High Precision, Low Energy Consumption, Long Lifespan

Fiber Laser Cutter

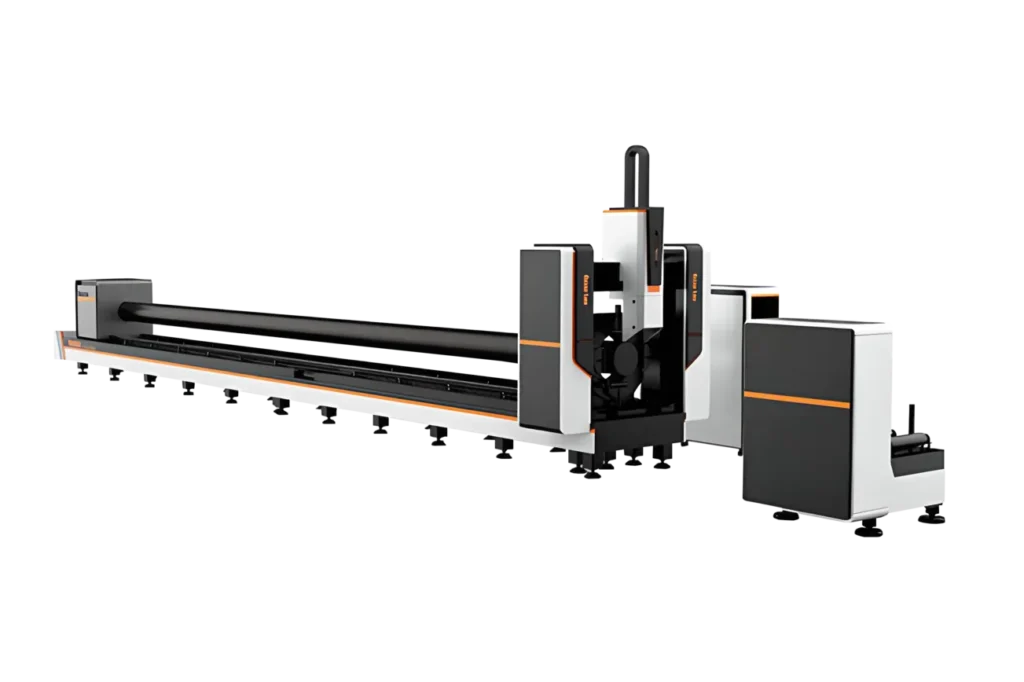

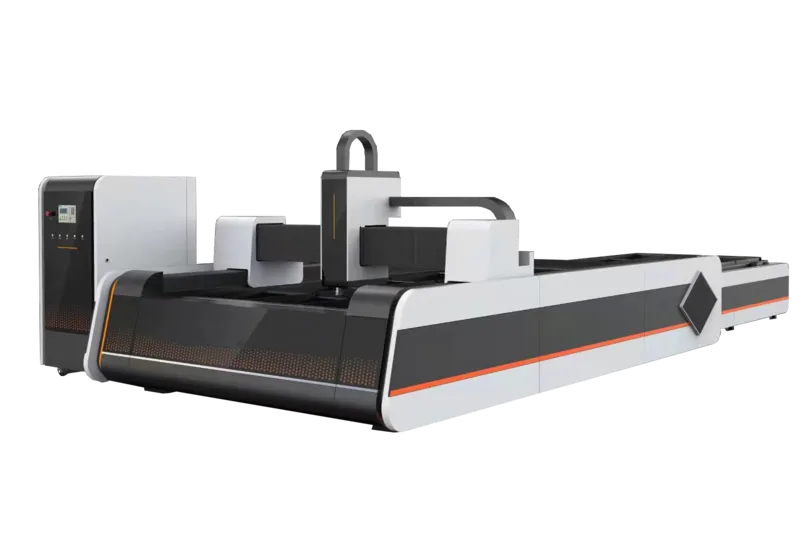

Figure 1: Typical fiber laser cutting machine (example). Modern fiber laser cutting machines feature robust and stable structures, high cutting precision, excellent energy efficiency, and a significantly longer lifespan than traditional equipment. Taking the core fiber laser as an example, high-end brands like IPG and Raycus produce fiber lasers with a rated lifespan of approximately 100,000 hours (about 11 years of continuous use)(^1). This means that even with daily continuous operation, its lifespan can reach decades, maintaining high cutting performance throughout. In contrast, the lifespan of older CO₂ laser tubes is typically only a few thousand hours. Fiber lasers have no moving parts, resulting in low failure rates and reducing maintenance costs by more than 50% (^1).

The laser cutting head is another critical component, generally integrating a nozzle, focusing lens, and automatic height adjustment system. Common cutting head brands include Switzerland’s PRECITEC and Raytools. Low-power machines often use Raytools heads, while high-power (8-12kW) machines employ German PRECITEC heads (^3). The main wear on the cutting head comes from the optical lenses. Once contaminated or damaged, they absorb laser energy, causing coating damage, and in severe cases, even stopping laser emission (^4). Therefore, regular cleaning of mirrors and focusing lenses is essential to effectively extend the overall lifespan of the lenses and cutting head.

Besides optical components, the control system, transmission system, and electrical components also affect the machine’s overall lifespan. The control system (including CNC cards, drivers, and software) typically lasts many years, based on high-quality PCBs and reliable software. Many domestic systems (e.g., CyPCut) support remote monitoring of IPG lasers, allowing real-time viewing of laser status and output control (^5), aiding in rapid fault diagnosis. Electrical components (such as servo drivers, contactors, switching power supplies, etc.) can typically operate stably for over a decade under conditions of good heat dissipation and dust prevention (^6). Transmission components (guides, ball screws, servo motors, etc.) can also last tens of thousands of hours with regular lubrication (^7). The cooling system (chiller, water pump) depends on water quality and maintenance. When using well-known brands (e.g., S&A), circulating water pumps can usually last over 10 years.

| Component | Typical Lifespan | Key Characteristics |

|---|---|---|

| Laser Source | ≈100,000 hours (10-15 years) | IPG/Raycus fiber laser, high conversion efficiency, no vulnerable parts, lifespan far exceeds CO₂ lasers. |

| Cutting Head | Tens of thousands of hours | Uses PRECITEC or Raytools cutting heads, focusing lens is consumable and requires regular cleaning to prevent coating damage (^4). |

| Control System | Many years | CNC cards, control software, etc. Supports IPG remote monitoring and network diagnostics (^5), high reliability. |

| Electrical Components | Many years | Servo drives, sensors, circuit boards, etc. Keeping electrical cabinets clean and ventilated extends lifespan (^6). |

| Transmission System | Tens of thousands of hours | Mechanical parts like X/Y/Z axis guides and ball screws. Require regular lubrication (^6) for long-term stable operation. |

| Cooling System | Over 10 years | Chiller and piping system. Using high-quality water pumps and regular filter replacement/maintenance ensures long service life. |

Factors Affecting Lifespan and Performance Stability

Environmental factors significantly impact the lifespan of fiber laser machines. Excessive temperature, humidity, or dust can accelerate the aging of electronic components and damage optical parts (^7). Dust adhering to lenses or moving parts can degrade beam quality or hinder movement, thereby affecting cutting precision and equipment lifespan (^8). Therefore, the machine should be placed in a clean, well-ventilated workshop, with dust removal devices and constant-temperature air conditioning installed if necessary.

Operating habits are equally crucial. Overloading or continuous high-intensity cutting consumes the lifespan of various components prematurely (^9). International experience shows that reasonably arranging production loads and avoiding prolonged overuse can significantly extend equipment life (^9). Additionally, correct startup/shutdown sequences and stable power supply (improper power cuts or cold starts can cause shocks to power supplies and light sources) also contribute to stability. Skilled operators, after training, can better grasp key points like pre-startup preparation and fault diagnosis, reducing damage caused by misoperation (^10).

Process materials are also a factor. When cutting highly reflective materials (like copper, brass), unevenness or pulse reflections are common. Improper parameters can exacerbate wear on optical components (^11). Selecting suitable cutting gases (oxygen, nitrogen, or air) and parameters to avoid laser output instability caused by strong reflections or absorption is crucial for protecting the laser source and head lifespan.

Daily Maintenance and Care

Scientific maintenance can significantly enhance the machine’s overall lifespan. Common daily maintenance items include:

- Optical Path & Lens Cleaning: Regularly inspect mirrors and focusing lenses for surface contamination, cleaning at least monthly (^12). Gently wipe with specialized cleaning fluid and lens cloth to avoid scratches. Keeping lenses clean prevents laser absorption leading to coating damage, ensuring cutting quality and equipment lifespan (^13).

- Filter & Ventilation: Remove dust from the electrical cabinet’s ventilation fan and the filter screen on the optical machine cover to ensure good ventilation (^6). A good heat dissipation environment effectively reduces the thermal failure rate of electronic components.

- Mechanical Lubrication: Check and replenish lubricating oil for X/Y/Z axis guides and ball screws weekly (^6). Keeping sliding parts lubricated reduces wear and improves motion accuracy.

- Cooling System Maintenance: Confirm chiller circulating water level and temperature are normal before startup (^14); regularly replace coolant or reverse osmosis purified water to prevent corrosion. Keeping the cooling system unobstructed prevents performance degradation of the laser and cutting head due to overheating.

- Gas Pressure Check: Check the pressure of laser working gas (e.g., nitrogen) and cutting assist gas (oxygen/nitrogen) daily before startup (^15). Replace cylinders or pressurize promptly if pressure is insufficient to avoid affecting cutting results.

- Electrical Check: Inspect cable connections for tightness and wear; check signal indicator lights and limit switches for normal operation (^15). Repair abnormalities promptly to prevent faults caused by power loss or signal loss.

- Working Environment: Keep the work area clean, remove debris after work, and turn off the power (^14). Avoid strong magnetic fields or high-dust areas during installation; ensure stable power supply around the machine.

According to business summaries, regular preventive maintenance can greatly improve equipment reliability and service life. Following the inspection cycles and specifications in the manufacturer’s maintenance manual for tasks like lens cleaning, filter replacement, and lubrication keeps the machine in optimal condition long-term (^16). For example, timely lens and filter cleaning can

avoid optical path damage and improve cutting quality; timely lubrication replenishment delays mechanical component wear (^16). Maintaining good maintenance habits is key to extending the life of laser cutting machines (^17).

Light CNC Laser Brand Advantages

As a representative of China’s fiber laser cutting machines, Light CNC Laser has significant advantages in quality control and technical selection. It can be equipped with international brand lasers (e.g., Germany’s IPG or China’s Raycus fiber lasers) and high-end cutting heads (Germany’s PRECITEC or Switzerland’s RAYTOOLS), meeting diverse customer performance needs (^18). IPG lasers offer higher beam quality and long-term stability, while Raycus lasers have cost advantages and high cost-performance (^19); for high-end cutting, using PRECITEC cutting heads enables faster cutting speeds and more stable processing results (^20). Furthermore, Light CNC’s manufacturing structure is optimized, often using cast beds or reinforced gantry beams to ensure rigidity and stability during high-speed cutting.

In after-sales service, Light CNC Laser provides remote monitoring and cloud-based support, responding promptly to user needs. This aligns with industry trends: major domestic laser companies propose "real-time monitoring, remote support" solutions, using online diagnostic systems to record machine operation logs and abnormal alarms for preventive maintenance (^21). Users can remotely adjust parameters, upgrade software, and obtain fast technical support (^22). Light CNC also provides training and operational guidance to ensure operators use equipment correctly, improving equipment lifespan and cutting quality.

Overseas User Reviews and Cases

Overseas buyers generally give positive reviews to Chinese-made fiber laser cutting machines, particularly recognizing their high cost-performance and stability. Statistics show that many users report stable performance even after years of continuous operation. For example, one laser equipment manufacturer summarized user feedback finding that its fiber laser marking machine achieved a 100,000-hour lifespan after 24/7 continuous operation; most customers reported good operation after over 5 years of use (^23). Another foreign media report also stated that fiber lasers can last about 100,000 hours, with operating and maintenance costs 50% lower than CO₂ laser machines. These cases demonstrate the reliable long-term performance and low maintenance costs of Chinese brand fiber laser machines. Users often only need routine cleaning and lubrication maintenance to ensure long-term efficient operation, saving significant repair costs.

In summary, the lifespan of fiber laser cutting machines is primarily determined by key components like the laser source, optical head, and moving parts. Correct operation and maintenance can significantly extend their service life (^19). Light CNC Laser, with its selection of premium imported light sources and cutting heads, robust mechanical design, and comprehensive service system, has advantages in quality and stability. Overseas user experiences also confirm that with proper maintenance, fiber laser cutting equipment can operate stably for years with consistent cutting efficiency and low maintenance costs, providing strong technical support for downstream processing (^21, 22).

References: The above data and recommendations are synthesized from industry materials and manufacturer manuals (^1, 7, 15, 16, 21, 5, 19, etc.).

1, 22 FAQS | Ward’s Manufacturing

https://www.wardsmanufacturing.com/faqs

2, 7, 9, 10, 11 How Long Do Laser Cutters Last? – Baison

https://baisonlaser.com/blog/laser-cutters-life/

3, 8 Important Components of Fiber Laser Cutting Machine – MORN LASER

https://www.momtech.com/blog/fiber-laser-cutting-machine/8-important-components-of-fiber-laser-cutting-machine/

4, 6, 12, 14, 15, 16 Daily Maintenance of Fiber Laser Cutting Machine (Chinese Source)

https://www.dwlaser.com/newshow/gxjgggjcbywhynx.html

5 BC-2801GA Multi-axis Motion Control System (Chinese Source)

https://d.fscut.com/wordpress-fscut/2022/12/FSCUT2000S%E7%94%A8%E6%88%B7%E6%89%8E5%86%8CV4.0.pdf

8, 13 Tips for Maintaining and Extending the Lifespan of Your Fiber Laser Cutting Machine | Oree Laser

https://www.oreelaser.com/blog/Tips-for-Maintaining-and-Extending-the-Lifespan-of-Your-Fiber-Laser-Cutting-Machine-393.html

17, 21 laser marker machine Archives – XTLASER

https://www.xtlaser.cz/tag/laser-marker-machine/

18 IPG vs Raycus Laser Comparison Guide 2025 New – SC Machinery (Chinese Source)

https://www.shen-chong.com/zh/jpg-vs-raycus-laser-comparison-guide/

19, 20 Intelligent Interconnection in the Era of Smart Manufacturing: Advantages of Laser Cutting Machines (Chinese Source)

https://www.hansme.com/news-detail/i-186.html