8 | 0.8-1.5 | 2.5-3.9 | 4.0-6.0 | 15-25 | 18-30 | 20-30 | |

| 14 | -- | -- | -- | 0.4-0.6 | 0.6-0.8 | 1.8-2.8 | 3.5-6.0 | 13-20 | 15-25 | 17-27 | |

| 18 | -- | -- | -- | -- | 0.4-0.6 | 1.2-1.8 | 1.2-2.2 | 8.0-12.0 | 10.0-13.0 | 13-18 | |

| 20 | -- | -- | -- | -- | 0.3-0.5 | 0.9-1.5 | 1.3-1.8 | 6.0-8.0 | 7.3-10 | 8.0-13 | |

| 25 | -- | -- | -- | -- | 0.2-0.4 | 0.6-0.7 | 0.6-1.2 | 4.0-5.5 | 5.0-7.5 | 6.0-9.1 | |

| 30 | -- | -- | -- | -- | 0.2-0.4 | 0.3-0.6 | 0.5-1.0 | 2.5-3.9 | 3.5-4.9 | 4.0-5.8 | |

| 40 | -- | -- | -- | -- | -- | 0.3-0.5 | 0.3-0.6 | 1.8-2.8 | 2.8-4.0 | 3.6-4.9 | |

| 50 | -- | -- | -- | -- | -- | 0.3-0.4 | 0.2-0.5 | 1.3-1.8 | 1.3-2.8 | 2.3-3.3 | |

| 60 | -- | -- | -- | -- | -- | 0.2-0.3 | 0.2-0.4 | 0.5-0.8 | 0.9-1.8 | 1.9-2.3 | |

| 70 | -- | -- | -- | -- | -- | -- | 0.2-0.35 | 0.5-1.0 | 0.6-1.0 | 1.2-1.7 | |

| 80 | -- | -- | -- | -- | -- | -- | -- | 0.2-0.4 | 0.5-0.8 | 0.5-1.0 | |

| 90 | -- | -- | -- | -- | -- | -- | -- | -- | 0.2-0.3 | 0.2-0.7 | |

| Aluminum (N2) | 1 | 12.0-16.0 | 15-20 | 25-38 | 35-45 | 42-55 | 45-50 | 55-65 | 60-70 | 75-95 | 75-110 |

| 2 | 4.0-5.0 | 7.0-10.0 | 10.0-18.0 | 13-24 | 20-40 | 30-35 | 33-45 | 55-65 | 70-85 | 84-98 | |

| 3 | 1.5-2.5 | 4.0-6.0 | 6.5-8.0 | 7.0-13 | 15-25 | 20-25 | 25-35 | 40-55 | 60-77 | 73-90 | |

| 4 | 1-1.3 | 2.0-3.0 | 3.5-5.0 | 4.0-5.5 | 9.5-12 | 18-20 | 15-25 | 38-50 | 53-67 | 63-83 | |

| 5 | -- | 1.2-1.8 | 2.5-3.5 | 3.0-4.5 | 5.0-8.0 | 14-16 | 13-20 | 35-45 | 43-60 | 52-77 | |

| 6 | -- | 0.7-1.0 | 1.5-2.5 | 2.0-3.5 | 3.8-5.0 | 10-12 | 9.0-12 | 25-35 | 36-58 | 47-68 | |

| 8 | -- | 0.6-0.8 | 0.7-1.0 | 0.9-1.6 | 2.0-2.5 | 6.0-8.0 | 4.5-6.5 | 20-30 | 28-48 | 32-57 | |

| 10 | -- | -- | 0.4-0.7 | 0.6-1.2 | 1.0-1.5 | 4.0-6.0 | 2.8-4.0 | 15-24 | 20-35 | 25-45 | |

| 12 | -- | -- | -- | 0.4-0.6 | 0.8-1.0 | 2.0-3.0 | 1.9-2.5 | 13-20 | 18-30 | 20-37 | |

| 16 | -- | -- | -- | -- | 0.5-0.8 | 1.3-2 | 1.5-2.0 | 10.0-15.0 | 13-27 | 16-30 | |

| 20 | -- | -- | -- | -- | -- | 0.8-1.2 | 0.8-1.2 | 9.0-12 | 11-20 | 13-28 | |

| 30 | -- | -- | -- | -- | -- | 0.3-0.8 | 0.3-0.7 | 6.0-10.0 | 9.3-16.7 | 11.2-22.3 | |

| 40 | -- | -- | -- | -- | -- | 0.2-0.4 | 0.3-0.5 | 4.0-6.0 | 7.7-13.7 | 8.2-18.3 | |

| 50 | -- | -- | -- | -- | -- | 0.1-0.2 | 0.2-0.4 | 2.0-3.0 | 5.8-10.7 | 6.8-15.7 | |

| 60 | -- | -- | -- | -- | -- | -- | 0.2-0.3 | 1.3-1.8 | 3.8-8.3 | 4.3-10.5 | |

| 70 | -- | -- | -- | -- | -- | -- | 0.1-0.2 | 0.3-0.8 | 2.5-6.7 | 2.3-7.2 | |

| 80 | -- | -- | -- | -- | -- | -- | -- | 0.2-0.3 | 1.0-3.7 | 0.9-3.1 | |

| Brass (N2) | 1 | 9.0-12.0 | 10.0-16.0 | 20-35 | 25-35 | 35-45 | 50-60 | 75-85 | 78-88 | 80-90 | 85-95 |

| 2 | 4.0-5.0 | 5.0-6.0 | 6.0-10 | 8.0-12 | 20-30 | 33-40 | 40-55 | 55-65 | 68-77 | 72-87 | |

| 3 | 1.5-2.0 | 2.5-4.0 | 4.0-6.0 | 5.0-8.0 | 12.0-18.0 | 15-23 | 32-50 | 40-55 | 45-58 | 50-60 | |

| 4 | -- | 2.0-3.0 | 3.0-5.0 | 3.2-5.5 | 5.0-8.0 | 10.0-16.0 | 27-35 | 38-50 | 33-47 | 42-53 | |

| 5 | -- | 0.9-1.2 | 1.5-2.0 | 2.0-3.0 | 4.5-6.0 | 9.0-13.0 | 18-26 | 33-40 | 26-35 | 34-43 | |

| 6 | -- | 0.4-0.7 | 1.0-1.8 | 1.4-2.0 | 3.0-4.5 | 7.0-9.0 | 10.0-18.0 | 20-30 | 20-30 | 25-33 | |

| 8 | -- | 0.3-0.5 | 0.5-0.7 | 0.7-1.2 | 1.6-2.2 | 4.5-6.5 | 8.0-10.0 | 18-26 | 16-24 | 20-27 | |

| 10 | -- | -- | 0.3-0.5 | 0.5-1.0 | 0.8-1.2 | 2.4-4.0 | 5.0-7.0 | 10.0-15.0 | 13-18 | 15-20 | |

| 12 | -- | -- | -- | 0.3-0.8 | 0.3-0.5 | 1.5-2.2 | 2.8-4.2 | 5.0-7.0 | 5.4-8.0 | 6.0-8.2 | |

| 14 | -- | -- | -- | -- | 0.3-0.4 | 0.6-1.2 | 1.0-1.8 | 2.4-4.0 | 3.7-6.6 | 4.7-6.8 | |

| 16 | -- | -- | -- | -- | 0.2-0.3 | 0.4-0.6 | 0.8-1.5 | 1.0-1.8 | 2.9-4.5 | 3.2-5.3 | |

| 18 | -- | -- | -- | -- | -- | 0.3-0.5 | 0.6-0.8 | 0.5-1.5 | 1.8-3.2 | 2.3-4.5 | |

| 20 | -- | -- | -- | -- | -- | 0.3-0.4 | 0.4-0.6 | 0.6-1.2 | 1.0-2.1 | 1.8-3.6 | |

| 30 | -- | -- | -- | -- | -- | -- | 0.3-0.4 | 0.4-0.6 | 0.7-1.5 | 1.1-2.8 | |

| 35 | -- | -- | -- | -- | -- | -- | 0.2-0.3 | 0.3-0.4 | 0.5-1.1 | 0.8-2.0 | |

| 40 | -- | -- | -- | -- | -- | -- | 0.2-0.3 | 0.2-0.3 | 0.3-0.7 | 0.6-1.7 | |

| 45 | -- | -- | -- | -- | -- | -- | 0.1-0.2 | 0.1-0.3 | 0.2-0.5 | 0.4-1.0 | |

| 50 | -- | -- | -- | -- | -- | -- | -- | 0.1-0.2 | 0.1-0.3 | 0.3-0.7 | |

| 60 | -- | -- | -- | -- | -- | -- | -- | -- | 0.1-0.2 | 0.2-0.5 | |

| Attention: This table only show the different laser power's max cutting speed, cannot take it as the unique rule for adopting the suitable laser power. Besides, every power's max cutting speed cannot be set as big quantity cutting work. please inquiry our team for the most suitable scheme for your work. |

|||||||||||

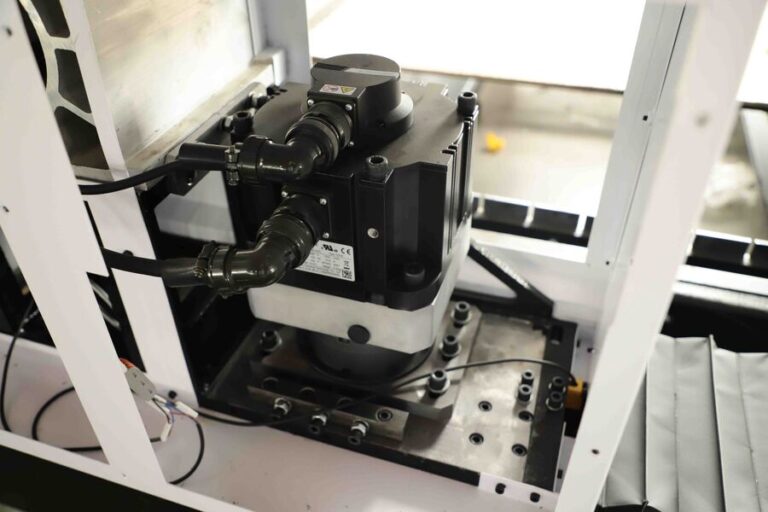

Driving System: Big power servo motor with reducer can not only offer the high power to drive machine working on fast speed, also offer the highest working precisions.

Worktable: Tooth blade worktable can support heavier materials, perfect gap design can used for cutting high complex thin metal sheet cutting for high precision parts manufacture.

Transmission System: Hihg precision grinding rack add imported YYC perfect guild offer best working precision and longer service life, help machine process complex products on best accurancy.

Distribution Box: Professional industrial distribution box, all the electrical parts, and control card.etc be installed well, perfect connect design let all the parts work well together, dust proofing is great, and can also Protect against electromagnetic interference.

Industrial Chiller: Industrial Chiller can offer the constant cool water for the machine working. protect the laser power supply and related parts.

Strong Chain: Used to protect the related wires, water pipe, fiber wire.etc

Auto Lubrication system: A digital auto lubrication system, could lubricate the transmission system automatically timely, more conveniently for working.

Some Optional Auxiliary Parts

Air compressor

Professional fiber laser machine air compressor, used to offer dry clean air for cutting, if the customer’s factory has not related air compressor, could think about getting one with machine together

Transformer

Fiber laser machine working need the 380V 50HZ voltage, if local market has not a suitable voltage, could getting one transformer with machine together, used to transfer other styles’ voltage into 380V 50HZ.

Voltage Stabilizer

Fiber laser machine working need stable voltage, this stabilizer can guarantee the suitable voltage for the machine, avoid the important electric parts be damaged by Fluctuating voltage environment. No matter if your factory voltage is stable or not, recommend all customers will add this parts with machine together,

Applicable Industry

With superior cutting processes and results, our types of equipment, the metal laser cutter, is widely used in many different industries, such as the Advertising Industry, Automobile Manufacture Industry, Gym Equipment Industry, Machine Manufacturing Industry, Medical Equipment Industry, Sanitary Tools Industry, Sheet Metal Cutting Industry, Steel Structure Industry, Steel-Wood Furniture Industry, Tower Industry, and many other areas that required metal cutting solutions.

Aerospace Industry

New Energy Industry

Machine Manufacturing Industry

Sheet Metal Cutting Industry

Gym Equipment Industry

Steel-Wood Furniture Industry

Sanitary Tools Industry

Medical Equipment Industry

Automobile Manufacture Industry

Handicraft Industry