With the rapid development of China’s steel and metal manufacturing industry and the increasing demand for industrial automation, CNC plasma cutting machines are becoming more widely used in the domestic market. This article selects ten representative CNC plasma cutting machine manufacturers in China based on current market data and brand influence. Each company is introduced in terms of brand background, advantageous products, technological R&D, international market presence, after-sales reputation, and positioning characteristics. A comparison table is provided to showcase the core features of each brand, facilitating quick understanding and comparison for readers.

LIGHT CNC Laser

Light CNC Laser

- Corporate Background & Development: LIGHT CNC Laser is an emerging CNC cutting machine manufacturer, known as a "rising star" in the industry. The company adheres to the business philosophy of high cost-effectiveness, personalized customization, and high-quality service, rapidly building a strong reputation in the market. Committed to becoming a "30-year reliable supplier," it has earned customer trust through flexible business models and rapid response capabilities.

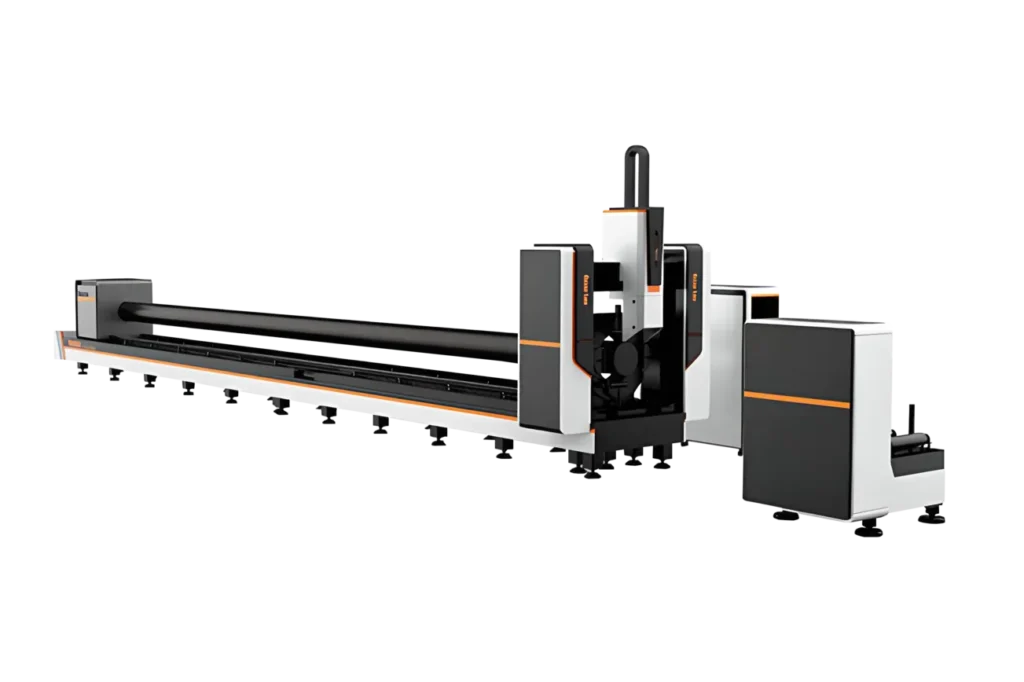

- Main Advantageous Products: Its product line includes high-performance flatbed plasma cutting machines, 8-axis plasma pipe cutting machines, triple-source (laser/plasma/flame) cutting machines, and large gantry plasma/flame cutting machines, covering cutting needs for plates, pipes, and profiles. Products emphasize high cost-effectiveness and customization (e.g., flexible configuration of nozzle quantity and processing paths) for industries like steel structures, boilers, and shipbuilding.

- Technological R&D & Innovation: The company values technological innovation, with a dedicated R&D team continuously optimizing control systems and cutting processes. Despite its short history, it enhances automation and cutting precision through intelligent control and manufacturing tracking technologies.

- Export Capability & International Influence: Primarily focused on the domestic market, LIGHT CNC Laser actively expands overseas. Products are exported to Southeast Asia and the Middle East through exhibitions and sales channels, gradually building a positive international brand image.

- After-Sales Service & Customer Reputation: Commits to rapid after-sales support, including installation, training, and maintenance guidance. Highly praised for customization flexibility and timely technical support.

- Unique Advantage/Positioning: Positions as a "high-cost-effective customized cutting machine" provider. Diversified product lines (flatbed, pipe, triple-source) and controllable solutions appeal strongly to SMEs and individual engineering projects.

LANCNC (Wuhan LANCNC Technology Co., Ltd.)

LANCNC

- Corporate Background & Development: Founded over 10 years ago, LANCNC specializes in R&D, production, and sales of CNC cutting machines. It has become a large-scale, technologically strong manufacturer in Central China, serving over 10,000 customers.

- Main Advantageous Products: Offers gantry, portable, and benchtop CNC cutting machines for steel plates and pipe intersecting lines. Core products include large-format gantry flame/plasma cutters and portable plasma cutters, known for stability and compatibility with various nozzles (laser/plasma/flame).

- Technological R&D & Innovation: Iterates software control systems and mechanical structures to improve cutting precision/speed. Uses advanced servo drives and high-precision guides for reliability.

- Export Capability & International Influence: Products are used domestically and exported to Europe, America, and Southeast Asia. International influence grows through trade and overseas service points.

- After-Sales Service & Customer Reputation: Provides full-cycle services (pre-sales design, on-site installation, training). A domestic service network ensures operational continuity. Well-regarded for attentive service.

- Unique Advantage/Positioning: Markets as a "multi-functional CNC cutting system" provider. High product integration enables plate/pipe cutting in one machine. Offers one-stop solutions for steel structure and pipe manufacturing.

Kasry

KASRY

- Corporate Background & Development: Shandong Kasry Intelligent Equipment Co., Ltd. is a high-tech enterprise integrating R&D, design, production, and sales. It provides holistic solutions for steel structure production lines (cutting, welding, spraying) and has a global sales network.

- Main Advantageous Products: Covers steel structure processing equipment, especially CNC intersecting line cutters, section steel cutters, and H-beam welding lines. Supports plasma/flame cutting for batch processing of special-shaped pipes. Widely used in steel structures, shipbuilding, and bridges.

- Technological R&D & Innovation: Focuses on smart manufacturing R&D, with core intelligent control software and system integration. Explores "Industrial 4.0" applications in cutting robots and automated loading/unloading.

- Export Capability & International Influence: Products sold globally via the "Go Global" strategy. Participates in international exhibitions and sets up overseas offices.

- After-Sales Service & Customer Reputation: Provides full-line delivery, installation, training, and on-site engineering support. Recognized for stable quality and timely response.

- Unique Advantage/Positioning: Positions as an "intelligent steel structure factory solution provider." Integrates cutting, welding, and automation logistics. Offers smart upgrades for large steel enterprises.

Shanghai Hugong (HUGONG)

SHANGHAI HUGONG

- Corporate Background & Development: Founded in 1958, Shanghai Hugong Welding & Cutting Equipment (Group) Co., Ltd. is a large enterprise group integrating R&D, production, and investment. A publicly listed company (SSE: 603701), it has been China’s largest exporter of welding/cutting equipment since 2013, with over 2,000 product models.

- Main Advantageous Products: Complete product lines include welders, inverter cutters, high-power laser cutters, and CNC plasma cutters (e.g., Intec, Flashcut series). Compatible with international plasma power sources for high-speed, high-precision cutting.

- Technological R&D & Innovation: Focuses on digital controls, IoT monitoring platforms, and welding robots. Developed tilt-cutting plasma machines and next-gen laser welders (2020), holding multiple patents.

- Export Capability & International Influence: Exports to 110+ countries/regions. Widely used in large-scale projects across Europe, America, and Asia-Pacific.

- After-Sales Service & Customer Reputation: Global service network and spare parts centers. Praised for reliability and responsive support.

- Unique Advantage/Positioning: Industry leader with three strengths: ① Complete product range; ② Scale and certifications; ③ Digital upgrades (IoT/digital control tech). Targets high-end industrial manufacturing.

Riland (RILAND)

RILAND

- Corporate Background & Development: Shenzhen Riland Industry Co., Ltd. (founded 2003) is a high-tech enterprise listed on the ChiNext (SZSE: 300154). Owns four brands: Riland, Rilon, HighTron, and Tetryl. A leader in China’s welding/cutting sector.

- Main Advantageous Products: Inverter DC arc welders, TIG welders, gas-shielded welders, and inverter air plasma cutters. Portable CNC plasma cutters use self-developed inverter power sources. Applied in pipelines, shipbuilding, and steel structures.

- Technological R&D & Innovation: Emphasizes innovation (founder developed China’s first inverter arc welder in 1987). Holds 180+ patents (27 inventions). Advances digital/lightweight tech and 100kHz high-frequency inverter cutting.

- Export Capability & International Influence: Exports globally. Agents/service points in Europe, America, and the Middle East.

- After-Sales Service & Customer Reputation: 24/7 support with domestic/international service centers. Reliable performance in large projects.

- Unique Advantage/Positioning: "Technology-driven enterprise" with leading inverter plasma tech. Four brands cover diverse segments, offering full solutions from basic to automated cutting.

Jasic (JASIC)

JASIC

- Corporate Background & Development: Shenzhen Jasic Technology Co., Ltd. (founded 2005) is a high-tech listed enterprise (SZSE: 300139). Operates in 80+ countries with 260 patents and 200+ R&D staff.

- Main Advantageous Products: Inverter DC welders, semi-auto welders, TIG welders, and inverter air plasma cutters. Digital-controlled plasma power sources enable high-precision cutting. Used in shipbuilding, petrochemicals, and bridges.

- Technological R&D & Innovation: Invests heavily in R&D, with overseas centers (Italy, USA) and a Shenzhen HQ. Focuses on digital control and smart manufacturing. Participates in national standards development.

- Export Capability & International Influence: Sells to 80+ countries. Grows brand influence via specialized inverter tech and solutions.

- After-Sales Service & Customer Reputation: Comprehensive domestic/international service network. Enhances efficiency through training and optimization.

- Unique Advantage/Positioning: "Integrated welding/cutting solution provider." Competitiveness driven by innovation and R&D, especially in digital welding/cutting.

Aotai (AOTAI)

AOTAI

- Corporate Background & Development: Shandong Aotai Electric Co., Ltd. (founded 1993) is a global industrial welding/cutting equipment manufacturer and national high-tech enterprise. Leads in inverter welding tech and welding robot systems.

- Main Advantageous Products: Industrial inverter welders, welding robots, automated welding systems, and CNC cutting equipment. High-performance plasma cutting power sources suit specialized vehicles and steel structures.

- Technological R&D & Innovation: Maintains R&D platforms (e.g., automated welding labs, IoT cloud platforms). Advances welding robot intelligence and cloud systems.

- Export Capability & International Influence: Exports to 60+ countries. Partners with large overseas projects.

- After-Sales Service & Customer Reputation: Global service network with localized support. Praised for user-friendly operation and low maintenance.

- Unique Advantage/Positioning: "Industrial welding/cutting & automation solution provider." Leverages deep inverter tech expertise and full product lines (welders, robots, cloud platforms).

Time (TIME)

TIME

- Corporate Background & Development: Beijing Time Technologies Co., Ltd. (founded 2001) was jointly established by Time Group, Tsinghua Unisplendour, and Lenovo. Listed on the Shenzhen NEEQ (2006). Covers industries like power, shipbuilding, and chemicals.

- Main Advantageous Products: Multi-series IGBT inverter welders and CNC cutters. Pioneered digital DSP tech in welders (2003). "TD Series" digital welders and large welding equipment complement plasma cutters for full production lines.

- Technological R&D & Innovation: Strong R&D with 40+ sales/service subsidiaries. Focuses on digital controls, robot welding, and IGBT inverters. A Jinan base produces 300K welders annually.

- Export Capability & International Influence: Exports to 40+ countries since 2003. Wins Belt & Road projects.

- After-Sales Service & Customer Reputation: Global service network. Proven reliability in national projects (e.g., Three Gorges Dam).

- Unique Advantage/Positioning: "Comprehensive welding/cutting & automation system expert." Supported by capital/tech partnerships and large-scale production (300K units/year).

Kende (KENDE)

KENDE

- Corporate Background & Development: Zhejiang Kende Mechanical & Electrical Co., Ltd. (founded 2001) is an export-oriented manufacturer. Expands production under "Made in China 2025," with three large bases (200K m² total).

- Main Advantageous Products: Welders, cutters, and chargers for household/industrial use. Includes inverter DC welders, AC TIG welders, and portable plasma cutters. Ensures precision/stability via mature inverter tech.

- Technological R&D & Innovation: Aims to lead global welding equipment. Upgrades products with higher-frequency inverters and digital controls.

- Export Capability & International Influence: Exports to Southeast Asia, Europe, and the Middle East. Builds global networks via exhibitions.

- After-Sales Service & Customer Reputation: Worldwide sales/service support. Low failure rate and fast logistics.

- Unique Advantage/Positioning: Core strengths: mass production and lean technology. Three bases ensure supply/quality stability. Aims to be a globally recognized manufacturer.

Tayor (TAYOR)

TAYOR

- Corporate Background & Development: Shanghai Tayor Electric Welding Machine Co., Ltd. (founded 1998) is a core subsidiary of Shanghai Tayor Heavy Industry Group. A national "Specialized & Sophisticated" enterprise.

- Main Advantageous Products: Digital gas-shielded welders, DC/AC arc welders, TIG welders, and submerged arc welders. Serves heavy industries (steel structures, shipbuilding). Also provides cutting system solutions.

- Technological R&D & Innovation: Innovates via ISO-certified processes and academic partnerships. Advances inverter/digital welding.

- Export Capability & International Influence: Exports to Belt & Road projects.

- After-Sales Service & Customer Reputation: National sales/service network. Long-term partnerships with steel mills.

- Unique Advantage/Positioning: Professional welding equipment supplier. Relies on parent company resources. Focuses on welding automation/digitization.

Brand Comparison Table

| Brand (Company) | HQ Location | Main Products | Key Advantages | Export Market & Influence |

|---|---|---|---|---|

| LIGHT CNC Laser | China (Self-R&D) | Plasma plate/pipe cutters, triple-source cutters | High cost-effectiveness, rapid response | Expanding in Southeast Asia, Middle East |

| LANCNC (Wuhan LANCNC) | Wuhan, Hubei | Gantry/portable/benchtop CNC flame/plasma cutters | Multi-functional solutions, Central China leader | 10K+ domestic clients; exports to EU, Southeast Asia |

| Kasry | Dezhou, Shandong | Intersecting line cutters, section steel cutters, H-beam lines | Smart steel structure systems, factory solutions | Global sales network |

| Shanghai Hugong (HUGONG) | Shanghai | CNC plasma/laser cutters, welders | Complete product lines; 110+ countries | 110+ countries; top exporter |

| Riland (RILAND) | Shenzhen, Guangdong | Inverter welders, plasma cutters | Tech innovation (high-frequency inverter) | Global sales; petrochemicals, shipbuilding |

| Jasic (JASIC) | Shenzhen, Guangdong | Inverter welders, plasma cutters | Integrated solutions; 260+ patents | 80+ countries; growing influence |

| Aotai (AOTAI) | Shandong | Industrial welders, welding robots, CNC cutters | Deep tech expertise, reliability | 60+ countries; high global recognition |

| Time (TIME) | Beijing | IGBT inverter welders, large welders, CNC cutters | Comprehensive equipment; mass production | 40+ countries; international projects |

| Kende (KENDE) | Zhejiang | Welders, cutters, chargers | Mass production, lean processes | Expanding in Asia, Americas |

| Tayor (TAYOR) | Shanghai | Digital TIG welders, arc welders | Welding-focused; participates in standards | Belt & Road projects; exports |

Table integrates public data and market feedback. Manufacturers differentiate by product lines, tech features, and positioning: Hugong and Time excel in global reach; Riland, Jasic, and Aotai lead inverter innovation; Kasry and LANCNC specialize in steel cutting automation; LIGHT CNC Laser competes via customization and cost-effectiveness.

References

- CNC Cutting Machine Manufacturer – Wuhan LANCNC Technology

https://m.11467.com/product/d9058785.htm - Ibid.

- Kasry H-Beam Plasma Cutting Robot Kr-Xh1000

https://kastycnc.en.made-in-china.com/product/YXkQzJOKarUD/China-Kassy-H-Beam-Plasma-Cutting-Robot-Kr-Xh1000.html - Ibid.

5–25. 2023 Top Ten Plasma Cutter Brands Ranking Report

https://m.chinabgao.com/top/brand/70644.html

6–8. HUGONG CUTTING ABOUT US

https://www.hugongcutting.com/about