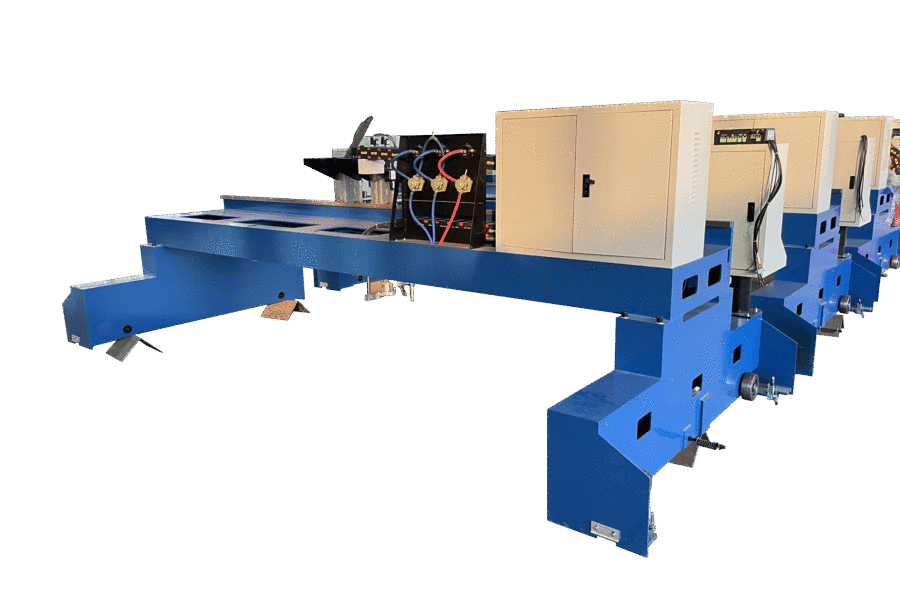

Heavy-Duty Gantry Plasma Cutting Machine | Advanced Metal Cutting with Flame Option

Discover our gantry plasma cutting machine, perfect for large and thick metal plates. Capable of cutting up to 300mm with a flame option, and can be equipped with a rotary axis for tube cutting. Built to last in tough environments

High-Performance Gantry Plasma Cutting Machine for Thick Metal Plates

Model: LT3080-PG

Working area: 2200*6000mm(3000*6000mm, 3000*12000mm, ,2500*12000mm.etc for optional)

Support Plasma Power: LGK/Hypertherm 120A, 160A, 200A, 300A, 400A as options

Price Range: $90 00 – $850 00

Warranty time: 1 year for the whole machine

Delivery time: 7-10 workdays

Technical Support Time: Free Lifetime for All Clients

Machine Videos

Technical Parameter

| Model | LT3080-PG(LT4080-PG,LT30120-PG,LT40120-PG.etc) |

|---|---|

| Working area | 2200*6000mm (3000*6000mm,2200*12000mm,3000*12000mm.etc) |

| Controller | Fangling Controller |

| Torch Height Control(THC) mode | Automatic High sensitive THC |

| Motor driver | Leadshine servo motor |

| Plasma Source | LGK / Hypertherm 160A / 200A / 300A / 400A |

| X,Y axis transmission | P24 square guild |

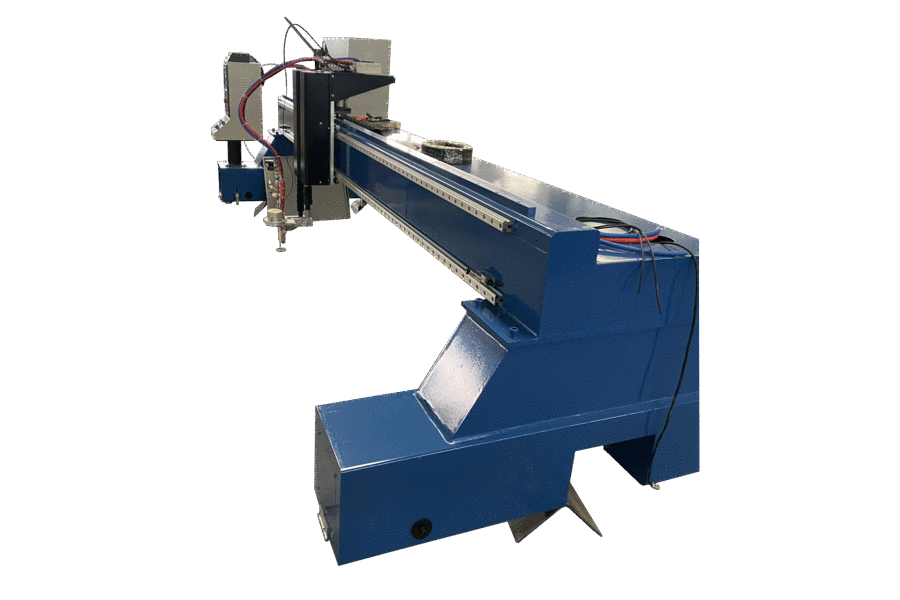

| Z axis transmission | Square guild+TBI ball screw |

| Optional Accessory | Flame Head / Bevel cutting Function |

| Cutting thickness | 0.3-50mm(add flame head can max cut over 200mm) |

| Move precision | ±0.1mm/m |

| Power | 8.5KW/H-250KW/H (Different according to plasma power) |

| Software | Fastcam / StarCAM |

| Working voltage | 380V 50HZ |

| Weight | 1800kgs |

Machine Features

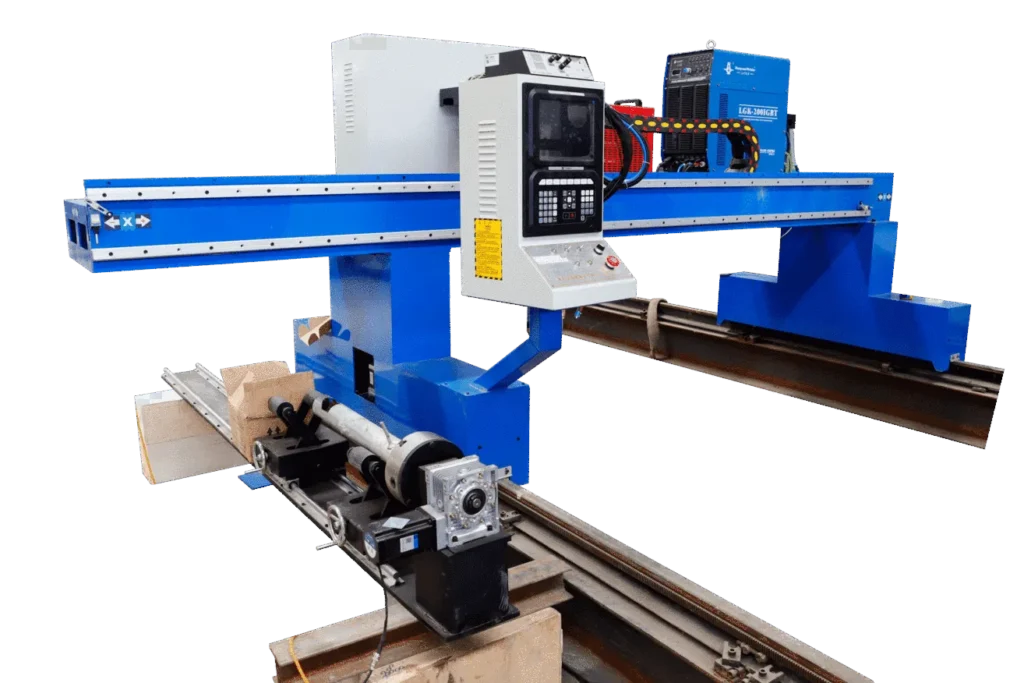

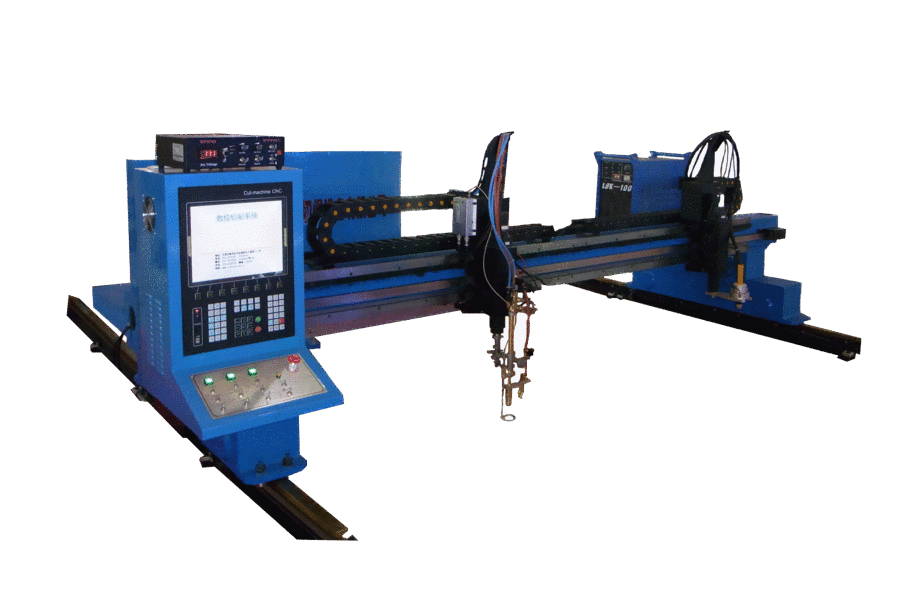

Unique Advantages: Adopt to use the Gantry styles of machine frame, the width can be 2.5m, 3m working size, the length can be not limited if customer required, usually be 6m, 8, 12m, or 24m.

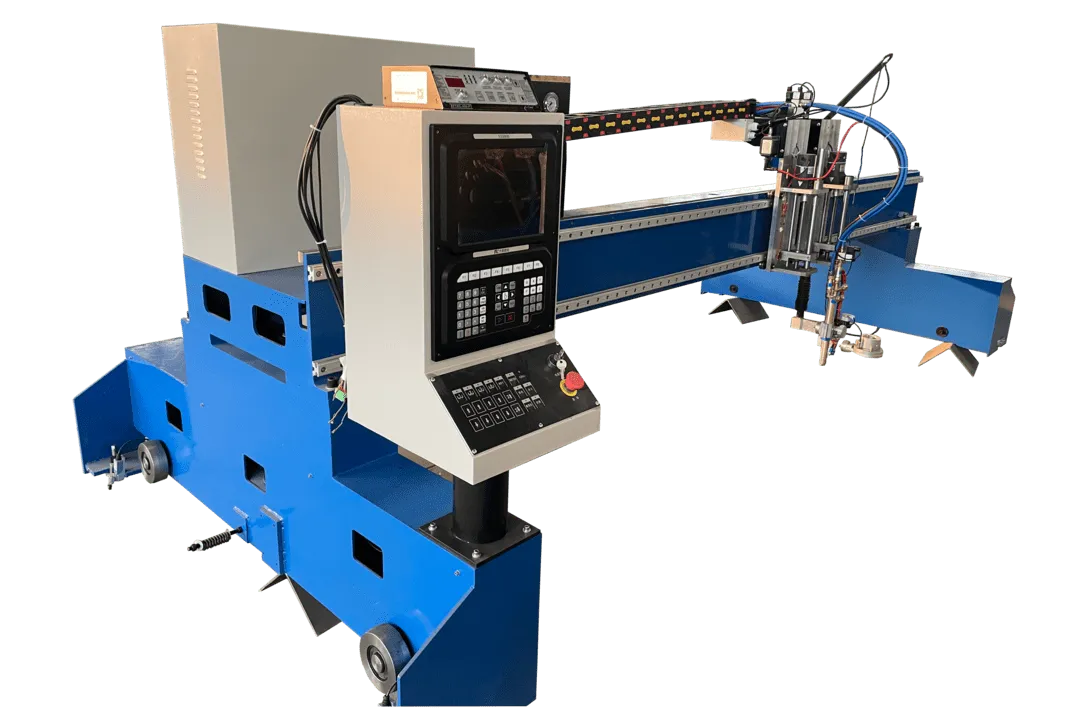

Controller: Adopt the Professional Industrial controller, can operate the whole machine working easily, usually adopt Starfire or Fangling Brand.

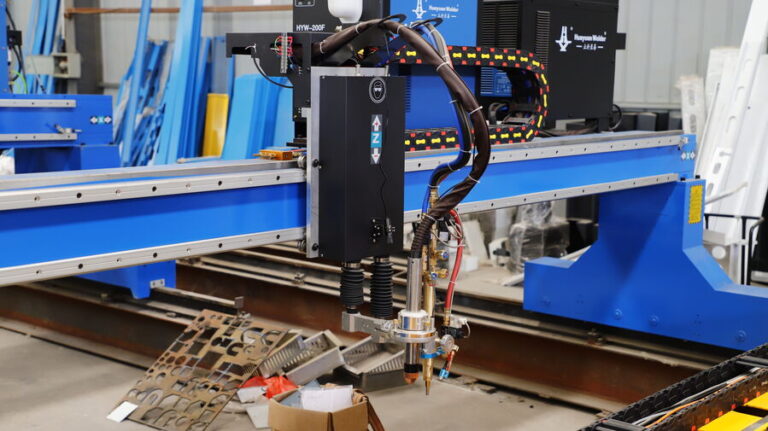

Plasma Flame Head: Excpet for the plasma torch, usually this machine will equipped with one optional flame head, Plasma usually used in cutting max 30 thickness materials, flame can cut over 30mm thickner materials.

Plasma Power Supply: Usually this machine equipped with 160A or 200A plasma power supply, also can adopt 300A or 400A. Chiller will used for cool the plasma source automatically when working.

| Different Powers' Plasma Cutting Supply Technical Parameter | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chinese LGK Plasma Power Supply | ||||||||||||||||

| Power | LGK-63IGBT | LGK-120IGBT | LGK-160IGBT | LGK-200IGBT | LGK-300HD | LGK-400HD | ||||||||||

| Working Effect | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | ||||

| Carbon steel | 25mm | 15mm | 45mm | 25mm | 60mm | 30mm | 70mm | 35mm | 100mm | 0.3-50mm | 120mm | 1-60mm | ||||

| Stainless steel | 20mm | 12mm | 36mm | 20mm | 48mm | 24mm | 56mm | 28mm | 80mm | 40mm | 95mm | 48mm | ||||

| Aluminum | 15mm | 9mm | 27mm | 15mm | 36mm | 18mm | 42mm | 21mm | 60mm | 30mm | 72mm | 72mm | ||||

| Brass | 15mm | 9mm | 27mm | 15mm | 36mm | 18mm | 42mm | 21mm | 60mm | 30mm | 72mm | 72mm | ||||

| American Hypertherm Plasma Power Supply | ||||||||||||||||

| Power | Powermax45 SYNC | Powermax65 SYNC | Powermax85 SYNC | Powermax105 SYNC | Powermax125 | MAXPRO200 | XPR300 | HPR400XD | ||||||||

| Working Effect | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut |

| Carbon Steel | 29mm | 16mm | 32mm | 20mm | 38mm | 20mm | 50mm | 22mm | 57mm | 30mm | 75mm | 35mm | 80mm | 50mm | 80mm | 50mm |

| Stainless Steel | 22mm | 12mm | 25mm | 15mm | 30mm | 16mm | 40mm | 18mm | 45mm | 24mm | 60mm | 25mm | 75mm | 50mm | 80mm | 45mm |

| Aluminum | 16mm | 10mm | 20mm | 12mm | 22mm | 12mm | 30mm | 15mm | 35mm | 18mm | 45mm | 25mm | 50mm | 25mm | 80mm | 45mm |

| Brass | 16mm | 10mm | 20mm | 12mm | 22mm | 12mm | 30mm | 15mm | 35mm | 18mm | 45mm | 25mm | 50mm | 25mm | 80mm | 45mm |

| Attention:Above technical parameter comes from LGK and Hypertherm website, Contains exaggerated elements, cannot take as the rule of adopting suitable power,please contact us ask for the exact suitable schemes |

||||||||||||||||

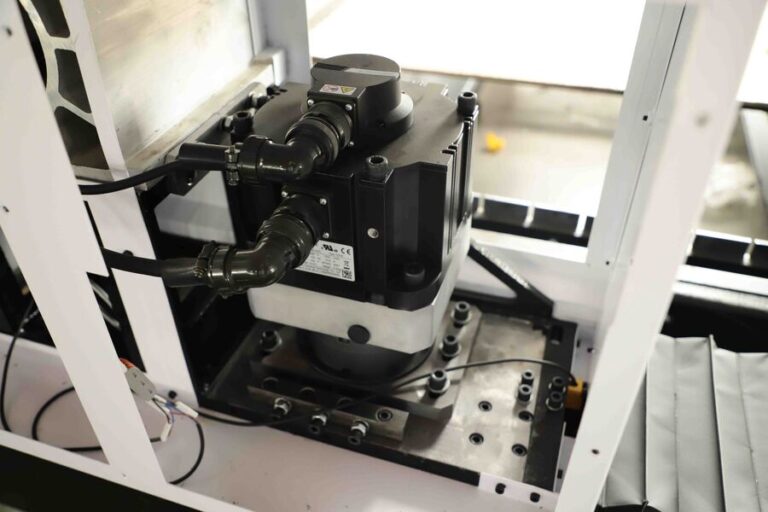

Driving System: Big power servo motor with reducer can not only offer the high power to drive machine working on fast speed, also offer the highest working precisions.

Transmission System: Equipped with P24 railway guild and helical rack system, has a more stronger support function

Strong Chain: Used to protect the related wires, water pipe, fiber wire.etc

Optional Rotary: if customer has some round pipe materials need cut, can add this rotary parts. suitable for cutting some round pipe timely.

Related Machine Pictures

Applicable Industry

With superior cutting processes and results, our types of equipment, the Plasma cutter, is widely used in many different industries, such as the Advertising Industry, Automobile Manufacture Industry, Gym Equipment Industry, Machine Manufacturing Industry, Medical Equipment Industry, Sanitary Tools Industry, Sheet Metal Cutting Industry, Steel Structure Industry, Steel-Wood Furniture Industry, Tower Industry, and many other areas that required metal cutting solutions.

Aerospace Industry

New Energy Industry

Machine Manufacturing Industry

Sheet Metal Cutting Industry

Gym Equipment Industry

Steel-Wood Furniture Industry

Sanitary Tools Industry

Medical Equipment Industry

Automobile Manufacture Industry

Handicraft Industry