High-Performance Fiber Laser Cutting Machines for Versatile Applications

What Kind Of Laser Cutting Machine We Can Offer?

At Jinan Light CNC Laser Equipment Co., Ltd., we offer a wide range of fiber laser cutting machines designed to cater to the diverse needs of various industries. Whether you’re in metal fabrication, furniture manufacturing, advertising, or any other industry requiring precise metal cutting, we have the perfect solution for you. We offer a variety of cutting machines with different models and configurations, such as CNC laser cutters and tube laser cutting machines. This guarantees that, regardless of the material or the complexity of your project, you’ll always find the suitable equipment to accomplish the exact working requirement. From cutting intricate patterns in thin sheets to handling heavy-duty pipe and tube processing, our machines are built for efficiency, precision, and reliability. Whether you’re looking for an entry-level machine or a high-powered system for large-scale production, we have the right product to meet your specific needs. Whatever your metal cutting requirements may be, we are here to provide tailored solutions that exceed expectations. Explore our diverse lineup today!

Explore Our Range of Fiber Laser Cutting Machines

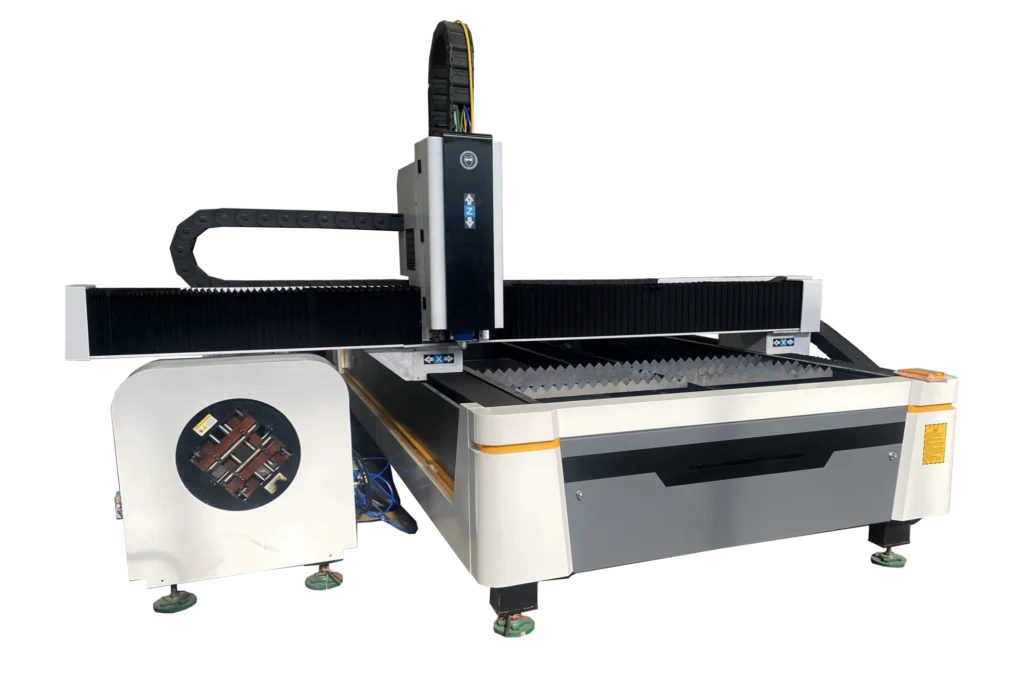

Fiber Laser Cutting Machine

Fiber laser cutting machines are high-precision and fine processing equipment for various industries, the laser power are options from 1kW to 60kW according to materials thickness and working efficiency. With advancements in technology and reduced costs, the laser cutting machine price has become more competitive, making these laser metal cutting machines highly cost-effective.

Affordable High-Precision 3015 Industrial Fiber Laser Cutting Machine

Industrial Fiber Laser Cutting Machine, a top-selling laser machine designed for flat precise metal cutting. 1kw-60kw are optional.

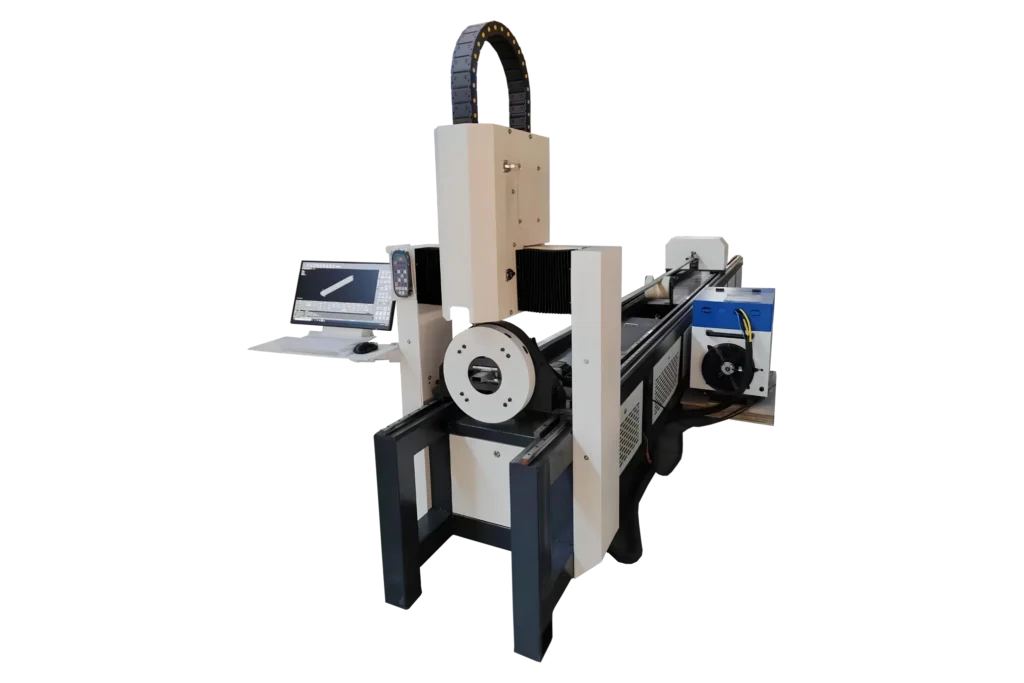

Versatile Tube and Plate Laser Cutting Machine | Advanced Metal Cutting Solution

Tube and plate laser cutting machine, designed for both metal sheet and tube cutting. Combining flatbed cutting with a rotating axis, this versatile machine enhances cutting efficiency and offers a cost-effective solution

High-Efficiency Fiber Laser Metal Cutting Machine | Laser Cutter with Exchange Table

Fiber laser metal cutting machine with an exchange table, designed for seamless material handling during operation. Perfect for large-scale and continuous processing, this machine significantly boosts efficiency

High-Efficiency Coil Fed Laser Cutting Machine | Integrated Coil Laser Cutter

Coil fed laser cutting machine, designed for high-volume sheet metal and ductwork production. This integrated system handles uncoiling, leveling, cutting, and stacking in one machine. Explore specs, images, and more.

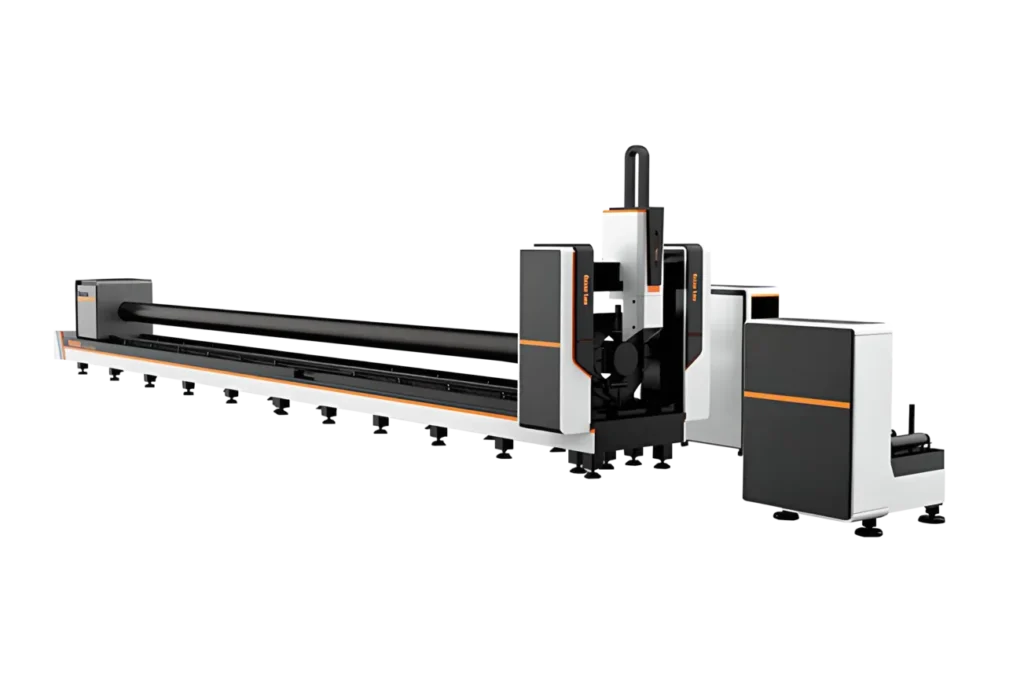

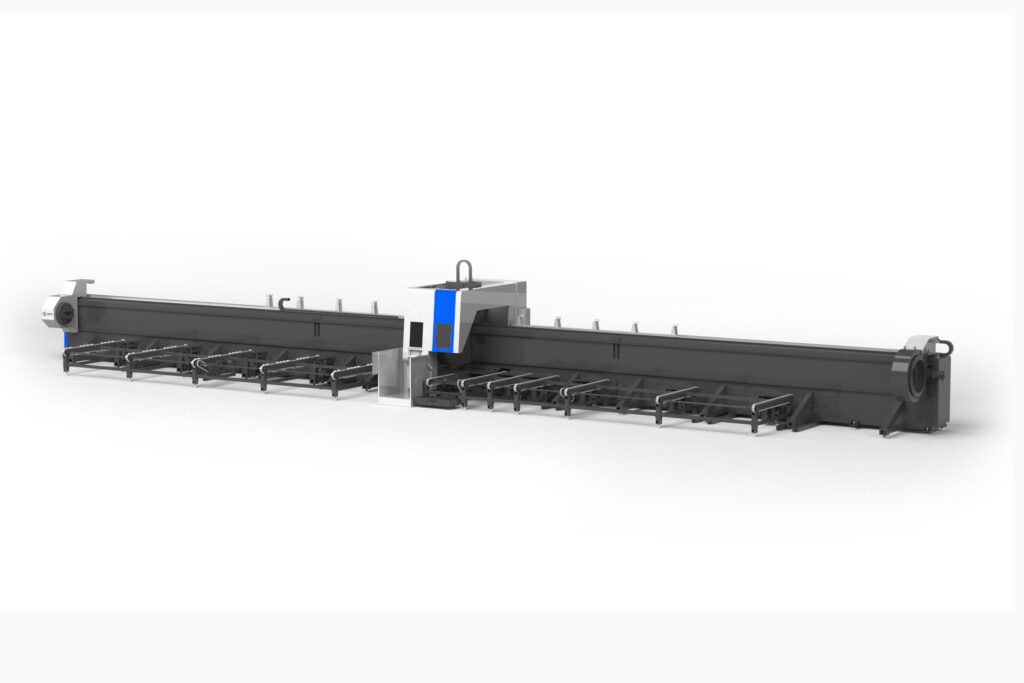

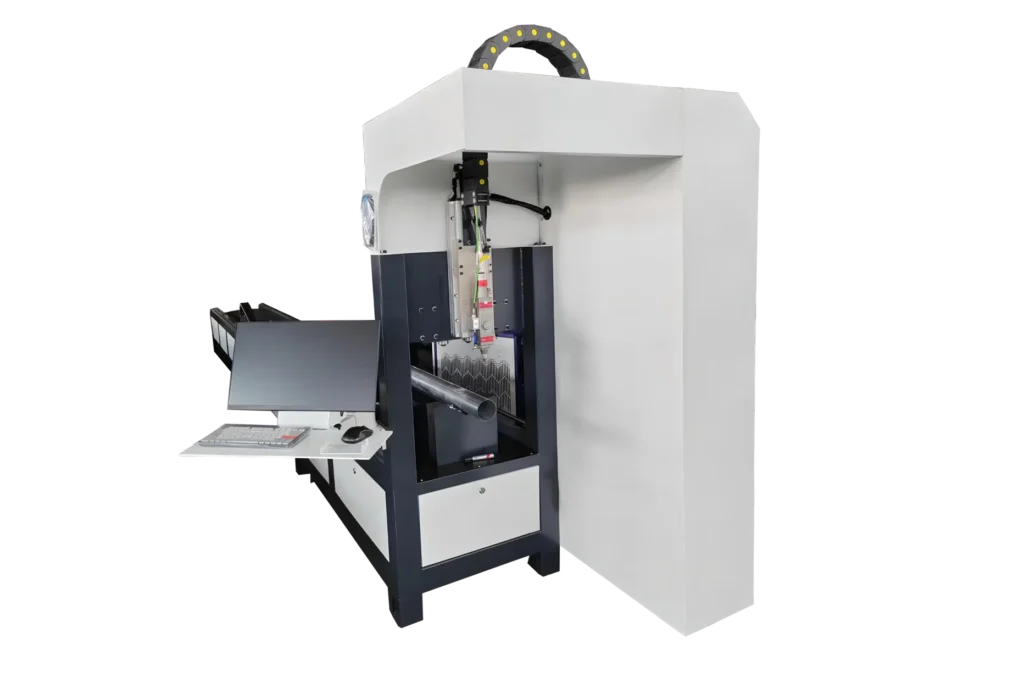

CNC Laser Tube Cutting Machine

CNC Tube Cutting Machines are specialized equipment in the fiber laser cutter and plasma cutter categories, designed for tube and pipe processing. Available in various models, they handle round, square, H-shaped, and custom-shaped tubes with high precision. Depending on material size and efficiency needs, you’ll find a range of options to suit your requirements. Explore competitive tube laser cutting machine prices and advanced fiber laser tube cutting machines to CNC plasma tube cutters tailored to your projects.

High-Efficiency CNC Laser Pipe Cutting Machine | Smooth and Fast Fiber Laser Cutter

Laser pipe cutting machine, designed for smooth and fast cutting of round pipes. Easy to operate without drawing, featuring an electric chuck for automatic clamping

Contact Us to Get A Quotation

Applicable Industry

With superior cutting processes and results, our types of equipment, the cnc laser cutting machine, tube laser cutting machine. Have a perfect cutting effect on cut various carbon steel, stainless steel, brass, aluminum, galvanized steel.etc. Offer great cutting functions on sheet metal, square tube, round pipe, H-type, I-stype, U-bar, giured steel.etc. So widely used in many different industries, such as Advertising Industry, Automobile Manufacture Industry, Gym Equipment Industry, Machine Manufacturing Industry, Medical Equipment Industry, Sanitary Tools Industry, Sheet Metal Cutting Industry, Steel Structure Industry, Steel-Wood Furniture Industry, Tower Industry, and many other areas that required metal cutting solutions.

Tower Industry

Steel Structure Industry

Machine Manufacturing Industry

Sheet Metal Cutting Industry

Gym Equipment Industry

Steel-Wood Furniture Industry

Sanitary Tools Industry

Medical Equipment Industry

Automobile Manufacture Industry

Advertising Industry

CNC Laser Cutting Machine Videos

6kw fiber laser machine cut 12mm stainless steel

industrial laser cutting machine cut 6mm metal gear

3 in 1 laser plasma flame cnc cutting machine

12kw laser cutting machine cut thicker metal sheet

3kw fiber laser cutting machine cut sheet on high speed

tube laser cutting machine cut 8mm thickness 3mm diameter hose

5 Aixs Laser tube Cutting Machine cut Bevel

2 Chucks Laser tube pipe Cutting machine with auto loading system

5 Axis Tube Laser Cutting Machine Cut Channel Steel, Angle Steel, Round Pipe

OEM Service

We can offer OEM service.

For the end user, we can design and offer the new styles of fiber laser cutting machine according to your exact materials’ styles, thickness, size and exact processing requirement, even the factory workspace, investment plan.etc.

For distributors, brand or importers, we can offer customized designs, including machine models, accessories, and unique working functions to meet the different market requirement.

No matter what’s your requirement for the new models of machine, our team will offer the strongest support to try to help you realize the dream.

How to Adopt Suitable Laser Power?

When choosing the laser power, we generally choose the right power according to the following three points.

1.Cutting effect

Take the most commonly cutting stainless steel and carbon steel, when cutting stainless steel, the higher the power, the faster the speed, the greater the cutting thickness. In the cutting of carbon steel, you can use oxygen-assisted or air-assisted, in the use of oxygen-assisted cutting, you can produce four styles of cutting surface.

One is a bright black surface, this effect is the best, the cutting surface is smooth and oily; the remaining three are grey surface.

A choice of large nozzles to cut the surface of grey surface, the surface has a layer of oxidised skin.

A choice of small nozzles to cut , the effect is similar to plasma flame cutting.

The last one is the grey surface produced by negative-focus cutting, the upper part of this grey surface has more obvious scars, but the cutting speed is greater than the above three.

Generally speaking, in the cutting of medium-thick plates, which is more than 16mm thickness, the use of negative-focus cutting is more (please refer to the following table). In the case of the same wattage cutting to reach the black surface of the speed will be lower than the speed of the grey side, the grey surface of the cutting speed is great, and the cutting efficiency is higher.

2.Maximum cutting thickness

Combined with the desired cutting effect and the maximum thickness to be cut, to choose the appropriate laser power. (Refer to the following table).

According to the carbon steel often processed plate thickness, oxygen cutting black surface effect is good; air cutting, if the use of high-quality cutting limit thickness within the processing effect is better. For example, oxygen cutting 10mm carbon steel, it is recommended to choose 6KW, air cutting 10mm carbon steel, it is recommended that 12kw.

According to the thickness of stainless steel plate, the greater the power, the faster the cutting speed, the thicker the cutting thickness, but subject to the mechanical accuracy of the machine tool constraints, if you often cut thin plates, it is recommended that the speed control within 30m/min; if you cut a thick plate, the greater the power, the better the effect, and at the same time refer to the cutting speed for selection. For example, if you often cut plates below 5mm, to achieve high cutting efficiency, you can choose 6kw.

| Different Cutting Effect&Thickness Recommend Choice | |||||

|---|---|---|---|---|---|

| Laser Power | Carbon Steel | Stasinles Steel | |||

| Black Surface Max Thickness (mm) | Oxygen-Assit Max Cut Thickness (mm) | Air-Assit perfect cut effect Max thickness (mm) | 30m/min Thickness (mm) | Max Cut Thickness (mm) |

|

| 3000W | 8 | 20 | 5 | 1 | 12 |

| 6000W | 14 | 25 | 8 | 2 | 30 |

| 12000W | 25 | 35 | 12 | 5 | 40 |

| 20000W | 30 | 40 | 16 | 6 | 50 |

| 30000W | 40 | 60 | 30 | 8 | 70 |

3.When to choose 12KW, 20KW 30KW or Higher Power?

Generally speaking, there are two cases to choose 12KW, 20KW, 30KW or higher power.

The first is when you need to air cut the plate without the help of oxygen or nitrogen and need to save money. When air cutting plates, higher power lasers are needed to achieve higher cutting efficiency, and 10,000W lasers are the best choice.

The second is when there is a need to cut plates of greater thickness. High-power lasers have a significant advantage is to be able to cut the thickness of the plate is relatively large, in general, in the cutting of medium-thickness plates (thickness greater than 16mm), will choose the 10,000-watt laser. But if cutting thin plates, it is not suitable. Because from 6KW upgraded to 12KW, 20KW, 30KW, cutting thin plate speed will not have too obvious increase, subject to mechanical precision, the actual working speed often does not reach the theoretical maximum, but the price of the machine and processing costs will increase a lot.

| Different Laser Powers' Cutting Function Table | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Laser Power | 1.5KW | 2KW | 3KW | 4KW | 6KW | 12KW | 20KW | 30KW | 40KW | 60KW | |

| Materials | Thickness(mm) | Speed (m/min) | |||||||||

| Carbon Steel (O2) | 1 | 15-20 | 24-30 | 30-40 | 33-43 | 35-44 | 60-75 | 65-85 | 70-90 | 80-95 | 90-100 |

| 2 | 4.0-5.0 | 4.7-6.5 | 4.8-7.5 | 15-25 | 20-28 | 28-40 | 50-75 | 60-80 | 70-80 | 78-88 | |

| 3 | 3.0-4.0 | 3.0-4.8 | 3.3-5.0 | 7.0-12 | 13-17 | 18-30 | 45-65 | 50-75 | 55-80 | 65-90 | |

| 4 | 2.3-2.8 | 2.8-3.5 | 3.0-4.2 | 3.0-4.0 | 3.0-4.5 | 3.5-5.5 | 5-7.0 | 6.5-10 | 40-70 | 50-80 | |

| 5 | 1.8-2.3 | 2.2-3.0 | 2.6-3.5 | 2.7-3.6 | 3.0-4.2 | 3.3-4.8 | 5.3-6.5 | 6.5-9.0 | 30-55 | 42-65 | |

| 6 | 1.6-2.0 | 1.8-2.6 | 2.3-3.2 | 2.5-3.4 | 2.5-3.5 | 3.0-4.2 | 4.0-5.5 | 6.0-9.0 | 20-25 | 35-45 | |

| 8 | 1.2-1.5 | 1.2-1.8 | 1.8-2.6 | 2.0-3.0 | 2.2-3.2 | 2.5-3.5 | 3.5-5.0 | 5.5-8.5 | 17-20 | 30-40 | |

| 10 | 0.6-0.8 | 1.1-1.3 | 1.2-2.0 | 1.5-2.4 | 1.8-2.5 | 2.2-2.7 | 3.5-4.7 | 5.0-8.0 | 15-20 | 20-25 | |

| 12 | 0.5-0.6 | 0.9-1.2 | 1.0-1.6 | 1.2-2.8 | 1.2-2.0 | 1.2-2.1 | 2.0-4.0 | 4.0-7.3 | 9.0-12 | 10-14.5 | |

| 14 | -- | 0.7-0.8 | 0.9-1.4 | 0.9-1.2 | 1.2-1.8 | 1.7-1.9 | 1.7-3.0 | 3.7-6.0 | 8.0-10.5 | 9.0-13.5 | |

| 18 | -- | 0.4-0.6 | 0.6-0.8 | 0.6-0.9 | 0.6-0.9 | 1.0-1.8 | 1.5-2.3 | 3.3-5.0 | 6.5-9.5 | 7.5-11.5 | |

| 20 | -- | 0.2-0.4 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.6-1.5 | 1.5-2.3 | 2.4-4.0 | 6.0-8.5 | 6.8-10.2 | |

| 25 | -- | -- | 0.2-0.5 | 0.3-0.55 | 0.3-0.55 | 0.5-1.1 | 1.0-1.5 | 2.0-3.5 | 5.1-8.3 | 6.1-9.5 | |

| 30 | -- | -- | -- | -- | 0.2-0.5 | 0.3-0.9 | 0.8-1.1 | 1.5-2.5 | 3.0-4.5 | 5.0-8.5 | |

| 40 | -- | -- | -- | -- | -- | 0.2-0.6 | 0.6-1.0 | 1.2-2.0 | 2.5-3.0 | 3.8-6.0 | |

| 50 | -- | -- | -- | -- | -- | -- | 0.5-0.8 | 0.8-1.7 | 2.0-3.0 | 3.2-5.0 | |

| 60 | -- | -- | -- | -- | -- | -- | 0.4-0.7 | 0.5-1.5 | 1.0-1.5 | 2.1-4.5 | |

| 70 | -- | -- | -- | -- | -- | -- | 0.3-0.5 | 0.4-0.7 | 0.6-1.3 | 1.5-2.5 | |

| 80 | -- | -- | -- | -- | -- | -- | -- | 0.2-0.5 | 0.3-1.0 | 0.6-1.5 | |

| 90 | -- | -- | -- | -- | -- | -- | -- | -- | 0.2-0.4 | 0.4-1.0 | |

| Stainless Steel (N2) | 1 | 20-25 | 24-36 | 30-35 | 32-45 | 45-52 | 60-72 | 72-100 | 80-105 | 85-110 | 95-130 |

| 2 | 8.0-10.0 | 6.0-10.0 | 13-21 | 16-28 | 20-33 | 35-45 | 45-70 | 55-80 | 75-98 | 90-118 | |

| 3 | 4.5-5.5 | 2.2-3.5 | 6.0-10 | 7.0-1.5 | 15-22 | 20-30 | 38-50 | 45-70 | 55-80 | 85-100 | |

| 4 | 3-3.5 | 1.2-1.6 | 4.0-6.0 | 5.0-8.0 | 10.0-15.0 | 15-22 | 25-35 | 38-65 | 47-70 | 68-92 | |

| 5 | 1.5-2.0 | 0.6-0.75 | 3.0-5.0 | 3.5-5.0 | 8.0-12 | 10-18 | 20-30 | 30-63 | 40-66 | 55-83 | |

| 6 | 0.7-0.9 | 0.6-0.75 | 2.0-4.0 | 2.5-4.5 | 4.8-8.0 | 8-12 | 15.0-25.0 | 25-53 | 35-60 | 43-60 | |

| 8 | -- | 0.5-0.6 | 1.5-2.0 | 1.2-2.0 | 3.0-4.0 | 5.0-7.5 | 8.0-12.0 | 20-45 | 30-53 | 35-53 | |

| 10 | -- | 0.4-0.5 | 0.6-0.8 | 0.8-1.2 | 1.6-2.5 | 3.0-7.0 | 6.0-10.0 | 20-32 | 25-40 | 30-50 | |

| 12 | -- | -- | 0.4-0.6 | 0.5-0.8 | 0.8-1.5 | 2.5-3.9 | 4.0-6.0 | 15-25 | 18-30 | 20-30 | |

| 14 | -- | -- | -- | 0.4-0.6 | 0.6-0.8 | 1.8-2.8 | 3.5-6.0 | 13-20 | 15-25 | 17-27 | |

| 18 | -- | -- | -- | -- | 0.4-0.6 | 1.2-1.8 | 1.2-2.2 | 8.0-12.0 | 10.0-13.0 | 13-18 | |

| 20 | -- | -- | -- | -- | 0.3-0.5 | 0.9-1.5 | 1.3-1.8 | 6.0-8.0 | 7.3-10 | 8.0-13 | |

| 25 | -- | -- | -- | -- | 0.2-0.4 | 0.6-0.7 | 0.6-1.2 | 4.0-5.5 | 5.0-7.5 | 6.0-9.1 | |

| 30 | -- | -- | -- | -- | 0.2-0.4 | 0.3-0.6 | 0.5-1.0 | 2.5-3.9 | 3.5-4.9 | 4.0-5.8 | |

| 40 | -- | -- | -- | -- | -- | 0.3-0.5 | 0.3-0.6 | 1.8-2.8 | 2.8-4.0 | 3.6-4.9 | |

| 50 | -- | -- | -- | -- | -- | 0.3-0.4 | 0.2-0.5 | 1.3-1.8 | 1.3-2.8 | 2.3-3.3 | |

| 60 | -- | -- | -- | -- | -- | 0.2-0.3 | 0.2-0.4 | 0.5-0.8 | 0.9-1.8 | 1.9-2.3 | |

| 70 | -- | -- | -- | -- | -- | -- | 0.2-0.35 | 0.5-1.0 | 0.6-1.0 | 1.2-1.7 | |

| 80 | -- | -- | -- | -- | -- | -- | -- | 0.2-0.4 | 0.5-0.8 | 0.5-1.0 | |

| 90 | -- | -- | -- | -- | -- | -- | -- | -- | 0.2-0.3 | 0.2-0.7 | |

| Aluminum (N2) | 1 | 12.0-16.0 | 15-20 | 25-38 | 35-45 | 42-55 | 45-50 | 55-65 | 60-70 | 75-95 | 75-110 |

| 2 | 4.0-5.0 | 7.0-10.0 | 10.0-18.0 | 13-24 | 20-40 | 30-35 | 33-45 | 55-65 | 70-85 | 84-98 | |

| 3 | 1.5-2.5 | 4.0-6.0 | 6.5-8.0 | 7.0-13 | 15-25 | 20-25 | 25-35 | 40-55 | 60-77 | 73-90 | |

| 4 | 1-1.3 | 2.0-3.0 | 3.5-5.0 | 4.0-5.5 | 9.5-12 | 18-20 | 15-25 | 38-50 | 53-67 | 63-83 | |

| 5 | -- | 1.2-1.8 | 2.5-3.5 | 3.0-4.5 | 5.0-8.0 | 14-16 | 13-20 | 35-45 | 43-60 | 52-77 | |

| 6 | -- | 0.7-1.0 | 1.5-2.5 | 2.0-3.5 | 3.8-5.0 | 10-12 | 9.0-12 | 25-35 | 36-58 | 47-68 | |

| 8 | -- | 0.6-0.8 | 0.7-1.0 | 0.9-1.6 | 2.0-2.5 | 6.0-8.0 | 4.5-6.5 | 20-30 | 28-48 | 32-57 | |

| 10 | -- | -- | 0.4-0.7 | 0.6-1.2 | 1.0-1.5 | 4.0-6.0 | 2.8-4.0 | 15-24 | 20-35 | 25-45 | |

| 12 | -- | -- | -- | 0.4-0.6 | 0.8-1.0 | 2.0-3.0 | 1.9-2.5 | 13-20 | 18-30 | 20-37 | |

| 16 | -- | -- | -- | -- | 0.5-0.8 | 1.3-2 | 1.5-2.0 | 10.0-15.0 | 13-27 | 16-30 | |

| 20 | -- | -- | -- | -- | -- | 0.8-1.2 | 0.8-1.2 | 9.0-12 | 11-20 | 13-28 | |

| 30 | -- | -- | -- | -- | -- | 0.3-0.8 | 0.3-0.7 | 6.0-10.0 | 9.3-16.7 | 11.2-22.3 | |

| 40 | -- | -- | -- | -- | -- | 0.2-0.4 | 0.3-0.5 | 4.0-6.0 | 7.7-13.7 | 8.2-18.3 | |

| 50 | -- | -- | -- | -- | -- | 0.1-0.2 | 0.2-0.4 | 2.0-3.0 | 5.8-10.7 | 6.8-15.7 | |

| 60 | -- | -- | -- | -- | -- | -- | 0.2-0.3 | 1.3-1.8 | 3.8-8.3 | 4.3-10.5 | |

| 70 | -- | -- | -- | -- | -- | -- | 0.1-0.2 | 0.3-0.8 | 2.5-6.7 | 2.3-7.2 | |

| 80 | -- | -- | -- | -- | -- | -- | -- | 0.2-0.3 | 1.0-3.7 | 0.9-3.1 | |

| Brass (N2) | 1 | 9.0-12.0 | 10.0-16.0 | 20-35 | 25-35 | 35-45 | 50-60 | 75-85 | 78-88 | 80-90 | 85-95 |

| 2 | 4.0-5.0 | 5.0-6.0 | 6.0-10 | 8.0-12 | 20-30 | 33-40 | 40-55 | 55-65 | 68-77 | 72-87 | |

| 3 | 1.5-2.0 | 2.5-4.0 | 4.0-6.0 | 5.0-8.0 | 12.0-18.0 | 15-23 | 32-50 | 40-55 | 45-58 | 50-60 | |

| 4 | -- | 2.0-3.0 | 3.0-5.0 | 3.2-5.5 | 5.0-8.0 | 10.0-16.0 | 27-35 | 38-50 | 33-47 | 42-53 | |

| 5 | -- | 0.9-1.2 | 1.5-2.0 | 2.0-3.0 | 4.5-6.0 | 9.0-13.0 | 18-26 | 33-40 | 26-35 | 34-43 | |

| 6 | -- | 0.4-0.7 | 1.0-1.8 | 1.4-2.0 | 3.0-4.5 | 7.0-9.0 | 10.0-18.0 | 20-30 | 20-30 | 25-33 | |

| 8 | -- | 0.3-0.5 | 0.5-0.7 | 0.7-1.2 | 1.6-2.2 | 4.5-6.5 | 8.0-10.0 | 18-26 | 16-24 | 20-27 | |

| 10 | -- | -- | 0.3-0.5 | 0.5-1.0 | 0.8-1.2 | 2.4-4.0 | 5.0-7.0 | 10.0-15.0 | 13-18 | 15-20 | |

| 12 | -- | -- | -- | 0.3-0.8 | 0.3-0.5 | 1.5-2.2 | 2.8-4.2 | 5.0-7.0 | 5.4-8.0 | 6.0-8.2 | |

| 14 | -- | -- | -- | -- | 0.3-0.4 | 0.6-1.2 | 1.0-1.8 | 2.4-4.0 | 3.7-6.6 | 4.7-6.8 | |

| 16 | -- | -- | -- | -- | 0.2-0.3 | 0.4-0.6 | 0.8-1.5 | 1.0-1.8 | 2.9-4.5 | 3.2-5.3 | |

| 18 | -- | -- | -- | -- | -- | 0.3-0.5 | 0.6-0.8 | 0.5-1.5 | 1.8-3.2 | 2.3-4.5 | |

| 20 | -- | -- | -- | -- | -- | 0.3-0.4 | 0.4-0.6 | 0.6-1.2 | 1.0-2.1 | 1.8-3.6 | |

| 30 | -- | -- | -- | -- | -- | -- | 0.3-0.4 | 0.4-0.6 | 0.7-1.5 | 1.1-2.8 | |

| 35 | -- | -- | -- | -- | -- | -- | 0.2-0.3 | 0.3-0.4 | 0.5-1.1 | 0.8-2.0 | |

| 40 | -- | -- | -- | -- | -- | -- | 0.2-0.3 | 0.2-0.3 | 0.3-0.7 | 0.6-1.7 | |

| 45 | -- | -- | -- | -- | -- | -- | 0.1-0.2 | 0.1-0.3 | 0.2-0.5 | 0.4-1.0 | |

| 50 | -- | -- | -- | -- | -- | -- | -- | 0.1-0.2 | 0.1-0.3 | 0.3-0.7 | |

| 60 | -- | -- | -- | -- | -- | -- | -- | -- | 0.1-0.2 | 0.2-0.5 | |

| Attention: This table only show the different laser power's max cutting speed, cannot take it as the unique rule for adopting the suitable laser power. Besides, every power's max cutting speed cannot be set as big quantity cutting work. please inquiry our team for the most suitable scheme for your work. |

|||||||||||

Contact Us to Get A Quotation

How to adopt the suitable Type of Fiber laser cutting machine?

There are many different types of fiber laser machine, which can be roughly divided into three types: bed-type, bed-type with exchange platform and Ground-rail large format cutting machine. Each type has its own advantages and disadvantages and suitable for the processing field, exactly how to choose the right model? We can choose according to the following characteristics of each type of machine, combined with your own processing needs.

First type: Bed-type all-in-one machine without cover.

Traditional industrial laser cutting machine structure, beam are double-driver, without a large surround cover, table placed on the bed.

Advantages: Better overall rigidity, easy to install, price cheap, is now a mainstream model.

Disadvantages: Poor dust removal, no laser protection; single table’s loading and unloading material efficiency is low, because although the bed can be 6m or even 12m long, but when laser machine working,it’s not suitable to do loading and unloading materials operation in front or behind, because it will make the bed vibration, affecting the laser cutting accuracy. The length of the bed is limited, the longest usually can only do 12m, if too long, bed will be deformed, resulting in cutting accuracy is not up to standard.

Suitable for: processing volume is not very large, and need to do precision processing customers.

Second type: Bed type with exchange working platform

The machine is enclosed by full cover structure, the beam is driven bilaterally, the table is placed on the bed, and it is equipped with an exchange platform.

Advantages: Better rigidity, better dust removal, beautiful appearance, high efficiency of cutting thin plate loading and unloading.

Disadvantages: Limited load-bearing of the exchange platform, not suitable for cutting medium-thick plates. The length of the bed is limited; the installation foundation and technical requirements are high; the cutting state is not suitable for observation, even if there is a camera, it is not as easy to observe the cutting state as the open platform.

Suitable for: customers who have large processing volume and mainly do thin plate (within 12mm) processing.

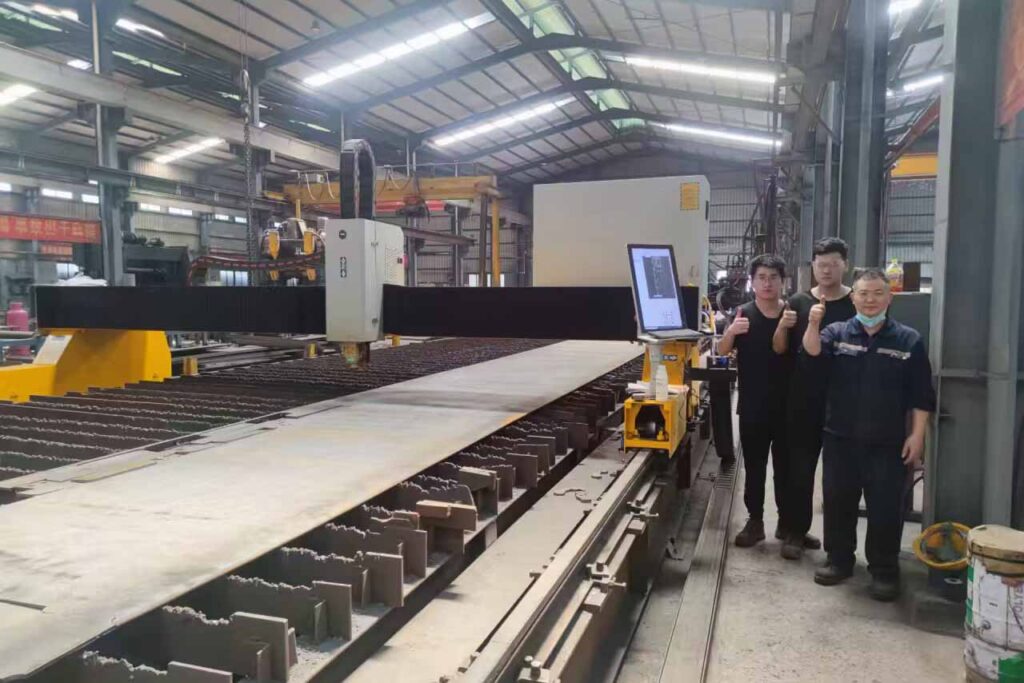

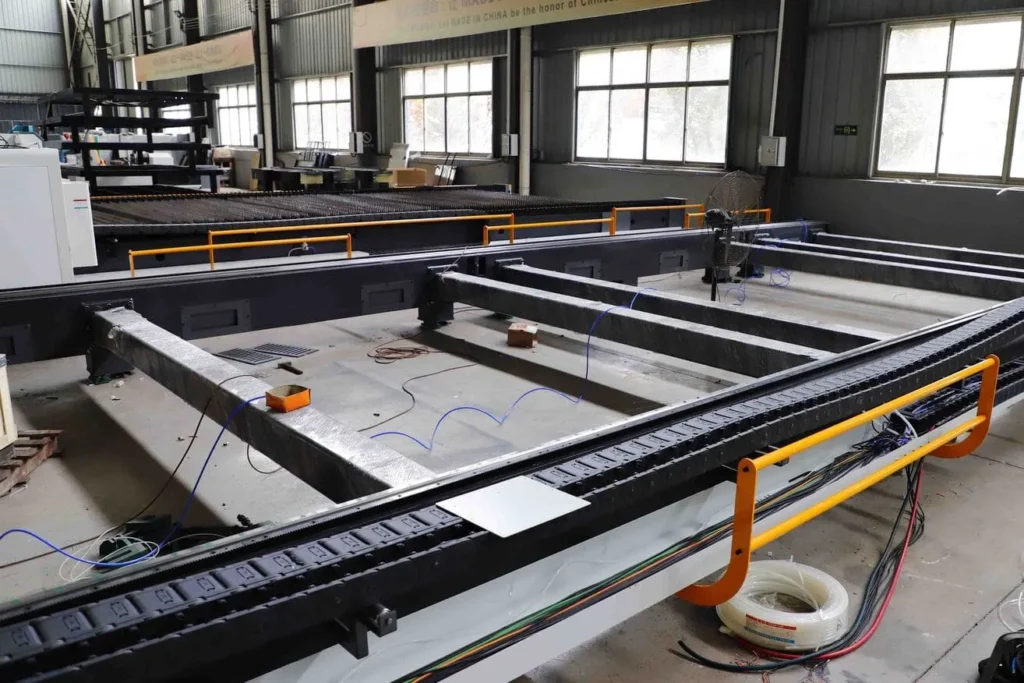

Third Type: Ground-rail type large format cutting machine

Split bed, beam bilateral drive, table top is placed separately. The drive system is separated from the table top, not affected by the load bearing of the table top.

Advantages: no thermal deformation of the bed, good load bearing capacity of the table and can be easily replaced later. Large processing width, in principle, can be extended indefinitely, most models are 3.5m wide, 6m, 12m or even 24m long.

Disadvantages: Cumbersome installation process. Processing accuracy is relatively poor, but can meet the processing plant for the processing of raw materials, if the direct processing of high-precision mechanical components, it is recommended that the first two types. Machine speed is relatively slow, because most of the cutting is thick plate, the actual cutting speed need not be too fast.

Suitable for: Processing large quantities, high demand for processing efficiency, and mainly do the processing of medium-thick plate customers.

How long is the service life of laser cutting machine?

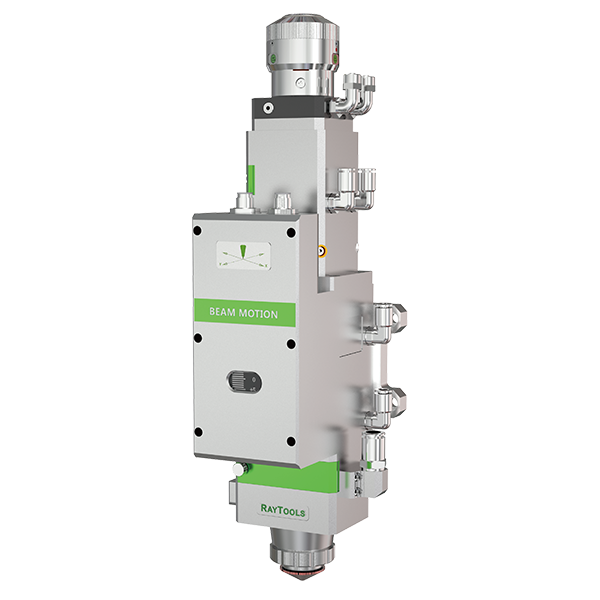

The lifespan of a industrial laser cutting machine is usually determined by the three most important accessories: the fiber laser power supply, the laser head and the Transmission system.

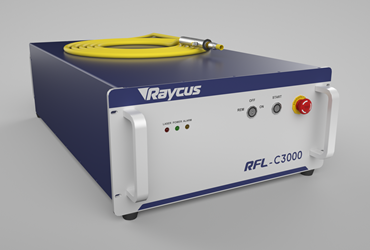

First, the fiber laser power supply. Take the two most common domestic laser Raycus and Maxpower on the market now, the theoretical working time are in 100 000 hours, that is, about 12 years, if work about 10 hours every day, not taking into account other factors, in close to 28-30 years can continue to produce light. Although the power of fiber lasers declines every year as the operating time increases, the annual decline rate is less than 1%. Overall very stable.

Second, the laser head. The laser head is mainly composed of two parts, namely, the external metal hardware structure and the internal lens, the external metal parts as long as it is not suffered a violent impact or man-made destruction, is not damaged. The internal lens is more fragile, but it can continue to work as long as it is replaced. So theoretically speaking, the life of the laser head is unlimited.

Finally, the transmission system of the machine, mainly including bearings, rails and racks, as long as the regular maintenance of its maintenance, lubricating oil, under normal wear and tear 10-15 years of continuous use are no problem.

In addition there is a more important factor than the above three points. Now, the price of high-power fiber laser machine is getting lower and lower, and the overall price of the equipment is also decreasing, for a processing plant with high-volume processing needs or end-users, usually do not wait until the above three accessories to reach the service life of the term, will choose to upgrade the cutting equipment, so in general, the service life of the cutting machine is fully able to meet the needs of customer processing.

How About The Working Cost of Fiber Laser Machine?

Generally speaking, there are three kinds of energy consumption when the fiber laser machine is running, namely, electricity, consumables and gas.

For electricity, it includes the energy consumption of the laser, chiller, bed electronics, dust removal equipment, and gas supply device.

Consumables are mainly the loss of lenses and fiber lasers. There are three main types of gases, namely air cutting, oxygen cutting and nitrogen cutting, and the energy consumption of the three types is different.

Please refer to the following table for specific energy consumption.

| Laser Cutting Machine Working Cost | |||

|---|---|---|---|

| Laser Power | Different Gas-Assisted | ||

| Air-Assisted Cutting Cost (RMB/H) | Oxygen-Assisted Cutting (RMB/H) | Nitrogen-Assisted Cutting (RMB/H) |

|

| 1000W | 26.91 | 20.16 | 214.16 |

| 2000W | 35.58 | 25.28 | 218.58 |

| 3000W | 40.8 | 31.8 | 223.8 |

| 4000W | 42.5 | 35.5 | 225.5 |

| 6000W | 50.6 | 43.6 | 283.6 |

| 12000W | 71.3 | 64.3 | 354.3 |

| 20000W | 101.9 | 94.9 | 384.9 |

| 30000W | 122.9 | 117.9 | 455.9 |

| 40000W | 144.7 | 139.7 | 477.7 |

| Attention: The Electric cost be calculed by 1RMB on 1KW/H.(380V 3pahse industrail electric) | |||

Contact Us to Get A Quotation

What Is the Price&Cost of Fiber Laser Cutting Machine?

When purchasing a CNC laser cutting machine, the total cost includes several key components:

Machine Parts: Includes the machine bed, generator, cutting head, water chiller, gas cylinder, air tank, power supply, air compressor, cooling dryer, filters, exhaust fan, dust remover, and slag extractor.etc

Cutting System & Software: Essential for machine operation.

Shipping Fees: Vary by location and delivery method.

Taxes & Customs: Based on country-specific regulations.

Service & Technical Support: Ongoing maintenance and assistance.

Latest Pricing Overview

Fiber Laser Cutters: The average price for a new fiber laser cutter is around $32,600, down 18% from before $39,800.

Entry-Level Machines: Starting from $14,200 to $32,800 for 1000W-1500W power, ideal for small businesses or beginners.

Professional Systems: Priced from $29,800, with power ranges from 2000W to 6000W, suitable for commercial applications requiring precision.

Industrial Models: Range from $88,000 to over $500,000 for machines with power from 12000W to 60,000W, designed for heavy-duty metal cutting.

Combination Laser Tables: A versatile option starting at $19,800 for cutting materials like metal, wood, acrylic, and more.

Also please check below review price range to pick up your Budget.

| Fiber Laser Cutting Machine Price Range | |||

|---|---|---|---|

| Laser Powers | Minimum Price | Maximum Price | Average Price |

| 1000W | $11,500 | $32,000 | $15,250 |

| 1500W | $13,000 | $34,000 | $17,210 |

| 2000W | $15,000 | $42,000 | $21,320 |

| 3000W | $20,000 | $60,000 | $26,010 |

| 4000W | $36,000 | $70,000 | $45,300 |

| 6000W | $37,000 | $80,000 | $50,100 |

| 12000W | $65,000 | $119,000 | $110,000 |

| 20000W | $105,000 | $300,000 | $165,000 |

| 30000W | $200,000 | $400,000 | $252,300 |

| 40000W | $320,000 | $600,000 | $391,800 |

| 60000W | $500,000 | $1,000,000 | $720,000 |

| Attention: Above price are just for review to help you make budget, the final price will be different according to your favorite machine model. if want to get exact price, please inquiry us. |

|||

How to Choose a cost-effective fiber laser cutting machine?

Generally speaking, the cost performance of a fiber laser machine is determined by the four most important parts, the fiber laser power suppl, the laser head, the control system and the bed, so how to choose a cost-effective fiber machine? We hope that the following description of the four most important parts will help you.

Fiber laser power supply.

Mainly divided into Chinese brands and other imported brands, each with its own advantages and disadvantages, in general, it is recommended to choose the domestic fiber laser. Because although the quality of imported lasers is more stable and the cutting effect is better, the price is much higher than the domestic ones, and it will cost you a huge amount of money when you do maintenance and need to upgrade the power later. Domestic lasers in recent years the development of good, the future indicators and features will slowly improve, the cost-effectiveness of domestic lasers will be much higher than imported lasers.

| Laser Power Supply Style | Brand | Price | Laser Quality | Maintenance costs | Resale Value | Energy consumption | Quality Stability |

|---|---|---|---|---|---|---|---|

| Chinese Brand | Raycus, Maxpower, CPT, RECI.etc | Low | Common | Low | Low | High | Common |

| Imported Brand | IPG, Trumpf, nLIGHT.etc | Hihg | Good | High | High | Low | High |

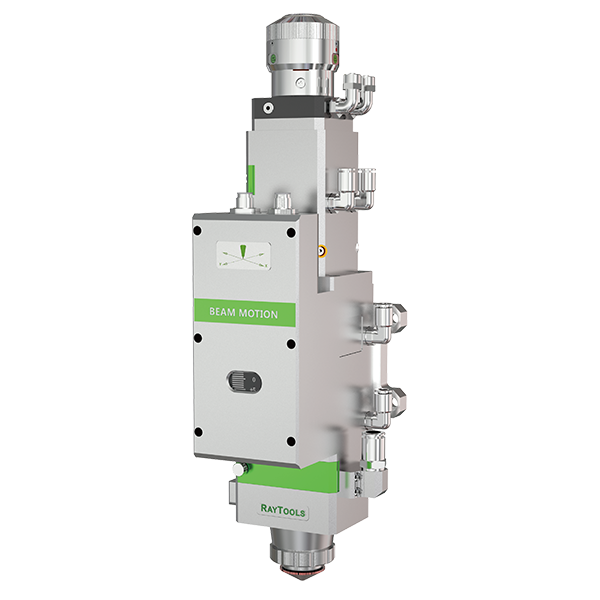

Laser Heads

Laser head from the source of production, there are mainly the following five kinds, every one have their own advantages and characteristics.

1.Imported brands: PRECIETC, IPG.etc The main features are stable quality, good cutting results, the only drawback is the price is very high.

2.Three-way domestic: WSX, Raytools, Porad, OSPRI, Au3tech . etc. The versatility is better, can be used in various types of fiber machine with a variety of fiber laser and control system to use. Internal accessories are conventional models, the later maintenance is very convenient, the cost is also very low.

3.Fiber machine manufacturers independent research and development: Trumpf, Bystronic, PENTA, Yueming, Bodor.etc. The main feature is to match their own research and development of the control system, bed, laser and so on. Generally only large manufacturers will develop their own sales of laser head, so the quality is still guaranteed.

4.Control system with a laser head: FSCUT, Weihong.etc The main feature is the high degree of intelligence, can do a deep interaction with the system, the cutting effect is very good, very stable, for example, FSCUT matching the BLT series of laser heads, the reputation in the industry is very good.

5.Laser manufacturers self-developed laser head: Maxpower, IPG. Etc, mainly used in their respective ultra-high-power lasers, such as Maxpower’s 60KW, IPG’s 20KW, characterized by a high degree of matching.

To summarize, if you buy the equipment of well-known manufacturers, you can choose their self-developed laser head, because the quality is guaranteed. If the pursuit of cost-effective equipment, it is recommended to choose to select the tripartite domestic laser head, because the quality is more stable, and later maintenance is also more convenient. Secondly, the system comes with a higher degree of matching laser head. If you choose ultra-high power laser, you can also consider the laser head that comes with the laser manufacturer.

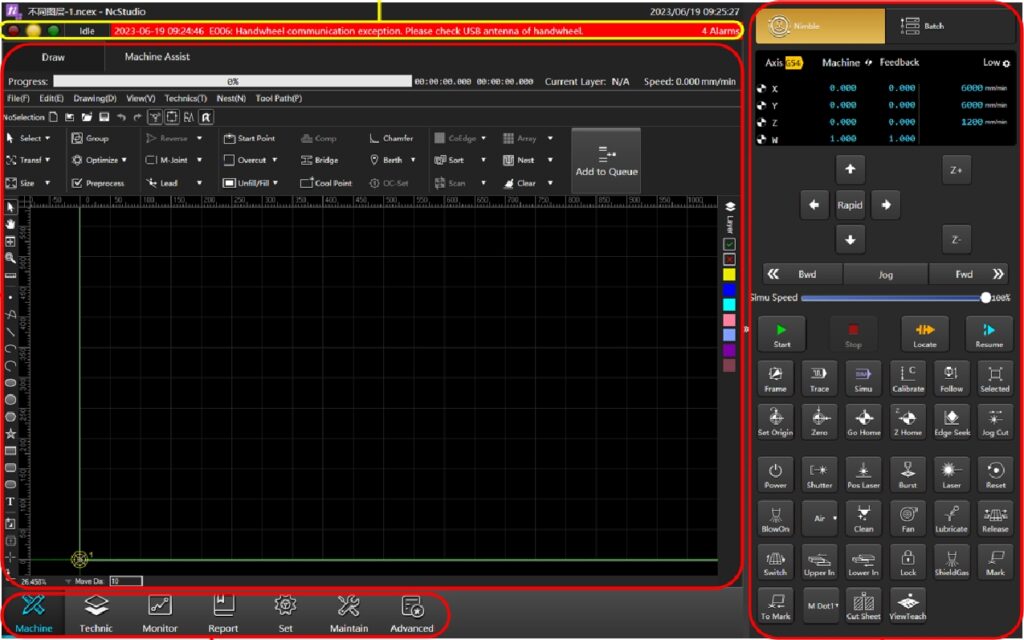

Control System

Control system is to manipulate the whole equipment for the work of the center, we generally mainly from the smoothness and stability to rank the advantages and disadvantages of the control system. There are mainly the following types.

1.Chinese Domestic systems:FSCUT, Weihong.etc, these two are now on the market the mainstream of the two domestically produced control system, its main feature is very good human-computer interaction, novice learning very quickly, the interface layout is more reasonable, and the price is cheaper relative to imported systems.

2. Imported Brand:Siemens, BECKHOFF, FANUC, FAGOR. Among them, FANUC and FAGOR have a more mature control system for fiber optic machines, can be used directly. But Siemens and BECKHOFF are semi-finished products, manufacturers need to carry out secondary development. The main feature is high stability, but the price is relatively higher, and the update speed will be slower, the operability is not as good as the domestic system. Not many domestic manufacturers use imported control systems, generally speaking, only in the high-end equipment will choose to use. General-purpose laser machine will generally use domestic systems.

3.Fiber lasermachine manufacturers customized systems: JIATAI-FSCUT10000, PENTA-Italy Ellen, HSG-Weihong6000M, QUICK-BECKOFF.

In summary, if you are buying equipment from a well-known large manufacturer and they happen to have a customized system, give preference to the customized form factor. If the pursuit of cost-effective manufacturers, you can choose domestic systems. It is not recommended to buy imported systems, the later technical support may not be able to catch up with domestic.

Machine Frame Bed

Bed is a difficult to bring a unified comparative measure of the configuration, but also many customers in the choice of equipment is most likely to ignore a point, different bed in the price of different customers will be confused, but it is no less important than the above three configurations, a good bed not only improves the cutting performance of the equipment, but also greatly extends the service life of the equipment, so how should we choose? The following five common market bed introduction hope can help you.

1. Casting Steel bed

Also called cast iron bed, the whole bed made by the Molten iron casting, rigidity and stability is very high, suitable for all types of metal cutting laser cutter, the body will never be deformed, in principle, the use of the term in 20-30 years. The self-weight of the cast bed is very large, so it will not resonate when cutting at high speed, and the cutting accuracy is very high. The disadvantage is that the process is more complex, the production period is longer, usually takes 45-60 days, the price is very high. Now the market has rarely seen casting bed, only few small laser cutter which making high-precision cutting work will use it.

2. Steel welding bed

It is mainstream bed of cnc and laser cutter,now. the bed as a whole is mainly welded from the steel plate, after quenching and annealing treatment, the duration of about 30 days, the overall rigidity of the bed is better, the weight is also relatively high, a 2500 * 60000mm bed weighs 25 tons or so, which makes the machine resonance in high-speed movement is small, and is not easy to deform, belonging to high cost-effective bed.

3. Square tube welding bed

Characterized by cheap, short processing cycle, can be rapid production, mainly for 3KW within the economic models. The disadvantage is that in the rapid cutting, easy to produce resonance, affecting the cutting accuracy, may produce a certain amount of deformation after a long time.

4. Not recommended bed

some factories pursue the ultimate low price, will use some plasma bed, such a bed is very cheap, but its own weight is only 500kgs or so, the movement vibration is very obvious, it is easy to deformation. The service life of this equipment is relatively short, the stability is very poor, but the price is very cheap.

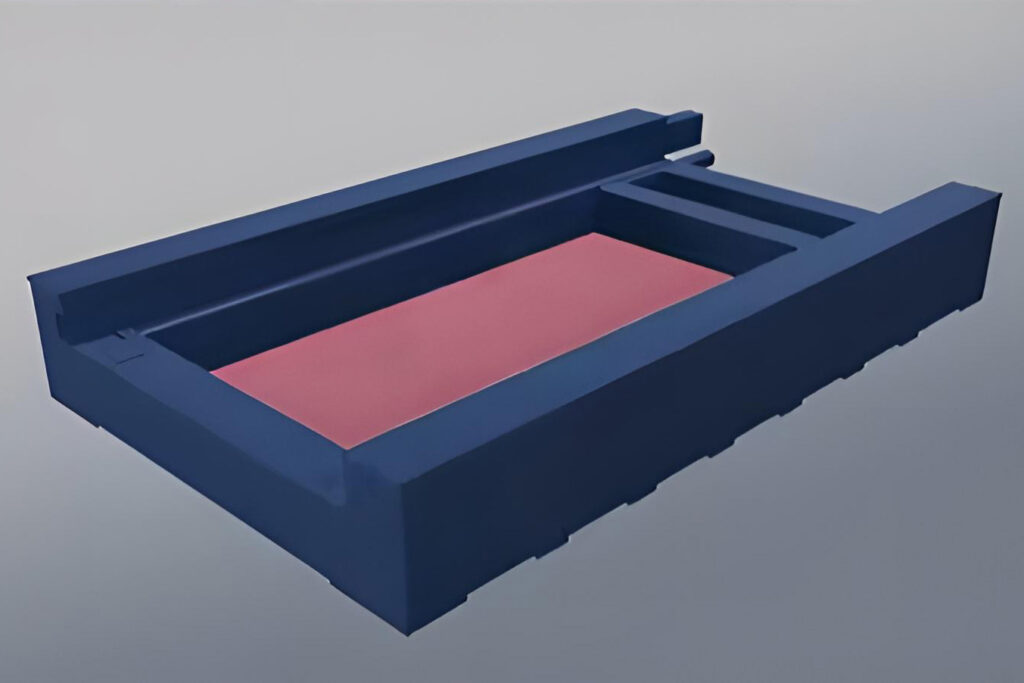

5. New Styles of bed

When laser cutting machine working, the laser head part will produce a large amount of heat, this heat if directly on the bed, will have the risk to make the bed cause thermal deformation, and in the work, there are more than 90% of the cases of the laser head is mainly in the middle of the table work, so in order to minimize the risk of such a new bed now came into being. For example, the hollow bed, the whole is made of plate welding, but there is no or few plate link in the middle part of the platform. Another example is the Ground-rail type bed or Railway type bed, where the platform and the bed as a whole are installed separately and do not affect each other. Such a bed is not easy to be affected by thermal deformation, the body size is not limited, can be unlimited extension, generally speaking in the machine size are in 2500 * 12000mm above. The disadvantage is that the precision is not as high as the integrated bed, the installation process is more complex. Mainly used in 12KW, 20KW 30KW, 40KW, 60KW and other ultra-high-power machine cutting medium-thickness plates.

The above is an overview of the characteristics of each type of bed. Generally speaking, our suggestion is that if the budget is limited, you can consider the tube welding bed within 3KW; for 4KW and above, we suggest the steel welding bed. And for the ultra-high-power machine, which mainly cut medium-thick plates and requires a large working area, you can choose the ground-rail type bed. But the above can’t be the only standard of the bed, for example, some plate welding bed using very thin plate, tube welding bed using the thickness of the rigidity of the pipe and so on, if you need to know specifically, please contact us.

Contact Us to Get A Quotation

How to Maintain Laser Cutting Machine

The normal operation of many mechanical devices require regular maintenance and repair, fiber laser cutting machine is no exception, regular maintenance and repair can effectively extend the service life of the laser machine, to guarantee that the cutting effect, to avoid the emergence of sudden failure. So how to maintain the laser cutting machine? Please refer to the following.

Daily maintenance

Every day before starting the machine’s checking

- Check the cleanliness of the protective lens, if there is dirt or burnt spots affecting the use of timely cleaning or replacement.

- Check whether the ceramic ring is loose, affecting the stability of the equipment cutting operation.

- Check the copper nozzle, if the copper nozzle mouth irregularities have obvious scars in time to replace the copper nozzle each time after the replacement of the copper nozzle need to carry out the floating head calibration and check the center, to avoid affecting the cutting effect.

- Return to the origin, daily start the machine to perform the origin action.

- Check the gas source, including the gas source of the residual gas to meet the production, the gas circuit has no air leakage.

- Clean the dust cover, check the integrity and stability of the dust cover, clean the dust cover of iron chips, iron and other foreign objects.

At the end of each day’s work

- Clean the metal residue and dust on the table surface in time.

- For the cutting head, use special cleaning tools (such as soft brushes, etc.) to gently wipe the protective and focusing mirrors to remove dust and dirt from the surface, taking care not to wipe too hard to avoid damaging the lenses.

- Turn off the power of the equipment, wait for the equipment to cool down, clean and lubricate the guide rail.

Regular maintenance (in weeks)

Lubrication system

Check the oil level of the oil pot, add lubricant in time, automatic lubrication system oil pump oil is too low, the oil pot will be alarmed, use Mobil 46 to re-inject oil.

For guide rail lubrication, after the equipment is powered off, Z-axis guide rail and silk rod are cleaned with a clean cloth, apply appropriate amount of lubricant after cleaning, and clean the X-axis and Y-axis guide rail racks every week.

Water tank and circulating water system

1.Set the temperature 25 to 26 for the low-temperature zone and 28 to 29 for the room-temperature zone in summer, and install an air conditioner for the laser power supply with the temperature set at 22 to 25. Set the temperature 22 to 23 for the low-temperature zone and 24 to 25 for the room-temperature zone in winter.

2.Change the water weekly (using distilled water) and clean the water tank every time you change the water, such as the filter element, water tank, condenser, filter, and fan, which needs to be cleaned with air at the same time and cleaned with rags and brushes.

Mechanical part

- Clean the guide rack and remove the sludge and other dirt, for the dirtier guide you can use WD40 to spray it first and then clean it, after spraying then use a rag to wipe it.

- Check the wear and tear of rack and pinion, and replace it in time if there is serious wear and tear.

Regular maintenance (in months)

- Check whether the laser is working normally, including whether the laser power, wavelength and other parameters are stable.

- Check the electrical system, including cables, connectors and electronic components, tighten loose connectors to ensure the stability of the electrical circuit, and regularly check the electrical panel to find and solve potential faults.

Regular maintenance (in quarterly or half-yearly basis)

- Replace damaged consumables, such as cutting head nozzles and protective mirrors, to ensure cutting quality.

- Maintenance of the industrial computer, once every six months, once every three months in harsh environments, requires cleaning the industrial computer. Remove the fixing bar, remove the cover, you can clean the motion control card and memory module, please use a clean rag to clean.

Long-term downtime maintenance

- If the machine is not used for a long time, you need to use paper tape to seal the bottom of the copper mouth of the cutting head to prevent dust from entering the inside of the cavity, so as to ensure that the back of the normal cutting use.

- Air compressor, because the air compressor will produce water in the process of operation, put the water clean, to avoid a long time without corrosion of the air compressor.

- water cooler if the inside is water as far as possible to put it out, because time long time not in the factory, if suddenly cold for icing is easy to freeze the laser. First put the water out, the two tubes can be taken off, with a gas pipe to the inside of the water to blow out, antifreeze can not be dealt with, you can wait 3 months or so to replace it.

The above is the basic maintenance procedures for fiber laser cutting machine, the specific maintenance cycle and content can be adjusted according to the use of equipment and manufacturer’s recommendations!

What is the Trend Of Laser Cutting Machine Industry

The overall trend of the fiber laser cutting machine market is one of steady growth, especially in Asia, especially China, where the market demand has risen significantly, leading the industry. With the gradual recovery of the global manufacturing industry and continuous technological advancement, the fiber laser cutting machine market is showing steady growth.

The global fiber laser cutting machine market is expected to reach $20.847 billion by 2029, at a CAGR of 8.69%.

In terms of technology, the R&D dynamics of fiber laser cutting machines are focused on increasing cutting speed, optimizing energy efficiency, and enhancing operational intelligence to accommodate increasingly complex manufacturing needs. This includes the broadening of product categories, to the “full band, full pulse width, full power, full application” direction, the formation of the whole industry chain layout from basic scientific research to the productization of the spectrum of batch manufacturing.

Market demand, fiber laser cutting machine is widely used in many fields, including household appliances, automotive industry, aerospace and shipbuilding, general mechanical processing. Especially in Jinan, the market demand in 2024 increased by 26% compared with 2023.

In addition, the market demand for 3D fiber laser cutting machines is also increasing, especially in the field of precision machining and efficient production.

In terms of supply chain and competitive landscape, the supply chain of the fiber laser cutting machine industry involves high technological and supply chain management requirements from the manufacturing of the laser source and optics to the assembly and distribution of the final product. Key competitors include internationally renowned industrial equipment manufacturers such as Trafigura and Daqo Laser, as well as innovative companies specializing in laser technology, which compete fiercely in terms of product performance and service.

What Does Customer Say Us?

Are you still unsure about purchasing CNC machines from Light CNC Laser? The best way to gain confidence is by reading authentic testimonials from our actual customers. We regularly conduct satisfaction surveys, inviting our customers to provide honest feedback on our products and services. As you’ll see in the following reviews, many users have shared their personal experiences with our machines. Light CNC Laser gathers insights from customers based on their experiences with the CNC machines they have purchased, as well as their opinions on the buying process, repair, and maintenance services. We are committed to providing high-quality products and exceptional services, which motivates us to continually innovate and grow.

David Harrison

The steel laser cutter I bought from Light CNC Laser works perfectly! What impressed me the most was their after-service. The team was always ready to help, providing quick and efficient support whenever I needed it. Great experience overall!

Edward Collins

The best plasma cutter I purchased from Light CNC Laser arrived in incredibly strong packing. I was really impressed with the care they took in securing everything. It arrived in perfect condition, ready to work straight out of the box!

James Anderson

I purchased an industrial laser cutter from Light CNC Laser, and I couldn’t be happier with the quality. The machine is incredibly reliable and precise, and it’s made a huge difference in my production line. Truly top-notch equipment!

George Robinson

I had some technical questions after receiving my best plasma cutter, and the online support from Light CNC Laser was fantastic. They patiently walked me through everything, ensuring I got the most out of my new machine. I’m very satisfied!

Thomas Bennett

Light CNC Laser’s steel laser cutter has exceeded my expectations. The working effect is amazing, with clean, precise cuts every time. It’s clear that this machine was built with high standards. I’m thrilled with the results!

Stephen Brooks

Light CNC Laser’s metal plasma cutter is a solid machine, but what really stands out is their maintenance support. They’ve been there whenever I needed them, keeping my machine running smoothly. Their commitment to customer service is exceptional!

Charles Miller

I was worried about timing, but Light CNC Laser delivered my steel laser cutter right on schedule. The punctual delivery allowed me to meet all my deadlines without any stress. Absolutely dependable service

Franklin Morgan

As a first-time buyer, I was nervous, but the professional suggestions from Light CNC Laser’s team made all the difference. They guided me through the process, helping me choose the perfect laser cutting machine manufacturer for my needs. I couldn’t be more grateful