Plasma Cutting Machine Recommendation Report

Plasma Cutting Machine

As a sales engineer with 20 years of experience in the production and sales of plasma cutting machines in China, this report aims to provide recommendations and guidance on plasma cutting machines for individual users and overseas agents. The report introduces the working principles and main classifications of plasma cutting machines, analyzes the advantages, applicable scenarios, and price ranges of various types of equipment, and provides corresponding recommendation plans for different types of users (from beginners to industrial customers, as well as specific professional fields). Additionally, we will discuss current trends in plasma cutting technology and provide a product recommendation table categorized by function, industry, and price level for quick reference and comparison. The content is clearly structured and easy to understand, making it suitable for direct forwarding to customers.

1. Principles and Classification of Plasma Cutting Machines

Working Principle: Plasma cutting is a process that uses a high-velocity jet of high-temperature ionized gas (i.e., plasma) to cut electrically conductive metals. When an arc is formed between the electrode and the workpiece, it heats the gas into a plasma state (^1). The plasma arc reaches extremely high temperatures, instantly melting the metal. The molten metal is then blown away from the cut by the high-speed gas stream, achieving the cutting action (^2). This process efficiently cuts various conductive metal materials, including steel, aluminum, copper, and their alloys.

Equipment Classification: Based on structure and application scenarios, plasma cutting machines can be broadly classified into the following categories:

-

Handheld Plasma Cutting Machine: Also known as portable machines. They consist of a torch and power supply, operated manually. Suitable for on-site repairs, DIY, etc. Compact, lightweight, and flexible. Typically lack CNC systems, relying on manual operation. Relatively low cost, ranging from a few hundred to a few thousand USD.

-

CNC Plasma Cutting Machine: Uses Computer Numerical Control (CNC) for automated control of torch movement, enabling precise cutting. Common CNC plasma machines are further subdivided by structure: portable CNC machines, benchtop/gantry tables, gantry-type machines, pipe intersecting cutting machines, and robot-integrated systems (^3). These types will be detailed below. CNC plasma cutters are an upgrade over handheld machines, offering higher precision, automation, and production efficiency.

2. Advantages, Application Scenarios, and Pricing of Plasma Cutting Machine Types

Different types of plasma cutting equipment have distinct characteristics and suitable applications. Below are the advantages, typical application scenarios, and approximate price ranges for the main categories:

-

Portable CNC Plasma Cutting Machine: A small, lightweight CNC cutter, often with a cantilever structure. Advantages include portability, compact size, small footprint, flexible installation, and low manufacturing cost (^4). Ideal for on-site construction, farm repairs, small workshops, and other scenarios requiring high mobility. Some models offer both plasma and optional flame cutting, providing good value. Costs significantly less than larger machines for similar cutting capabilities. However, due to the single-sided cantilever design, rigidity is relatively lower, potentially leading to vibration and deformation during high-speed cutting, with limited transverse cutting width (^5). Typical cutting area is around 1.2 meters, suitable for medium-thin plate cutting. Price range: USD $3,000-$8,000 (lower for entry-level configurations) (^6).

-

Benchtop CNC Plasma Cutting Machine: Also known as worktable plasma cutters. Integrate the cutting platform and drive system on a fixed frame. The integrated design facilitates setup and movement (^7). Compact footprint but relatively limited cutting area; common sizes include 4×4 ft, 4×8 ft, etc., suitable for cutting small to medium-sized plates (^8). Widely used in small equipment workshops, educational labs, and sign/advertising fabrication. Advantages: higher precision, user-friendly interface, capable of fast and accurate cutting of complex shapes (^9). Pricing: Economical CNC equipment, typically USD $4,000-$15,000 (varies based on cutting area and plasma power).

-

Gantry-type CNC Plasma Cutting Machine: Utilizes a double-side driven gantry frame structure with crossbeam support on both sides, offering good rigidity and stable operation. Its main advantage is the capability for large-format metal plate cutting, with spans typically ranging from 3~10 meters or even larger (^{11}). Suitable for heavy industrial applications like shipbuilding, structural steel, and engineering machinery. Can be equipped with both plasma and flame torches to handle materials of varying thicknesses. Requires significant factory space and proper foundation installation due to its large size. Drive types: single-side (simpler, limited span) or dual-side (higher synchronization requirement, suitable for large spans/heavy loads). Relatively expensive, generally USD $10,000-$50,000 or higher (depends on size and plasma power). High cutting efficiency, strong thick-plate capability (can cut steel up to several tens of mm thick), highly valuable in heavy industry.

-

Pipe-Dedicated Plasma Cutting Machine: Also known as pipe intersecting cutting machines. Specifically designed for cutting and profiling metal pipes (round, square, structural shapes). Equipped with a rotating chuck and CNC axes for precise pipe positioning, enabling cutting of pre-set holes, bevels, and intersecting contours. Widely used in structural steel, pipeline engineering, petrochemical piping, etc., for efficient pipe notching, cutting, and weld prep. Some models support both plate and pipe cutting (plate-pipe combo machines), enhancing versatility. Advantages: Improved pipe processing precision and efficiency, replaces manual layout cutting, ensures accuracy of complex joints. Professional-grade pricing, roughly USD $15,000-$30,000 (varies by number of axes and processing diameter range).

-

Robot-Integrated Plasma Cutting System: Involves mounting a plasma torch onto a large industrial robot for multi-axis, 3D cutting. Offers high flexibility and automation, capable of cutting complex curved surfaces and trimming tasks. Examples: Trimming stamped parts or cutting spatial curves in automotive manufacturing; notching and angle cutting of profiled steel in structural steel/heavy industry. Key advantages: Faster cutting speeds (can be multiples of manual torches, meters per minute); Wide material thickness range (thin to thick plate); High processing flexibility (handles diverse shapes on one system); Significantly improved safety (removes operators from high-heat hazards during thick-plate cutting). Main characteristics: High system cost and complex programming, typically only affordable/utilizable by large factories. Robot-integrated systems are expensive, often starting from USD $50,000+, with high-end configurations reaching hundreds of thousands.

Different plasma cutting equipment types have unique features. Businesses and users should select the appropriate model based on their processing scale, material thickness range, and budget. For example, entry-level small CNC plasma cutters cost around $4,000, while industrial-grade large CNC cutting tables average around $20,000 (2025 market data).

3. Recommended Plasma Cutting Solutions for Different Users

Different users should prioritize different factors when selecting plasma cutting machines due to varying application needs and budgets. Below are recommendations for beginners/individual users, small workshops, medium/large industrial clients, and clients in specific professional fields, along with key performance parameters to consider.

1. Beginners/Individual Users (DIY, Light Sheet Metal, etc.)

Demand Characteristics: Typically used for DIY projects, hobby creations, or small-batch light sheet metal work, mainly cutting thin to medium thickness metals (generally ≤ 8mm). Emphasize ease of use, low cost, safety, reliability, and compact size. Power compatibility (e.g., support for household 110V/220V) is crucial for use in home garages or small workshops.

Recommendation: For beginners, a Handheld Plasma Cutting Machine is an economical choice. Compact, lightweight, and utilizing high-frequency inverter technology for stable arc ignition. Simply connect to compressed air and single-phase power (many models support 110V/220V dual voltage) for easy cutting of stainless steel, carbon steel, etc. Cutting current is continuously adjustable for different thicknesses. Simple and intuitive operation, ideal for DIY enthusiasts. Note: Cutting relies on manual skill, precision is limited, but sufficient for general trimming and simple cutting tasks.

For users with a higher budget seeking improved precision, consider an entry-level Small CNC Plasma Cutting Table (e.g., 4×4 ft / ~1.2×1.2m table size). Equipped with a 60~65 Amp plasma power source, it can cut 6-8mm carbon steel (^{20^\circ}). Priced around a few thousand USD, offering good value. The CNC system supports USB file import and automatic nesting, significantly improving cut quality and repeatability over manual operation. Ideal for personal workshops making metal art, signs, and models. Most Chinese CNC plasma systems support Chinese/English interface switching (^{21^\circ}). Power-wise, many small machines are designed for export, compatible with both 110V and 220V (^{22^\circ}), eliminating home circuit compatibility concerns.

2. Small Workshop Users (Small-Medium Batch Production)

Demand Characteristics: Workshops like sheet metal shops, mechanical repair shops, agricultural machinery factories. Typically need medium-batch plate cutting, handling thicknesses from thin to medium plate (e.g., 1-20mm). Focus on equipment stability, processing efficiency, low maintenance costs, and long operational hours. Require a certain level of automation and precision for quality assurance, while being cost-sensitive.

Recommendation: CNC Benchtop Plasma Cutters or Small Gantry Plasma Cutters are ideal. Selection depends on cutting area needs: If typical workpiece size is small (e.g., ≤1.5m width), a Benchtop CNC Plasma Table (e.g., 4x8ft or 5x10ft) is recommended. Compact, using gantry dual-drive or cantilever design with stepper/servo motors, capable of cutting at thousands of mm/min (^{23^\circ}). Cutting precision around ±0.5mm, sufficient for general fabrication. Ensures consistent dimensions for batch production. For plasma power, a ~100A air plasma source is suitable for most needs (penetrates ~15mm carbon steel (^{20^\circ})). For occasional thicker cuts, consider models with optional oxy-fuel flame cutting capability (handles >50mm plate).

Crucially, prioritize models with Servo Drive Systems (^{26^\circ}). If budget allows, servo motors offer smoother, more precise motion control than steppers, no step loss at high speeds, and higher positioning accuracy. Servo systems maintain repeatability over long runs, improving yield. While adding some cost, they enhance long-term production efficiency and stability, offering good ROI (^{26^\circ}). Overseas agents should also consider control system software language and after-sales support. Most Chinese CNC systems offer English interfaces; common nesting software (e.g., FastCAM, SheetCAM) have multilingual versions (^{21^\circ}). Power: Small CNC machines typically require 3-phase power (e.g., AC 380V). Manufacturers can provide custom transformers or electrical configurations for regions using single-phase 220V or different industrial voltages.

3. Industrial-Grade Customers (Large Format, Heavy Industrial Applications)

Demand Characteristics: Large manufacturers, steel processing centers, shipyards, heavy machinery plants. Require large-format, high-thickness metal cutting, often handling plates >20mm thick or large workpieces. Demand extremely high equipment stability, efficiency, functionality, and 24/7 operation capability. Need high-speed piercing for thick plates and system integration into production lines. Cutting precision/quality is critical; high-end users seek plasma quality approaching laser. Require compliance with environmental and safety standards (dust/fume extraction).

Recommendation: Large Gantry-type CNC Plasma Cutting Machines are the primary choice. Gantry structure enables wide cutting ranges (e.g., 3m x 12m+), processing full sheets without segmentation. Equipped with high-power plasma sources (e.g., 200A+) to cut steel up to 30mm+ thick (^{27^\circ}). High-end plasma systems (e.g., Hypertherm) use fine plasma technology for high-quality, near-vertical cuts on thick plate, reducing secondary processing (^{13^\circ}). For plates >50mm, add oxy-fuel cutting capability for tasks beyond plasma range, enabling multi-process use.

Industrial plasma cutting must focus on High-Speed Piercing and production cycle time. Piercing is often the bottleneck for thick plates. New high-end systems significantly improve piercing via optimized arc energy and gas control, drastically increasing speed and reducing spatter/arc instability. For example, advanced piercing can penetrate 20mm steel in seconds with good quality, greatly improving efficiency for industries like shipbuilding/bridge fabrication needing numerous piercings.

Industrial clients also need Automation Integration. Modern high-end CNC plasma systems feature interfaces to link with other production line elements (material handling, part sorting) for streamlined workflow. Multilingual software and remote diagnostics are vital (English is standard, Spanish/Russian interfaces often available). Manufacturer training and after-sales support (English-speaking tech support, easy software updates) are key considerations. Industrial equipment is a major investment but offers high returns through automated cutting: improved material utilization, production efficiency, consistent quality, and reduced labor, providing competitive advantage in heavy industry.

4. Specialized Field Customers (Pipe Processing, Automotive, Structural Steel, Signage, etc.)

Specialized customers have specific needs requiring tailored cutting solutions. Recommendations for key fields:

-

Pipe Cutting (Piping/Structural Steel Industry): For companies focused on pipe processing (structural steel, pipeline installers), recommend Pipe-Dedicated CNC Plasma Cutters or Plate-Pipe Combo Machines. Equipped with rotating chucks for slotting, hole cutting, and beveling on round/square tubes. Enables precise pipe intersecting cuts (e.g., H-beam web holes, pipe-to-pipe connections) in one step, ensuring accurate joints. Combo machines maximize equipment utilization. Key specs: Max pipe diameter and wall thickness capability. Typical mid-range machines handle pipes up to ~500mm diameter and ~20mm wall thickness. Ensure control software includes specialized pipe profiling modules for automatic trajectory generation based on pipe diameter and intersection angles. User-friendly interfaces are essential.

-

Automotive Manufacturing: Involves significant 3D curved parts and high-precision cutting (body panel trimming, chassis hole cutting, hydroformed part windowing). Robot Plasma Cutting Systems are highly suitable. Mounting the torch on an industrial robot arm enables flexible 6-axis cutting of complex workpieces. Robots can cut at any spatial angle, achieving spatial curves impossible with 2D machines, meeting precision trimming requirements. Compared to laser robots, plasma offers lower investment, faster cutting speeds (meters per minute), and a wider thickness range (thin to thick plate, depending on power). A good choice for automotive parts requiring medium precision but high efficiency/cost-effectiveness (e.g., truck frame holes, construction vehicle cab components). Focus on robot offline programming software language support and features like anti-collision sensors and automatic height control (THC) for consistent quality and safety.

-

Structural Steel & Heavy Fabrication: Require large/thick plate cutting and profiled part cutting. Recommend High-Power Gantry Plasma/Oxy-Fuel Cutting Machines as core equipment. Opt for Plasma + Flame Hybrid Configuration: Both torches on one gantry. Plasma for fast cutting of <30mm steel; Flame for thicker plates (>50mm) or large bevels. CNC programs automatically switch processes based on thickness. Plasma offers higher efficiency and better precision than manual gas cutting for tasks like beam/column plate cutting or bridge steel. Fine plasma systems produce near-vertical cuts, quality close to laser at lower cost, reducing grinding. Advanced CNC systems can control plasma torch for bevel cutting (V, Y, K types), greatly boosting productivity in steel/shipbuilding. Overseas buyers should ensure suppliers offer complete dust/fume extraction systems and electrical designs meeting local safety standards (e.g., CE), as heavy plasma cutting generates significant smoke and arc glare.

-

Signage & Decoration Industry: Primarily process thin stainless steel, galvanized steel, and aluminum sheet, requiring fine cuts with minimal distortion. Users often compare plasma vs. laser. For budget-conscious users needing decent precision, consider Small High-Precision Plasma Cutters. Benchtop machines with fine plasma power supplies and small nozzles produce narrow kerfs and small heat-affected zones (^{13^\circ}). Fine plasma edge quality approaches laser at a fraction of the laser system cost (^{35^\circ}), offering high value for cutting letters, signs, etc. Some manufacturers offer Laser/Plasma Hybrid Cutters for this industry. Integrate a low-power fiber laser head and plasma torch on one machine: Use laser for intricate details/very thin materials (burr-free small holes, sharp corners); Switch to plasma for thicker structural parts (>3mm stainless/aluminum bases) for speed and cost advantage. Hybrid systems enable sign makers to handle diverse tasks while controlling investment. Ensure the hybrid control system seamlessly supports both processes, with comprehensive language interfaces and technical support for overseas users.

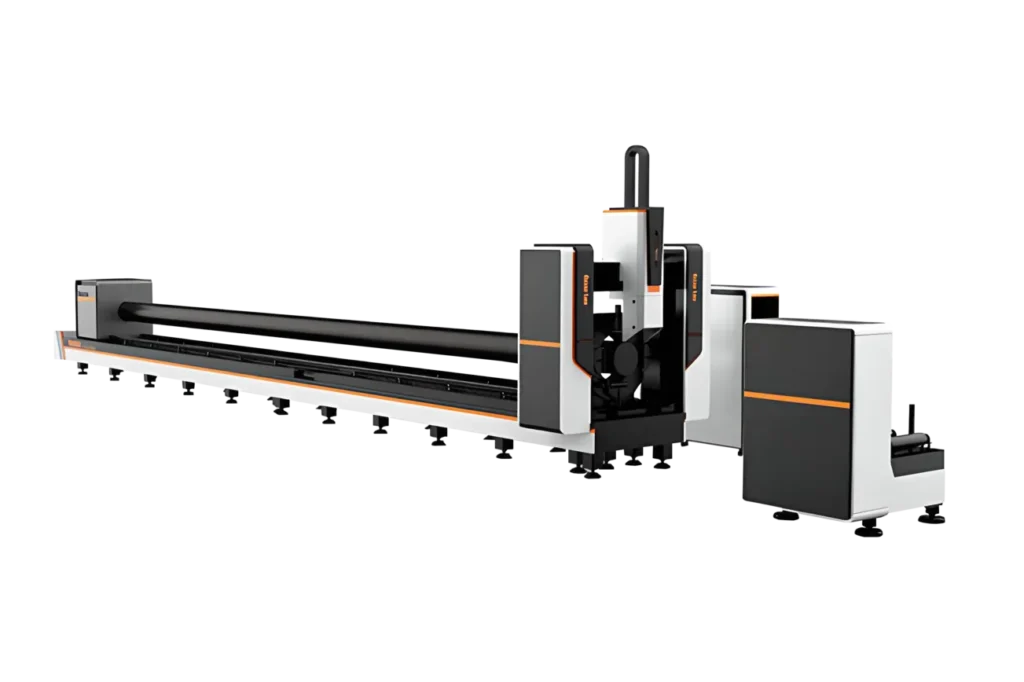

Figure: 5×10 ft Gantry CNC Plasma Cutting Machine (Model STP1530R), equipped with Hypertherm (USA) plasma power source for sheet metal cutting and a 4th axis rotary device for metal pipe cutting (^{36^\circ}). This plate-pipe integrated equipment is ideal for structural steel and pipeline engineering, improving processing flexibility and efficiency. For overseas agents, this "multi-purpose" machine is highly attractive, demonstrating higher ROI to end customers.

4. Trends in Plasma Cutting Technology

Plasma cutting technology has seen significant advancements in control systems, power source performance, and process integration, aiming for higher efficiency, better cut quality, and broader application. Key trends:

-

High-Frequency Inverter & Digital Control: Modern plasma cutters widely use HF inverter power supplies with digital control for finer output regulation and faster response (^{19^\circ}). HF inverters reduce size/weight and provide stable high-frequency arc ignition, crucial for stable arcs on thin sheets and small circles (^{20^\circ}). CNC systems enable real-time communication between plasma power source and controller for intelligent current/voltage adjustment during cutting. HF inverter + digital control enhances precision, reliability, and suppresses HF interference, making them ideal for CNC automation. Includes energy-saving designs (e.g., soft-switching inverters) reducing energy consumption per cut.

-

High-Speed Piercing Technology: Addresses the thick-plate piercing bottleneck. New technology rapidly pierces thick plate by boosting initial arc power and optimizing gas flow, then automatically switching to normal cutting mode. Significantly reduces piercing time. E.g., some high-end systems pierce 20mm steel in <2 seconds (^{Page 6}). Crucial for jobs with many piercings (shipbuilding, bridges). Often coupled with anti-spatter technology (special gas control) to blow away slag during piercing, protecting the torch nozzle and extending consumable life/improving quality. Expands plasma cutting into heavy thick-plate fabrication, narrowing the efficiency gap with lasers.

-

Servo Drives & Precision Control: Full servo-driven CNC plasma cutters are becoming mainstream in the high-end segment. Servo motors paired with high-precision ball screws or gear racks enable high-speed, smooth motion control and precise positioning even at high speeds, avoiding step loss/vibration common with steppers. This results in smoother cuts, especially on small holes or complex contours. Servo systems often feature auto-calibration and feedback (real-time position monitoring/correction) ensuring long-term repeatability. Enables high-speed marking, fine hole cutting. Although costlier, servo drive adoption is increasing in mid-range machines as prices decline, poised to replace steppers. Advanced controls add Real-Time Height Control (THC), anti-collision sensors, further boosting automation and safety.

-

Laser/Plasma Hybrid Cutting Solutions: Combine the strengths of different processes. Most notable is integrating plasma and laser cutting. Plasma excels in speed/cost for thick plates; laser is unmatched for thin-sheet precision. Fusion broadens processing range and flexibility. E.g., dual-torch systems: high-power plasma + medium-power fiber laser on one machine. The control system auto-selects laser or plasma based on material thickness: Laser for thin/high-precision areas (clean, dross-free cuts); Plasma for thick/large contours (faster severing). Applied in heavy manufacturing (mixing precision parts/large structures) and custom job shops. While currently expensive and complex, it represents a future direction of integrated cutting technology. Other explorations include plasma-waterjet combinations (using water curtain to reduce HAZ for "colder" cutting), indicating ongoing evolution. Complementing other processes expands plasma’s role in manufacturing.

5. Plasma Cutting Machine Recommendation Summary Table

The table below summarizes common plasma cutter solutions categorized by function, applicable industry, and price level for quick comparison:

| Cutting Machine Type | Applicable User/Industry | Price Range (USD) |

|---|---|---|

| Handheld Plasma Cutter (Portable Manual) |

DIY Individuals, On-site repair, Farm work (needing high mobility) (^{19}) | $200 ~ $2,000 (Entry-Level) |

| Portable CNC Cutter (Small Cantilever/Gantry) |

Small Workshops, Outdoor construction, Thin sheet cutting; Flame option for thick plate (^{5}) | $3,000 ~ $8,000 (Economy) |

| Benchtop CNC Plasma Table (Fixed Worktable) |

Sheet Metal Workshops, Education/Training, Signage/Advertising (Medium/small plate) (^{7}) | $4,000 ~ $15,000 (Econ/Mid) |

| Gantry CNC Plasma Machine (Large Dual-Drive) |

Structural Steel, Shipbuilding, Machinery Mfg. (Large format, thick industrial cutting) (^{10}) | $10,000 ~ $50,000 (Industrial) |

| Pipe-Dedicated Plasma Machine (Intersecting Cutting) |

Pipeline Engineering, Structural Steel, Metal Pipe Processing (Pipe intersecting cutting) (^{14}) | $15,000 ~ $30,000 (Professional) |

| Robot Plasma Cutting System (Multi-axis Integrated) |

Automotive Mfg., Profiled Part Processing, Aerospace/Military (Complex 3D cutting) (^{15}) | $50,000+ (High-End Custom) |

Note: The above price ranges are rough estimates. Actual prices vary based on configuration (plasma power source brand/power, control system, add-ons). Overseas procurement must consider shipping, tariffs, and local after-sales service investment.

Through this report, we see plasma cutting machines, as advanced metal cutting equipment, have evolved into a rich variety of product types, from entry-level handheld units to high-end robotic systems, meeting diverse user needs. Selection should comprehensively consider factors like material thickness, workpiece size, precision requirements, budget, and operating habits to choose the most suitable model. Key considerations include technical specs (max cutting thickness, kerf width), electrical compatibility (power voltage, control system language), and supplier after-sales support level.

Recent years show plasma technology advancing towards higher speed, precision, intelligence, and energy efficiency. New trends (HF CNC, high-speed piercing, servo control, laser-plasma hybrid) indicate further performance improvements. This will bring users higher production efficiency and superior cutting quality.

For individual users and overseas agents, we hope this report serves as a valuable reference. During actual procurement and promotion, we recommend in-depth communication with manufacturers regarding specific needs to obtain tailored technical data and demos. With correct selection and full utilization of equipment performance, plasma cutting machines will become reliable and efficient tools in various metal processing tasks, significantly enhancing your business value.

References:

- StyleCNC Blog: What Types of CNC Plasma Cutting Machines Are There?

- StyleCNC Blog: Advantages of Plasma Cutting

- StyleCNC Blog: Handheld Plasma Cutter vs. CNC Plasma Cutter Comparison

- ADH Machine Tool: Laser Cutter vs. Plasma Cutter: Which is Better?

- Alibaba Product Spec: Ultra-Light Gantry CNC Plasma Cutter QXLM-1530

- Amazon Product Desc: CNC Plasma Control System Multilingual Interface Description

- BossTables Knowledge Base: Servo Motors vs Stepper Motors in Plasma Cutting Performance

- StyleCNC Tech Doc: Plasma Power Source & Cutting Thickness Reference Table

- StyleCNC News: 2025 Plasma Cutter Price Range & Average Cost

- StyleCNC User Guide: Plasma CNC System Control Software & Nesting Software

- Laser Cutter vs. Plasma Cutter: Which is Better? – ADH Machine Tool

https://www.adhmt.com/zh/%E6%BF%80%E5%85%89%E5%88%87%E5%89%B2%E6%9C%BA%E4%B8%8E%E7%AD%89%E7%A6%BB%E5%AD%90%E5%88%87%E5%89%B2 - CNC Plasma Cutting Machine – STYLECNC

https://www.stylecnc.cn/plasma-cutter/ - Handheld vs CNC (Robotic) Plasma Cutter: Which is Right for You?

https://www.stylecnc.cn/blog/handheld-vs-cnc-plasma-cutter.html - CNC Controller System 4G Storage Space Flame Plasma Cutting Machine Controller System Motion Controller System Intelligent 100-240V for Metal Processing Advertising – Amazon.com

https://www.amazon.com/Controller-Intelligent-100%E2%80%91240V-Processing-Advertising/dp/B0B5VMH5TT - Ultra Light Gantry CNC Plasma Cutting Machine 1530 China ce Certification, 110v/220v – Buy Cnc Plasma Cutters plasma Cutting Machine plasma Cutters portable Plasma Cutter portable Cnc Plasma Cutting Machine cnc Plasma Cutter Machine cnc Plasma Cutter Single Rail plasma Iron Cutter Machine guide Rail Plasma Cutter mini Plasma Cutter Cnc cnc Plasma Cutter 1500 X 3000 cnc Plasma Portable Plasma Cutter mini Cnc Plasma Cutter Table Stainless Steel Gantry Cnc Cutting Machine Product on Alibaba.com

https://chinese.alibaba.com/product-detail/Super-light-Gantry-Cnc-Plasma-Cutting-1601513541857.html - Servo Motors vs Stepper Motors – Boss Tables | CNC Plasma Tables

https://www.bosstables.com/blog/stepper-motors-vs-servo-motors - Will Robotic Plasma Cutting Replace Manual Plasma Cutting? – OFweek Robotics Network

https://robot.ofweek.com/2020-09/ART-8321202-8500-30460642.html - Benefits and Advantages of Using Robotic Plasma Cutting – Nanjing Linghang Automation Technology

http://www.jshauto.com/hangye/67.html