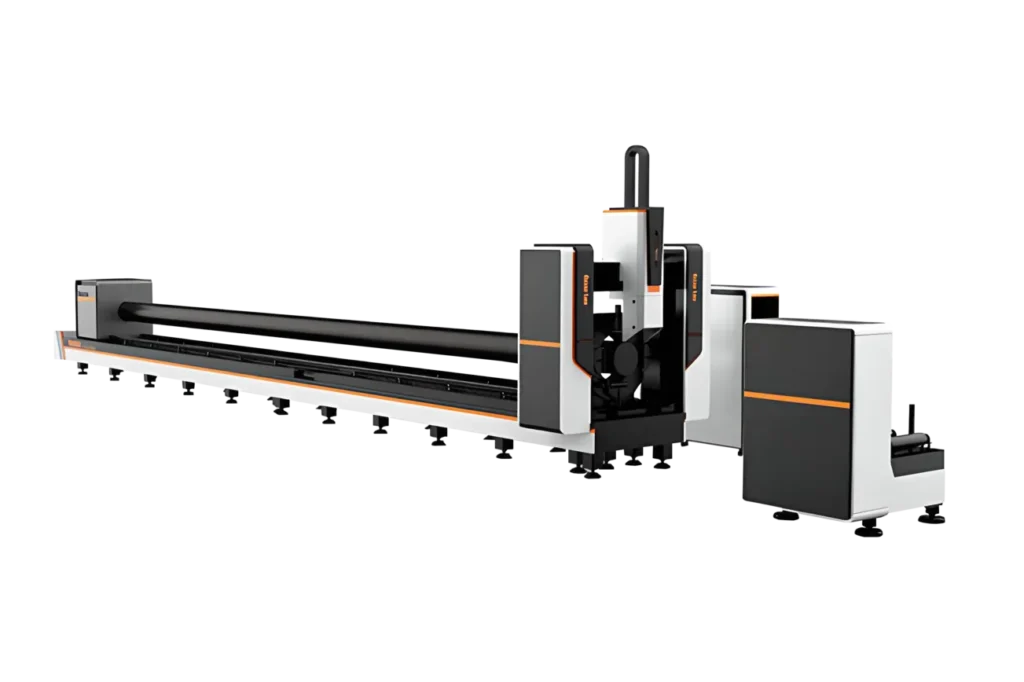

Heavy-Duty Three Chucks Fiber Laser Tube Cutter Machine | Best Tube Laser Cutting Solution

Explore our heavy-duty fiber laser tube cutter machine, designed for producing over 3m length,big diameter finished products of round, square, H-beam,V-shape tube.etc.

Large Fiber Laser Tube Cutting Machine for Round, Square, and H-Beam Tubes

Model: LT35120-FT3

Working area: Round tube:Φ20-Φ350mm,Square tube:□20-□350mm

(Φ40-Φ520mm,Φ40-Φ620mm as options)

Support Laser Power: 3kw, 6kw,12kw

Price Range: $30 00 – $155 000

Warranty time: 1 year for the whole machine

Delivery time: 25-40 workdays

Technical Support Time: Free Lifetime for All Clients

Machine Videos

Technical Parameter

| Mode | LT35120-FT3 |

|---|---|

| Laser Power | 3kw-12kw |

| Effective cutting diameter of tube | Round tube:Φ20-Φ350mm,Square tube:□20-□350mm (Φ40-Φ520mm,Φ40-Φ620mm as options) |

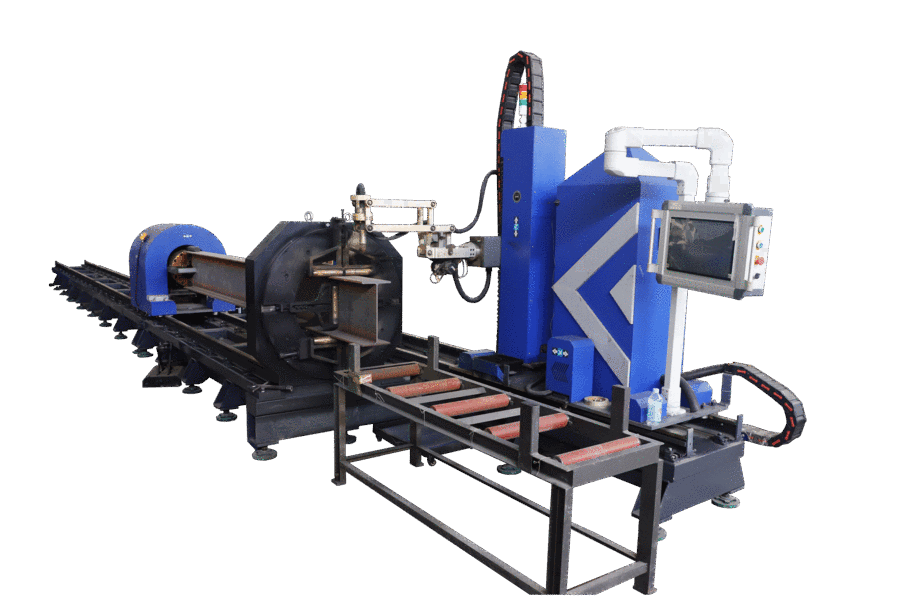

| Applicable Tube Materials | Round Tube, Square tube, H-type steel, V-type steel, I-shape steel.etc |

| Support Loading system | Auto loading system, Servo support system |

| Positioning accuracy | ±0.05mm |

| Chuck maximum speed | 60r/min |

| Maximum acceleration | 0.6G |

Machine Features

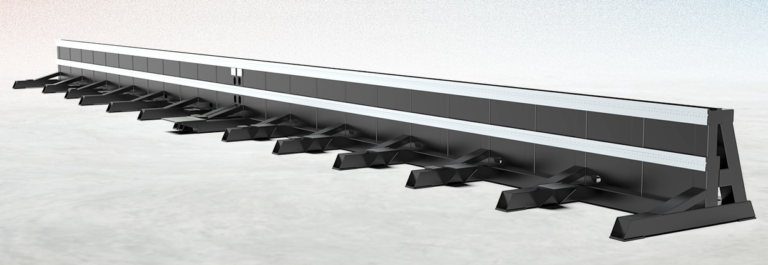

Unique Advantages: Three Chucks, slide-style heavy-industry laser tube cutting machine, widely used in processing big-long size various tube, pipe cutting. The stable working effect and strong cutting functions let it become the boss of tube cutting industry.

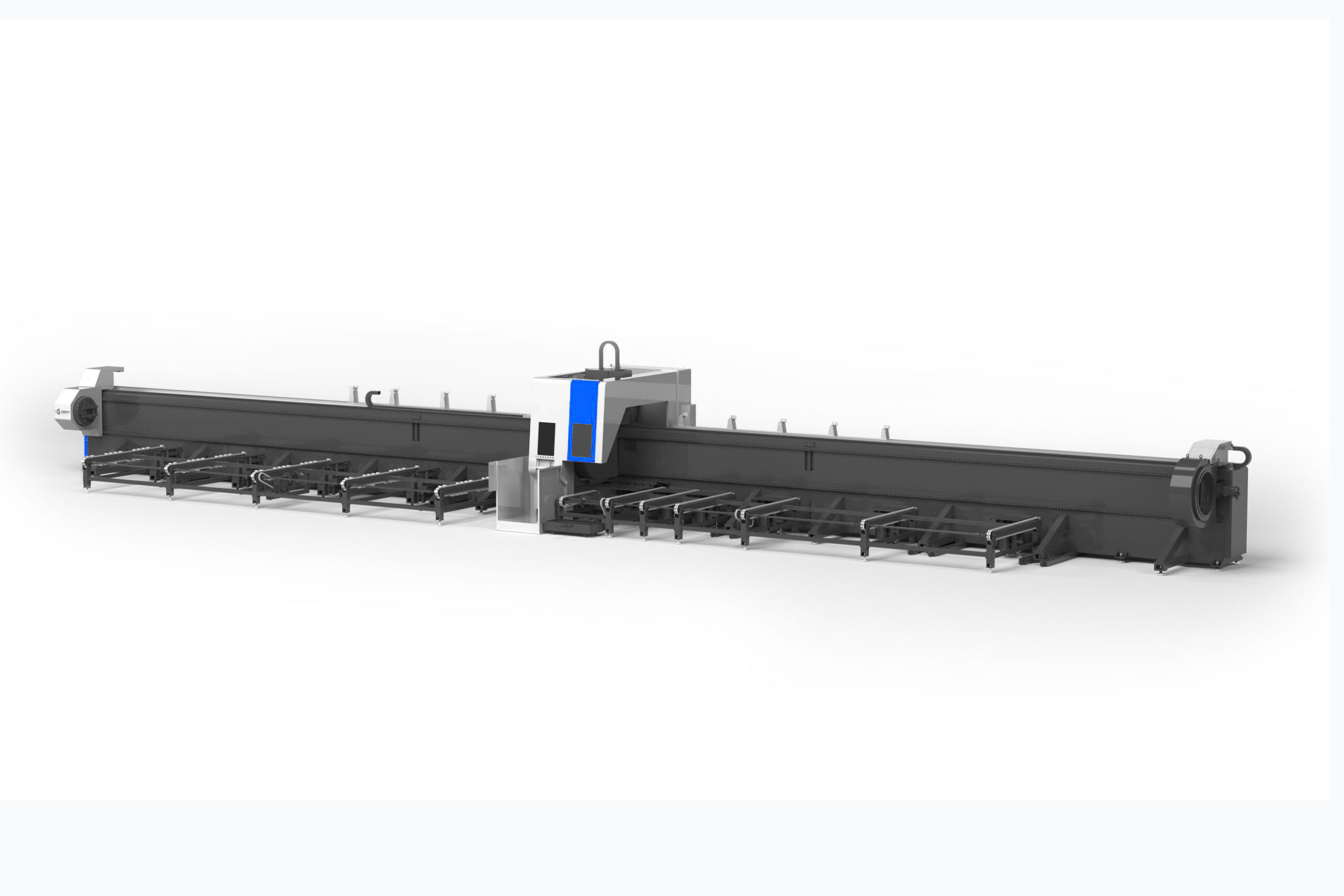

Plate and tube composite welded bed: The use of structural dynamic design principles, the use of high-quality raw materials welded, after de-stressing annealing for roughing the second vibration aging treatment, large-scale gantry milling machine precision machining. Ensure that the guide surface and rack surface one-time processing molding, to ensure the accuracy of the bed body of high intrinsic frequency, vibration damping performance is good, high-speed operation under the effective reduction of vibration; to ensure that the machine’s operating accuracy and service life.

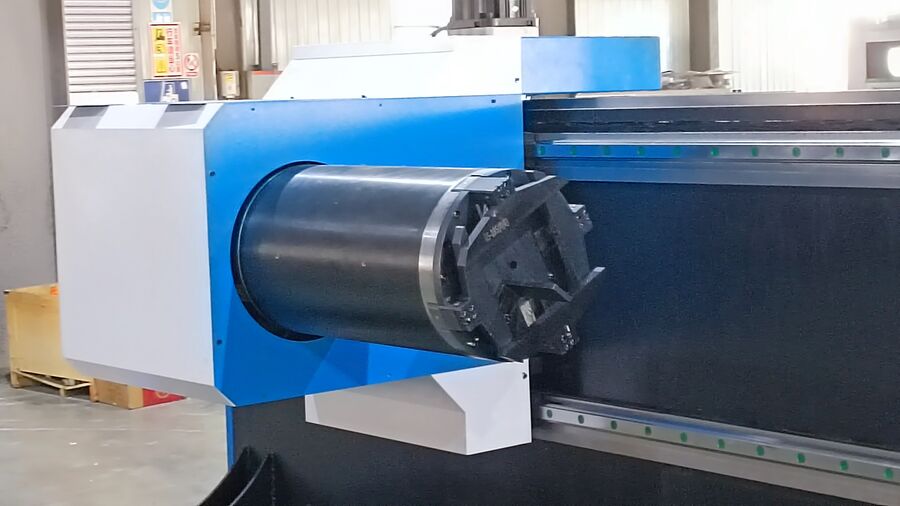

Professional full pneumatic chuck: Precise position control and torque control to ensure that thick tubes will not come loose and thin tubes will not be deformed Square and round holes design, stronger throughput capacity Clamping force can be intelligently adjusted for different types of tubes Processing needs Full-stroke clamping range without manual adjustment Eight-cylinder structure, twice the clamping force of ordinary chucks Precision grinding gear drive, stronger power, higher efficiency, high dust-proof level and greater stability.

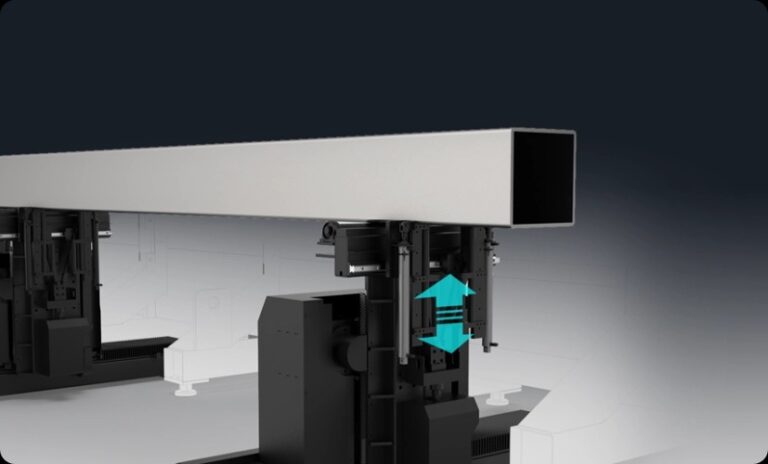

Servo-following support system: Semi-automatic loading of a single pipe, with real-time height adjustment according to the height of the pipe as it rotates.

Achieve perfect support during the cutting process

Strong load-bearing support, the overall 12-meter loading to meet the maximum weight of pipe lifting up to 1150KG.

Fiber Laser Power Supply: Perfect Max fiber laser power supply, usually adopt to use the 3kw, 6kw, or 12kw according to the materials thickness and working efficiency.

Servo Follower Downfeed: Applicable to different lengths of pipe automatic discharging, discharging high efficiency, pipe cutting and punching completion of the pallet automatically hold to prevent the pipe directly fall, convenient for the whole pipe discharging

Applicable Industry

With superior cutting processes and results, our types of equipment, the metal laser cutter, is widely used in many different industries, such as the Advertising Industry, Automobile Manufacture Industry, Gym Equipment Industry, Machine Manufacturing Industry, Medical Equipment Industry, Sanitary Tools Industry, Sheet Metal Cutting Industry, Steel Structure Industry, Steel-Wood Furniture Industry, Tower Industry, and many other areas that required metal cutting solutions.

Aerospace Industry

New Energy Industry

Machine Manufacturing Industry

Tube Cutting Industry

Gym Equipment Industry

Steel-Wood Furniture Industry

Sanitary Tools Industry

Medical Equipment Industry

Automobile Manufacture Industry

Handicraft Industry