Heavy-Duty CNC Plasma Pipe Cutter | Precision Cutting for Large Diameter Tubes

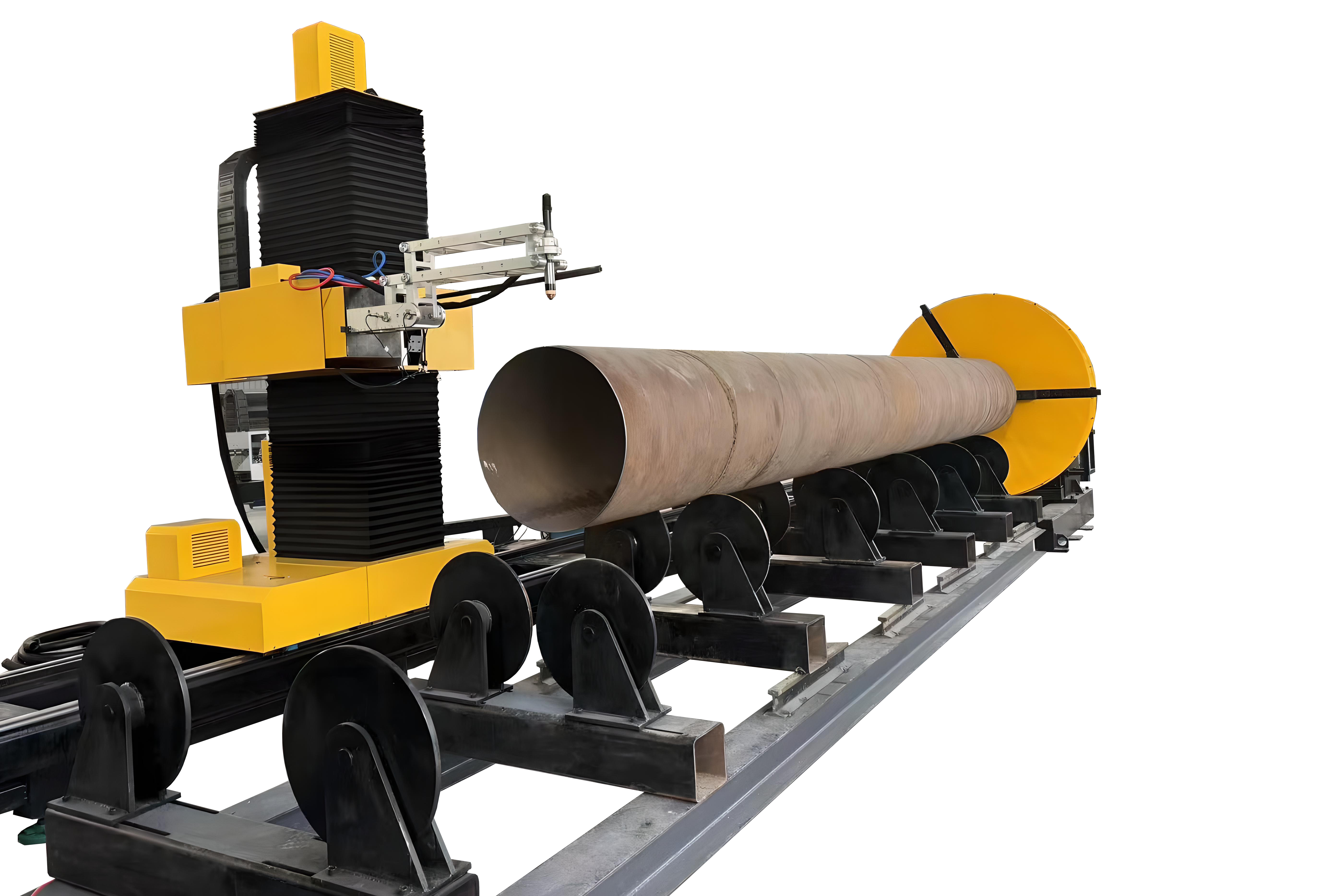

Explore our heavy-duty CNC plasma pipe cutter, designed for large diameter tubes (800mm-2000mm) and lengths up to 24m. Capable of precise bevel cutting for seamless welding.

Large CNC Plasma Pipe Cutter for Beveling and Long Metal Tubes

Model:LT80120-BPR(LT15120-BPR,LT20120-BPR)

Working area: 800mm(1500mm, 2000mm as options) diameter*12000mm(24000mm as options) length

Support Plasma Power: 160A, 200A, 300A, 400A

Price Range: $500 00 – $115 000

Warranty time: 1 year for the whole machine

Delivery time: 7-10 workdays

Technical Support Time: Free Lifetime for All Clients

Machine Videos

Technical Parameter

| Model | LT80120-BPR(LT15120-BPR,LT20120-BPR) |

|---|---|

| Max Process Pipe Diameter | 800mm(1500mm, 2000mm as options) |

| Max Process Length | 12000mm |

| Lathe bed | Very thick steel structure |

| Reposition precision | 0.02mm |

| Processing precision | 1mm |

| Maximum cutting speed | 9000mm/min |

| Torch Height control mode | Automatic ARC |

| Cutting thickness | Max 40mm carbon steel for plasma |

| Plasma power supply | LGK / Hypertherm 160A/ 200A/ 300A/ 400A |

| Control system | Startfire/Fangling |

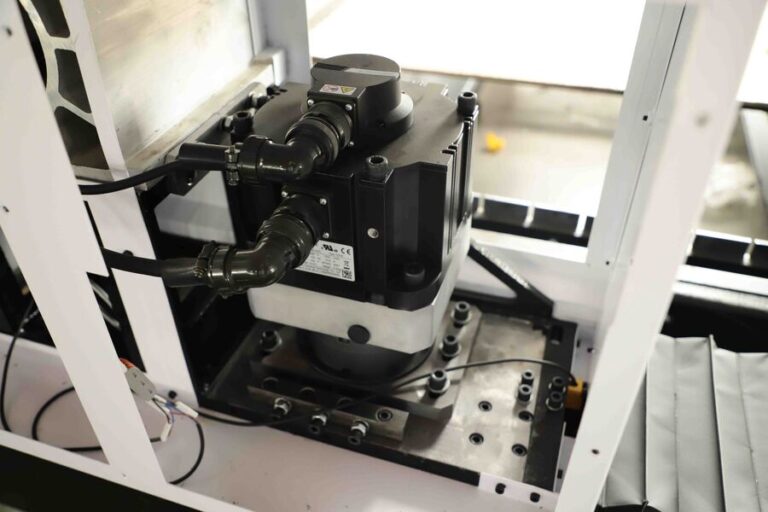

| Motors | Japanese Panasonic servo motor |

| Software | Startcam/Fastcam |

| Weight | 8000KGS |

| Working voltage | 380V three phase/ 50hz |

| Plasma Air Pressure | Max.0.8Mpa |

| Working Temperature | -10°C-60°C. Relative Humidity, 0-95%. |

| LCD Display | Touch screen |

Machine Features

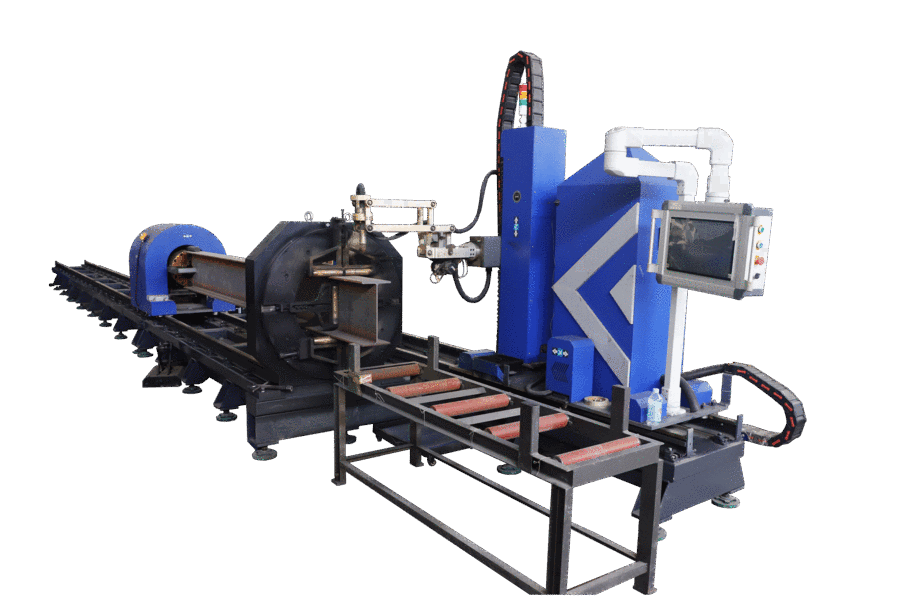

Unique Advantages:big strong machine structure, specialize in cutting big diameter round pipe, from 800mm to 2000mm diameter pipe. widely used in factory building, bridge building, city building.etc

Big diameter Chucks: Aodp to use big size manual driver chucks, can easily tight the large diameter pipe.

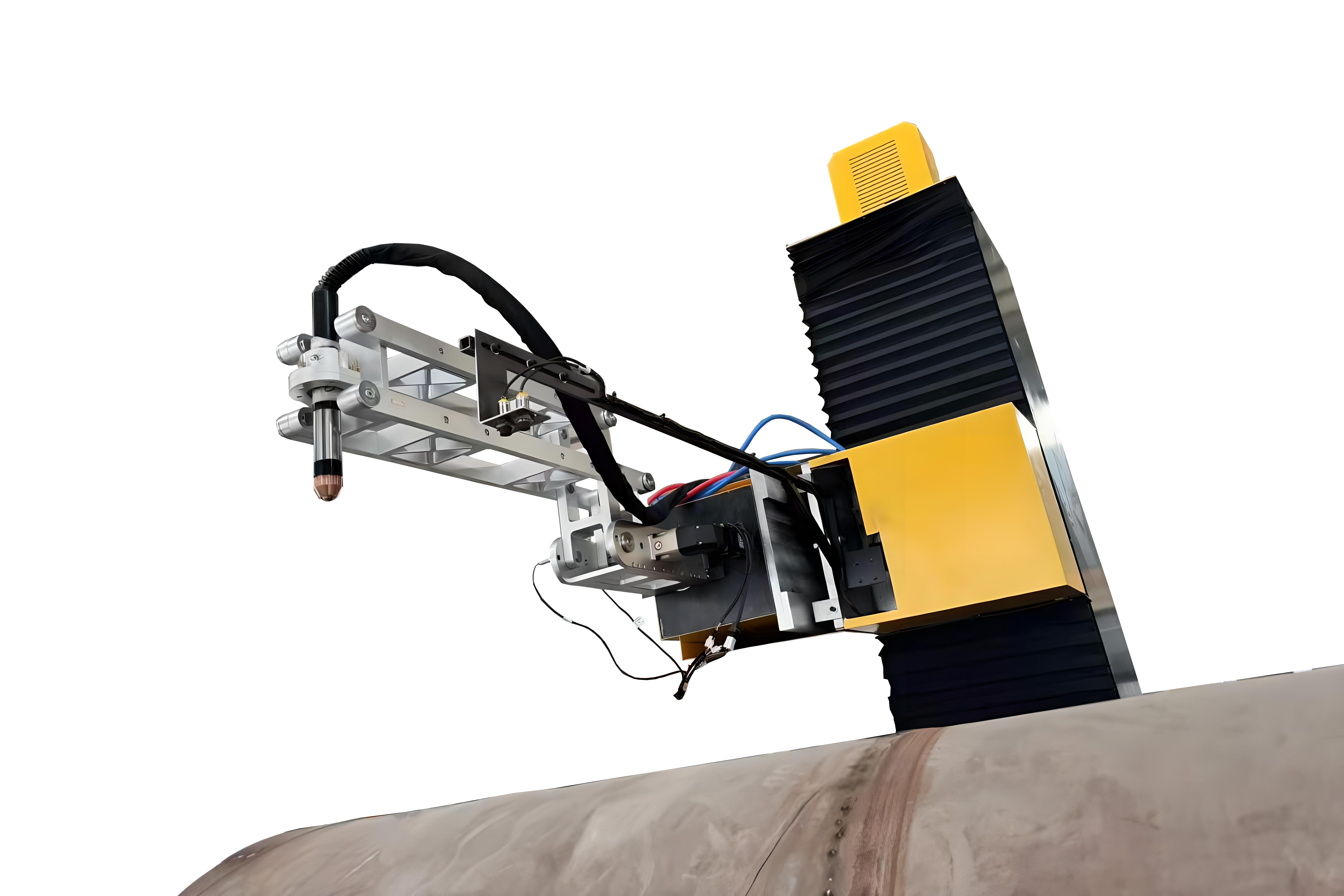

Professional Plasma Head: Professional 8 axis plasma head, suitable for cutting big diameter pipe and also have bevel cutting functions

Plasma Power Supply: According to materials’ thickness, can adopt LGK or Hypertherm 160A, 200A, 300A, 400A plasma source, guarantee the perfect cutting effect and working efficiency.

| Different Powers' Plasma Cutting Supply Technical Parameter | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chinese LGK Plasma Power Supply | ||||||||||||||||

| Power | LGK-63IGBT | LGK-120IGBT | LGK-160IGBT | LGK-200IGBT | LGK-300HD | LGK-400HD | ||||||||||

| Working Effect | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | ||||

| Carbon steel | 25mm | 15mm | 45mm | 25mm | 60mm | 30mm | 70mm | 35mm | 100mm | 0.3-50mm | 120mm | 1-60mm | ||||

| Stainless steel | 20mm | 12mm | 36mm | 20mm | 48mm | 24mm | 56mm | 28mm | 80mm | 40mm | 95mm | 48mm | ||||

| Aluminum | 15mm | 9mm | 27mm | 15mm | 36mm | 18mm | 42mm | 21mm | 60mm | 30mm | 72mm | 72mm | ||||

| Brass | 15mm | 9mm | 27mm | 15mm | 36mm | 18mm | 42mm | 21mm | 60mm | 30mm | 72mm | 72mm | ||||

| American Hypertherm Plasma Power Supply | ||||||||||||||||

| Power | Powermax45 SYNC | Powermax65 SYNC | Powermax85 SYNC | Powermax105 SYNC | Powermax125 | MAXPRO200 | XPR300 | HPR400XD | ||||||||

| Working Effect | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut |

| Carbon Steel | 29mm | 16mm | 32mm | 20mm | 38mm | 20mm | 50mm | 22mm | 57mm | 30mm | 75mm | 35mm | 80mm | 50mm | 80mm | 50mm |

| Stainless Steel | 22mm | 12mm | 25mm | 15mm | 30mm | 16mm | 40mm | 18mm | 45mm | 24mm | 60mm | 25mm | 75mm | 50mm | 80mm | 45mm |

| Aluminum | 16mm | 10mm | 20mm | 12mm | 22mm | 12mm | 30mm | 15mm | 35mm | 18mm | 45mm | 25mm | 50mm | 25mm | 80mm | 45mm |

| Brass | 16mm | 10mm | 20mm | 12mm | 22mm | 12mm | 30mm | 15mm | 35mm | 18mm | 45mm | 25mm | 50mm | 25mm | 80mm | 45mm |

| Attention:Above technical parameter comes from LGK and Hypertherm website, Contains exaggerated elements, cannot take as the rule of adopting suitable power,please contact us ask for the exact suitable schemes |

||||||||||||||||

Driving System: Big power servo motor with reducer can not only offer the high power to drive machine working on fast speed, also offer the highest working precisions.

Big Round Wheel Support: Equipped with big round wheel support system, specialized for the big heavy Round pipe processing.

Transmission System: Hihg precision grinding rack add imported YYC perfect guild offer best working precision and longer service life, help machine process complex products on best accurancy.

Distribution Box: Professional industrial distribution box, all the electrical parts, and control card.etc be installed well, perfect connect design let all the parts work well together, dust proofing is great, and can also Protect against electromagnetic interference.

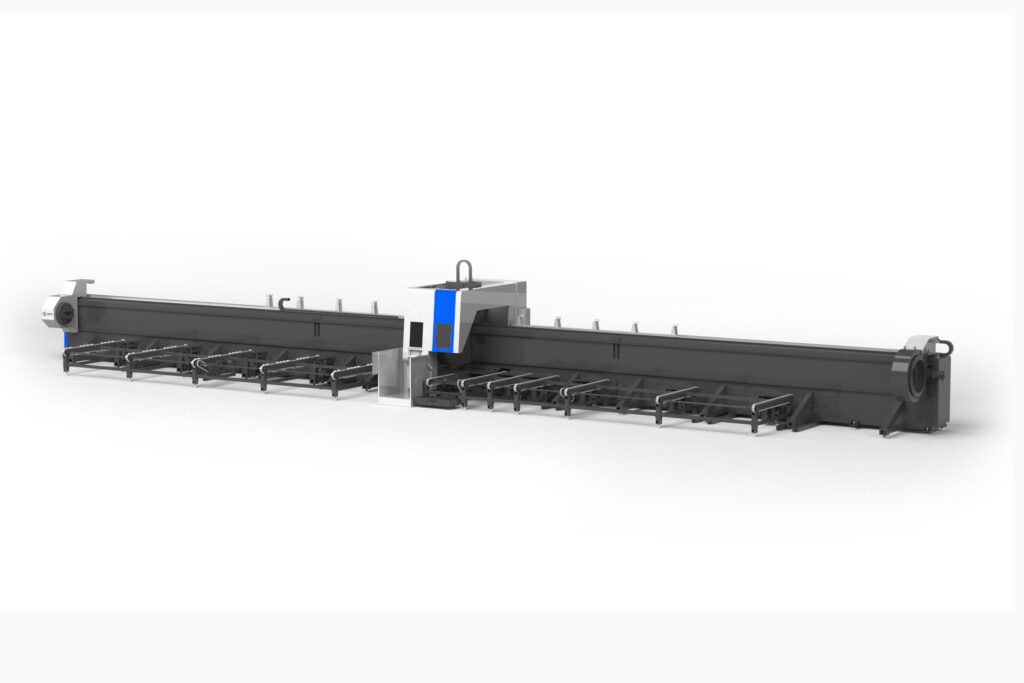

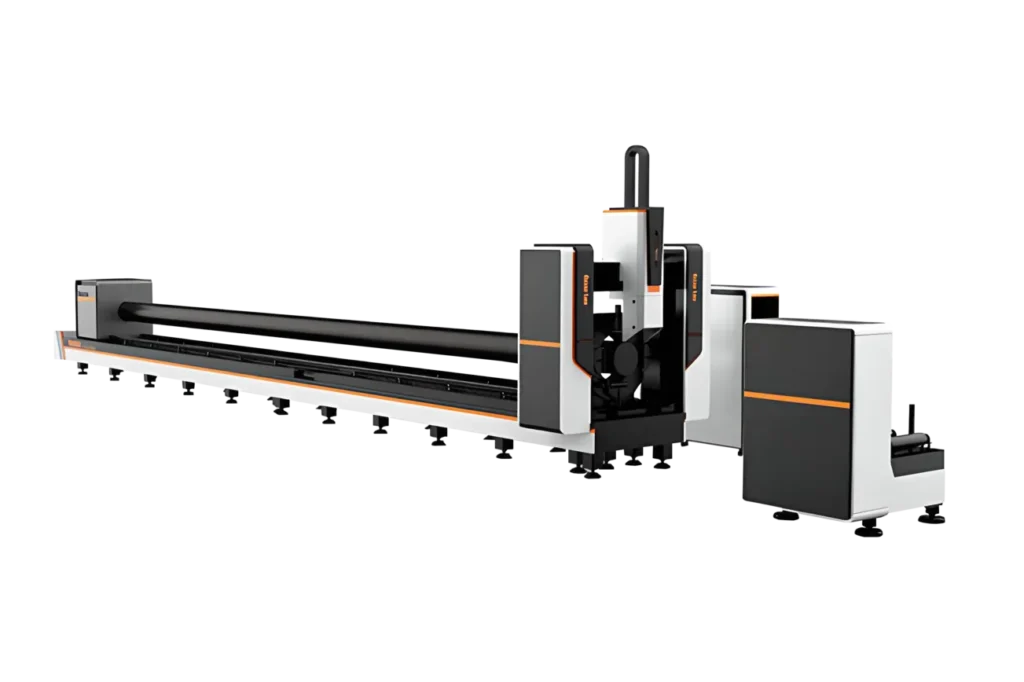

Related Machine Pictures

Applicable Industry

With superior cutting processes and results, our types of equipment, the round pipe plasma cutter, is widely used in many different industries, such as the Oil-gas Industry, New Energy Industry, Elevator industry, factory bulding Industry, City building Industry, pipe processing industry, and many other areas that required metal cutting solutions.

Oil-Gas Pipeline

New Energy Industry

Elevator

Factory Building Industry

City Building Industry

Pipe Process Industry