Key Purchasing Factors

Performance Parameters: The power and rated current of the plasma cutting machine determine the maximum metal thickness and cutting speed. Generally, higher current plasma sources can cut thicker metals. For example, data from the domestic Huayuan brand shows that at 63A, it can cut carbon steel approximately 25mm thick, while at 400A it can reach 50mm (^1). Additionally, cutting speed should be considered: higher power enables faster feed rates, improving productivity.

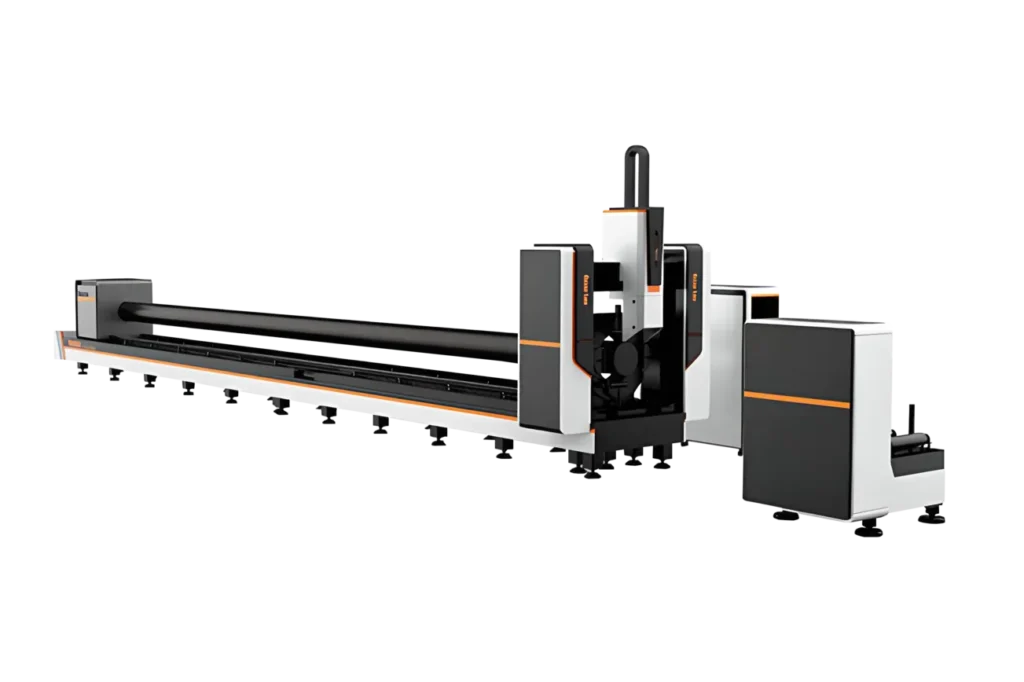

Plasma Cutting Machine

-

Control System: A high-quality CNC system determines the operating experience and stability. Many domestic cutting machines are equipped with user-friendly control panels and easy-to-use software (^2), supporting the import of common file formats like DXF, making it easy for both domestic and foreign customers to get started. System stability is also crucial. Choose reliable and stable controllers (e.g., Syntec, Ruiba) and high-precision servos/drives to ensure long-term machining accuracy and reliability.

-

Parts Availability and After-Sales Service: Convenient access to spare parts effectively reduces downtime risks. Chinese manufacturers can typically provide common consumables and wear parts quickly and ship them at low cost via sea or air freight (^3). When selecting a machine, verify whether the manufacturer has agents or service centers in your local area or neighboring countries to ensure timely technical support and spare parts in case of equipment failure. A robust after-sales service network is also vital for ensuring long-term operation.

-

Cost and Value for Money: Domestic models are usually significantly cheaper than European and American brands (^4), offering an economical choice for budget-constrained businesses. For example, cutting machines with similar specifications are often cheaper in USD for domestic equipment. Despite the low price, ensure the product configuration, performance, and reliability meet requirements—avoid choosing based solely on low price. It is recommended to set a reasonable budget based on processing needs, compare configurations and warranties from different manufacturers, and select a model that offers true high cost-effectiveness.

-

Brand Reputation and Reputation: Prioritize brands with a strong international reputation. Some leading Chinese companies have decades of history and have served tens of thousands of customers (^5). Many user reviews indicate that Chinese CNC machines offer high value for money while meeting basic production requirements (^6). Investigate brand reputation through industry exhibitions, media reports, and other user reviews. Exercise caution when purchasing products from unverified small manufacturers.

Machine Selection Recommendations for Different Applications

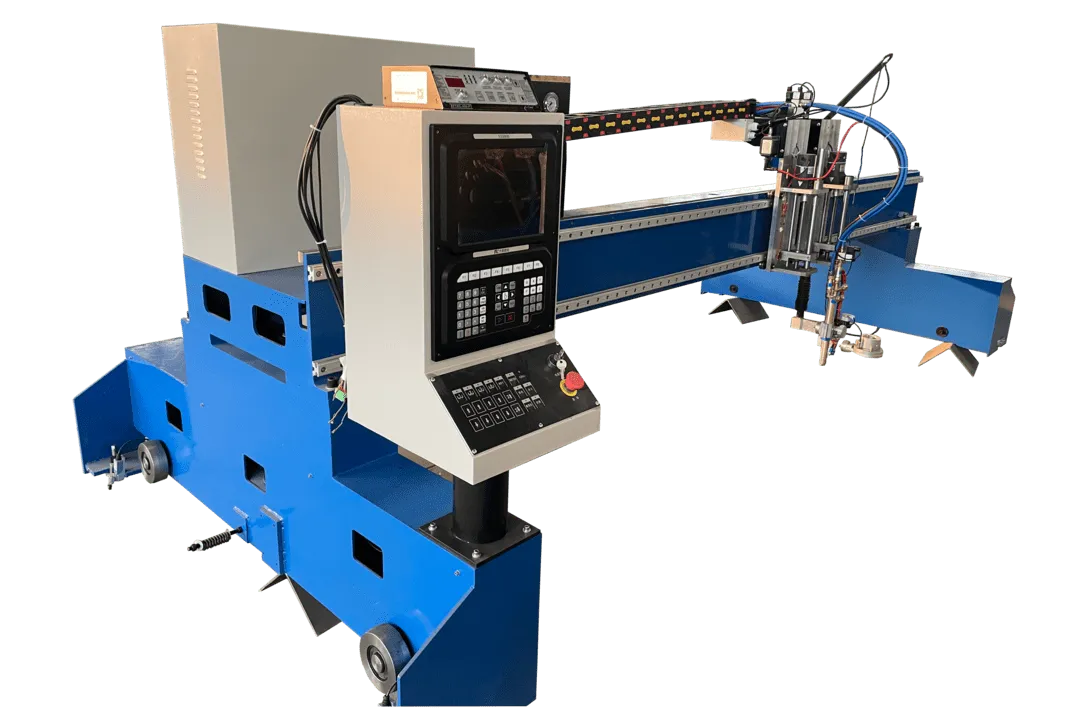

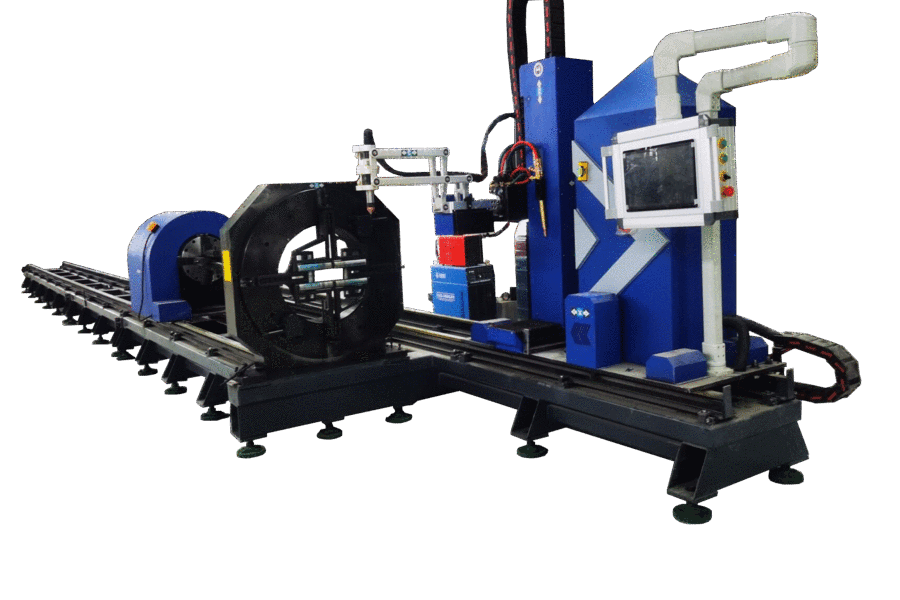

8 axis plasma tube cutting machine

-

Sheet Metal Processing: Used for cutting after shearing or stamping, often involving thin to medium-thickness steel plates (≤15mm). Recommended: Medium-power gantry-type plasma cutting machines equipped with automatic nesting software to improve material utilization. For cutting stainless steel or aluminum plates, nitrogen high-definition plasma cutting can be used to achieve a smoother cut surface.

-

Steel Structure Processing: Used for cutting thick plates like profiles, channel steel, H-beams, and often requiring bevel cutting. Recommended: Large, heavy-duty gantry plasma machines equipped with automatic cutting functions and powerful loading/unloading systems to meet high-thickness and bevel-cutting requirements. Research indicates that plasma cutting machines are widely used in fields like steel structure manufacturing (^7). Such models typically use high-power plasma sources (200A+) and rigid frame structures to ensure sufficient cutting capacity.

-

Automotive Repair: Body panel repair often requires cutting steel plates around 10–20mm thick. Recommended: Portable or small benchtop CNC plasma machines. Advantages include flexibility and mobility, making them suitable for localized disassembly/welding tasks in workshops. Optional accessories like water-cooled cutting tables or fume extraction devices can reduce smoke and dust during cutting, improving workshop environmental safety.

-

Artistic Cutting: Used for making decorative artworks, signs, etc., focusing on detail and shape. Recommended: High-precision plasma cutting machines combined with fine profiling and multi-angle cutting processes for more precise textures. If budget allows, consider combining with laser cutting for ultra-fine patterns. Since speed is less critical for this type of processing, the key is the machine’s stable cutting capability for complex patterns.

Industry Development Trends

-

Intelligence and Connectivity: Modern plasma cutting machines are evolving towards digitization and networking. New models commonly feature built-in Ethernet interfaces, allowing networked coordination between the cutter, torch height controller, and gas flow controller to improve cutting quality and efficiency. High-precision plasma machines integrate with CAM nesting software for fully automated production. Some manufacturers also offer Android-based remote control apps, enabling program uploads and operation monitoring via smartphones, simplifying operational workflows.

-

Automation Integration: To improve production efficiency, automatic loading/unloading, material handling, and dust removal/recycling systems are becoming standard. Fully automated production lines integrate sheet feeding, cutting, sorting, and dust collection, significantly reducing labor costs. Some domestic manufacturers have developed integrated production lines combining cutting machines with robotic arms and environmental equipment to meet high-volume industrial processing needs.

-

Green and Energy Efficiency: Driven by sustainable manufacturing, plasma cutting technology is placing greater emphasis on energy savings and environmental protection. Studies show plasma cutting machines consume less energy and produce less waste compared to traditional cutting methods (^7). New high-definition plasma technology enables more precise material cutting, reducing slag generation and material waste, aligning with green production concepts. Future cutting equipment will continue adopting energy-efficient plasma sources and eco-friendly material filtration systems to reduce environmental impact.

Recommended Chinese Brands and Models

Below are several representative Chinese manufacturers and their models suitable for foreign trade:

| Brand | Representative Model | Application Scenario | Advantages |

|---|---|---|---|

| Light CNC Laser (Light Laser) | L-Series Light/Heavy Gantry | Sheet metal processing, sign cutting | Lightweight body, affordable price, suitable for SMEs |

| LANCNC (Wuhan Lansun) | LC-Series Heavy Gantry | Steel structure processing, large plate cutting | 30+ years industry experience, served 10,000+ customers (^5) |

| Perfect Laser (Wuhan) | PL-Series Gantry | Sheet metal processing, advertising engraving | Major laser equipment manufacturer, products exported to 180+ countries (^{12}) |

| JOY CNC (Jin Shengyang) | JOY-1325, etc. | Advertising signs, model making | Precision small machines, global sales and service network (^{13}) |

The above brands and models are examples only. Actual procurement should involve further research into other manufacturers based on business needs and budget. When selecting, focus on the core parameters (cutting area, plasma source specifications, etc.) and application scope of the corresponding model to choose the equipment best suited to your business scenario.

References: Official websites of each brand and industry reports (^5) (^7) (^1) (^{12}) (^3) etc.

- CNC Plasma Cutting Capacity Thickness Chart – EagleTec CNC

https://www.eagletec-cnc.com/news/cnc-plasma-cutting-capacity-thickness.html -

-

-

- Are Chinese CNC Machines Any Good?

https://www.stylecnc.com/blog/are-chinese-cnc-machines-any-good.html

- Are Chinese CNC Machines Any Good?

-

-

- Cutting Machine Manufacturer, CNC Cutting Machine, CNC Plasma Cutting Machine Supplier – Wuhan Lansun Technology Co., Ltd.

https://lan-xun.en.made-in-china.com/ -

-

-

-

- CNC Plasma Cutting Machines Market Size, Report 2025-2034

https://www.gminsights.com/industry-analysis/cnc-plasma-cutting-machines-market

- CNC Plasma Cutting Machines Market Size, Report 2025-2034

-

-

-

- Company Overview – Perfect Laser (wuhan) Co., Ltd.

https://perfectlaser.en.alibaba.com/ - Plasma Cutting Machine Manufacturer, CNC Engraving Machines, Letter Bending Machine Supplier – Wuhan King Suntime CNC Equipment Co., Ltd.

https://joycnc.en.made-in-china.com/