Purchasing Fiber Laser Cutting Machines: Cutting Thickness is Key, How to Choose Correctly

Overview of Fiber Laser Cutting Machine Basics

A fiber laser cutting machine is a CNC device that utilizes a high-energy-density laser beam to melt and vaporize materials for high-precision cutting. Its working principle involves focusing the laser into an extremely fine spot (diameter can be less than 0.1mm), rapidly heating the material at the focal point to vaporization temperature to form a penetration hole, and continuously creating a narrow kerf along the set path to complete the cut. Due to the extremely small spot size and highly concentrated energy, fiber laser cutting machines produce narrow kerfs, small heat-affected zones, and smooth, burr-free edges, often eliminating the need for additional polishing before welding or assembly. Compared to traditional punching or plasma cutting, fiber laser cutting offers advantages such as high precision, fast speed, and excellent flexibility, making it widely used in sheet metal processing, home appliance manufacturing, automotive parts, aerospace, advertising signage, and many other fields.

When purchasing a fiber laser cutting machine, "cutting thickness" is one of the key parameters to consider. Different laser powers can effectively cut different material thicknesses, directly determining the machine’s applicable processing range and industry scenarios. If the selected machine has insufficient power, it may not cut the required material thickness; conversely, excessive power means higher costs, increased energy consumption, and potentially unused capacity in actual production. Therefore, procurement managers need to understand the common materials and thicknesses in their business and rationally select laser power based on thickness requirements. The following sections will elaborate on the relationship between fiber laser cutting machine power and cutting thickness, providing selection guidance combined with typical needs across different industries.

Relationship Between Cutting Thickness and Laser Power

The power of a fiber laser cutting machine directly affects its ability to cut different materials. Generally, higher power enables cutting of thicker plates and faster cutting speeds. However, different materials absorb laser energy and have varying cutting mechanisms. For example, carbon steel exhibits an exothermic combustion effect when cut with oxygen assistance, allowing greater maximum thickness for carbon steel than stainless steel at the same power. The table below summarizes the approximate maximum cutting thickness ranges (for acceptable cutting results) of common metal sheets (carbon steel, stainless steel, aluminum alloy) for typical fiber laser cutting machine power levels:

- 1000W (1kW) Class: Carbon steel ~10mm; Stainless steel ~5mm; Aluminum plate ~3mm (^7). Suitable for thin sheet processing, e.g., small sheet metal parts, thin-walled structural components, advertising.

- 3000W (3kW) Class: Carbon steel ~20mm; Stainless steel ~10mm; Aluminum plate ~6mm (^8). Medium power, covering most medium-thin plate applications, efficient for plates below 6~10mm.

- 6000W (6kW) Class: Carbon steel ~25mm; Stainless steel ~18mm; Aluminum plate ~16mm (^9). High-power models, capable of medium-thick plate cutting, e.g., ~20mm steel plates, suitable for general sheet metal fabrication requiring larger processing thicknesses.

- 12000W (12kW) Class: Carbon steel ~40mm; Stainless steel ~35mm; Aluminum plate ~30mm (^10). Ultra-high power, mainly for thick plate cutting needs, used in heavy industry for processing plates over 30mm thick, with cutting efficiency and speed far exceeding low/medium-power equipment.

- 20000W (20kW) Class: Carbon steel up to 60mm; Stainless steel ~50mm; Aluminum plate ~50mm (^11). Top-tier industrial products in the current power range, capable of cutting ultra-thick plates (>50mm) under specific conditions, often used for special large structural parts or scenarios demanding extreme efficiency.

The above data represents the maximum cutting capacity of different power lasers under ideal conditions. Actual applications are influenced by factors such as machine structure, beam quality, assist gas, and cutting speed. It is crucial to emphasize that "maximum cutting thickness" often refers to the limit achievable at lower speeds for piercing, and the cut surface may be relatively rough. To achieve high-quality surface cutting, continuous and stable cutting is typically only possible within about 60% of the maximum thickness. For example, a 500W laser might barely cut 3~4mm stainless steel, but for a smooth cut surface, it’s recommended to stay below 3mm; similarly, the quality cutting thickness for stainless steel on a 3000W machine is around 12mm, beyond which surface finish deteriorates significantly. Therefore, users should focus on the thickness of frequently processed plates, not the machine’s nominal maximum thickness. If daily processing mainly involves thin plates but an oversized power machine is purchased solely for occasional thick plate needs, the return on investment (ROI) period may be significantly prolonged. Conversely, rationally assessing thickness requirements with appropriate margin and selecting a machine with matching power and slight surplus ensures production needs are met while controlling costs.

Analysis of Cutting Thickness Requirements by Industry

Different industries have varying requirements for sheet metal thicknesses, leading to suitable laser power ranges. Below is an analysis of cutting thickness needs and recommended equipment power for typical applications in industries like sheet metal processing, home appliance manufacturing, architectural hardware, sports goods, and advertising signage.

Sheet Metal Processing Industry

"Sheet metal processing" broadly refers to the processing service industry involving cutting and bending various metal plates, serving clients in machinery manufacturing, electrical control cabinets, auto parts, etc. Consequently, the thickness range of processed plates is very wide, potentially from thin stainless steel chassis shells (1~2mm) to thick machine base steel plates (20mm+). Generally, most sheet metal parts are concentrated below 8mm, such as cabinet panels and brackets, making 2kW~3kW laser cutters the mainstay for many sheet metal manufacturers, efficiently handling daily orders. For instance, if the primary daily cutting involves 4~8mm thick plates, a ~3000W machine is recommended to ensure cutting efficiency and provide power margin. For manufacturers frequently processing 12~16mm medium-thick plates, a 6000W-class machine should be considered to guarantee production efficiency and cut section quality. Of course, the sheet metal industry is flexible; some large-scale metal processing centers might need ≥10kW (10,000W-class) equipment to expand ultra-thick plate cutting services. However, the procurement and operating costs of high-power machines are substantial and only economically viable if thick plate business volume is sufficient (exceeding 10% of total workload).

Home Appliance Manufacturing Industry

The home appliance manufacturing sector (including kitchen appliances, washing machines, air conditioners, refrigerators) extensively uses metal sheet parts for casings and structural components, with large volumes of thin sheets. For example, washing machine and refrigerator shells typically use ~1mm galvanized steel or stainless steel plates; air conditioner outdoor unit casings and large electrode rack inner cavity shells are also mostly 1~2mm metal sheets. Traditionally, these thin sheets were mass-produced via uncoiling and stamping. However, for new product trials, small-batch customization, or special models, fiber laser cutting significantly improves development efficiency due to its flexibility and mold-less advantage. Laser cutting in this industry focuses mainly on external sheet metal and thin steel plate components. Typical thicknesses are below 6mm, primarily 1~3mm stainless steel or cold-rolled plates, meaning 1000W~3000W lasers usually suffice. In practice, many appliance factories introduce medium-power (e.g., 2000W) fiber laser cutters for cutting pre-stamping sheet samples, hole punching, and irregular small part cutting. Such equipment can quickly complete tasks like slotting and hole opening for washing machine panels, cutting heat dissipation hole plates for refrigerator back panels, and contour cutting for range hood and stainless steel duct plates. For larger appliance production lines needing to balance efficiency and capacity improvement, cases exist using laser cutters above 3000W to achieve higher cutting speeds on thin plates, speeding up blanking and improving production cycle time.

Architectural Hardware Industry

Architectural hardware typically refers to various metal products used in building decoration and engineering, such as stainless steel railings, decorative screens, metal door/window frames, curtain wall brackets, and pipe supports. Materials in this field are mostly stainless steel and aluminum alloy due to stainless steel’s good corrosion resistance and aesthetics, allowing surface treatments like brushed or mirror finish for decoration. Plate thicknesses in architectural hardware are generally medium-thin: decorative components (e.g., metal screen grilles, stair handrail plates) often use 2~5mm stainless steel; stainless steel security door panels are commonly ~3mm thick; functional brackets may use 6~8mm steel plates based on load-bearing requirements, but thicknesses exceeding 10mm are rare. Since the primary cutting material is stainless steel with moderate thickness, a ~3000W fiber laser cutter is often adequate for most work—a 3kW machine can cut stainless steel up to ~10mm (with quality surface control around 6mm), sufficiently covering common thickness ranges. Simultaneously, medium-power models offer high processing efficiency and quality, producing smooth, burr-free edges on stainless steel decorative parts, significantly reducing subsequent polishing work. For manufacturers needing to cut thicker stainless plates (e.g., 8~12mm curtain wall brackets or structural parts), a 6000W high-power model might be configured to ensure efficiency and penetration capability. Overall, the architectural hardware industry focuses on stainless steel thin plates. Prioritizing cutting quality and efficiency for stainless steel over pursuing maximum thickness is more meaningful during selection.

Sports Goods Industry

Sports goods and fitness equipment manufacturing involves processing various metal parts. For example, bicycle and accessory manufacturing requires laser cutting metal tubes and plates for frames, chainrings, and brake pads. Fitness equipment utilizes cut steel tubes and plates for frame structures and panel casings. Outdoor gear (camping tent poles, hiking poles, etc.) also relies on laser-cut metal materials to meet lightweight and high-precision requirements. Metal plate thicknesses in these applications are mostly medium-thin: bicycle chainrings are typically 2~5mm high-strength steel or aluminum plates; connection plates and seat bracket plates for fitness equipment are mostly 4~8mm thick, rarely exceeding 10mm. Based on this, the sports goods industry commonly uses 1000W~3000W fiber laser cutting machines to meet demand: low-power lasers suffice for cutting thin-walled tubes and thin sheet parts of equipment, maintaining high precision and minimal thermal deformation; for load-bearing plates 6~8mm thick, power above 2000W ensures smooth piercing and good section quality. Notably, some large fitness equipment factories may equip multiple medium-power laser cutters for simultaneous processing or introduce automated loading systems to enhance production efficiency. This industry demands high cutting flexibility due to diverse product models and shapes, making the high-speed switching and programming capabilities of fiber laser cutters important selection factors. Overall, sports goods manufacturing features thin-medium plate, high-efficiency processing. Medium-power laser cutters provide sufficient speed and quality while ensuring the required thickness capability.

Advertising Signage Industry

The advertising signage industry is one of the earliest fields where fiber laser cutting machines were deeply applied. Its processing objects are mainly various metal advertising letters, signs, lightboxes, display racks, and other thin metal products. A significant characteristic of this industry is the high requirement for fineness—most work involves thin plates below 1mm, using materials like stainless steel, aluminum plate, and galvanized steel. Some large outdoor signs may use copper or titanium alloy plates, but thickness is usually small. Due to the need for fine, smooth cuts on letters and signs, fiber laser cutters are almost standard equipment. Based on production capacity and material thickness requirements, the advertising industry generally selects laser cutters in the 500W~3000W power range. Small sign shops commonly use low-power (500W~1000W) models to cut ultra-thin stainless steel lettering; larger sign factories adopt 1500W, 2000W, or even 3000W equipment for efficiency when processing 2~3mm thick stainless steel and aluminum plates. For instance, using a 2000W laser to cut stainless steel illuminated letter casings (~1.0mm thick) is fast and produces a smooth section, enabling direct progression to subsequent bending and welding without secondary polishing, greatly improving sign-making efficiency and quality. Some advertising decoration projects involve stainless steel curtain walls and metal art shapes, typically within 5mm thickness, easily handled by 3000W-class machines. Therefore, for the advertising signage industry, small-to-medium power (<3kW) fiber laser cutters are sufficient and help control procurement and operating costs. Higher-power machines are uneconomical unless used for other thick-plate businesses.

Other Factors to Consider When Selecting Models

Beyond cutting thickness itself, procurement managers should comprehensively consider material types, production efficiency, cost budget, and supplier service when choosing a fiber laser cutting machine:

-

Material Type and Cutting Process: Identify the main materials processed. Laser cutting adaptability varies significantly for different metals. For example, carbon steel readily undergoes combustion with oxygen under laser action, allowing thicker plates to be cut at lower power. However, stainless steel and aluminum alloy require inert gases like nitrogen for melt cutting, demanding higher laser power (at the same power, stainless steel cutting thickness is about half that of carbon steel). Additionally, highly reflective metals like copper and brass are harder to cut. Ensure the selected equipment has suitable anti-reflection laser components and reserves higher power margin than theoretical thickness. In summary, optimize power selection and configuration parameters based on the thickness and characteristics of primary processed materials (steel, aluminum, copper, etc.).

-

Processing Efficiency and Production Cycle Time: Power not only determines whether cutting through is possible but also affects cutting speed and efficiency. In batch production scenarios, higher power can significantly increase speed when cutting the same thickness. For example, a 6kW laser cuts 8mm stainless steel nearly 4 times faster than a 3kW model. On 20mm stainless steel, a 12kW machine is still twice as fast as a 10kW one. If pursuing high output, appropriately selecting power one level higher than the thickness requirement enables high-speed cutting on medium plates, improving per-unit-time output. However, note that the efficiency gain for thin plates has an upper limit with increasing power. Higher power makes the relative constraints of machine idle motion and loading/unloading more apparent. Therefore, balance should be found based on order volume and cycle time requirements.

-

Equipment Cost and Investment Return: Laser power is almost directly proportional to equipment cost. High-power lasers are expensive and consume more electricity. In practical decision-making, evaluate based on Return on Investment (ROI). If most products are thin plates but a 10,000W laser cutter is purchased, it becomes "using a sledgehammer to crack a nut," leaving most machine capability idle and extending the payback period (^15). Reports indicate a 10kW laser cutter may cost ~40% more than a 6kW model, but its per-unit-time output efficiency is only twice that of the 6kW (^25). Thus, enterprises should assess the proportion of high-thickness orders and avoid oversized models: choose a cost-effective model with sufficient but not excessive power under current needs. Consider adding equipment or upgrading later if business expands.

-

After-Sales Service and Maintenance: Fiber laser cutters are high-precision, high-value production equipment. Good after-sales service is crucial for ensuring production continuity. Consider whether the supplier offers timely local technical support, spare parts supply, and training services. Factors like the warranty duration of the laser source, replacement/maintenance cycles for key optical components (cutting head, lenses), and CNC software upgrade support impact long-term operating costs and stability (^6). Choosing reputable brands and manufacturers with comprehensive service systems provides greater assurance for fault response and application guidance. For export-oriented buyers, also consider the supplier’s remote diagnosis capability and spare parts shipping for exported equipment to reduce downtime.

-

Other Factors: Include the machine’s bed size (whether the processing sheet format meets needs), automation level (e.g., pallet changer, automatic loading/unloading devices for high productivity), and safety/environmental configurations (fume extraction, protective covers). For example, factories operating large-scale 24-hour cutting production may prioritize pallet changers for efficient loading/unloading and good dust removal systems. Small custom processing businesses might prioritize footprint, power consumption, and ease of use. In short, compare model functionalities based on your production characteristics to select the most suitable overall performer.

Light CNC Laser Brand Product Recommendations and Application Scenarios

As a professional manufacturer with 15 years of experience in metal cutting equipment, Light CNC Laser offers a comprehensive fiber laser cutting product line covering various power segments, catering to diverse needs from thin sheet/small part processing to thick plate heavy industry manufacturing. Its products are widely used in industries like advertising production, steel structure processing, construction machinery, and sheet metal fabrication, earning a strong reputation for stable quality and complete service. Based on different user group needs, the main models and recommended application scenarios for Light CNC Laser are as follows:

-

Economy Open-Type Laser Cutting Machine (Power 1kW~3kW): Features a standard 3015 format worktable, with optional medium-low power lasers like 1000W, 1500W, 2000W. Capable of high-precision cutting of 1mm~10mm thick carbon steel and stainless steel plates (^7). Positioned for high cost-effectiveness, suitable for start-up small sheet metal workshops, advertising production, kitchen equipment industries, meeting thin sheet processing needs with low investment. For example, the Light CNC Laser classic ST-FC3015 series supports power expansion from 1500W to 6000W, covering metal plate thicknesses from 1mm to 25mm (taking carbon steel as an example), making it ideal for manufacturing various custom metal signs, cabinets/chassis, and hardware parts.

-

Fully Enclosed Pallet Changer Laser Cutting Machine (Power 3kW~12kW): Equipped with an enclosed protective cover and a dual-table automatic exchange system, primarily targeting batch production. Typical configurations include 3000W, 6000W, or higher power fiber lasers, efficiently cutting medium-thick plates (e.g., stainless steel 10~20mm, carbon steel 20~30mm), enabling parallel operation—one table processing while the other loads/unloads. The enclosed structure ensures stable laser and cutting performance, meeting safety and environmental requirements of large factories. This model type is highly suitable for sheet metal processing plants, construction machinery factories, and other users with high demands for capacity and continuous operation. For instance, Light CNC Laser’s fully enclosed pallet changer series is designed for safe and efficient large-batch metal cutting, featuring a metal protective enclosure and automatic exchange platform to improve production cycle time while ensuring operator safety. For enterprises frequently processing large-size plates (e.g., 5×10 feet or larger) and requiring multi-shift continuous production, these medium-high power products are an ideal choice.

-

Heavy-Duty Ultra-High Power Laser Cutting Machine (Power 12kW~20kW and above): Targeting ultra-thick plates and large workpiece cutting needs, Light CNC Laser provides heavy-duty gantry-structure laser cutters configurable with 12000W, 20000W, or even higher power lasers. These models use thickened beds and high-rigidity transmission mechanisms to ensure long-term stability and precision when cutting plates over 40mm thick. Ultra-high power equipment can be used in shipbuilding, bridge steel structures, heavy construction machinery components, and other manufacturing fields. For example, a 20kW model can stably cut 50mm thick stainless steel plates, with carbon steel cutting thickness reaching 60mm under extreme conditions. In terms of processing speed, paired with an advanced CNC system, it achieves efficient cutting of large thick plates, reaching speeds of tens of meters per minute, easily handling batch blanking of large steel plates (^31). It must be emphasized that ultra-high power models are very expensive with high operating costs, suitable only for specific heavy industrial users. Light CNC Laser offers customized solutions in this segment with corresponding process support and training services to help end-users master 10kW+ laser application techniques. For general sheet metal processing enterprises, pursuing this level of equipment is unnecessary—on-demand selection remains key.

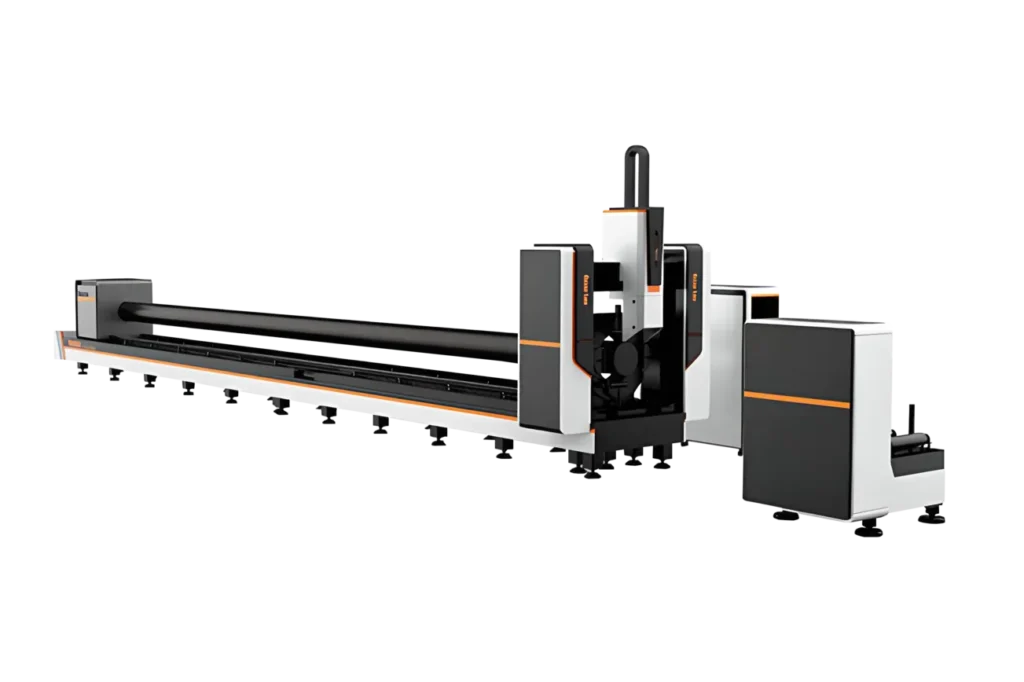

Through the above product series layout, Light CNC Laser basically covers the hierarchical needs from small start-ups to large manufacturing enterprises. Notably, besides flat sheet laser cutters, the brand also has a rich product line in various laser cutting fields (e.g., dedicated tube laser cutters, sheet & tube combo machines (^33)), enabling efficient cutting of square tubes, round tubes, and profiles. This is very convenient for manufacturers needing both sheet and tube processing, allowing one-stop procurement of required equipment and simplifying daily maintenance and training with support from a single vendor.

Summary and Procurement Recommendations

Cutting thickness is the core indicator to consider first when purchasing a fiber laser cutting machine. It is directly determined by laser power and closely related to the type of processed material. Enterprises should select a machine with an appropriate power level based on the material and thickness range of their main products: ensuring efficient cutting of daily production plates while avoiding wasteful oversizing for occasional ultra-thick requirements. When evaluating thickness needs, it’s recommended to follow the "80/20 principle"—select a model capable of high-quality processing for over 80% of order thicknesses. It’s preferable to outsource or use other processes for the remaining 20% of special requirements rather than letting these minority needs dictate the equipment investment direction.

Beyond thickness matching, factors like processing efficiency, equipment investment cost, and subsequent support services should be comprehensively weighed to find the balance between performance and economy. For example, for enterprises primarily processing thin sheets, a medium-power (e.g., 3kW) laser cutter may be more suitable than a high-power one; conversely, factories with substantial thick plate processing volume should invest decisively in sufficiently powerful machines to ensure production efficiency (^15). Simultaneously, prioritize suppliers with strong brand reputation and support capabilities, like Light CNC Laser, which has extensive industry experience, a complete product line, and a robust service system. The brand offers models from 1500W to 20000W and beyond, covering cutting thicknesses from thin sheets to ultra-thick plates (<200mm (^29)). Whether you are a small/medium sheet metal enterprise or a large metal processing group, you can find a solution tailored to your needs.

Finally, procurement decisions should align with the company’s long-term plan and capacity expansion expectations. Laser cutters are high-value, long-term assets whose selection impacts production capability for years to come. Thoroughly researching the cutting effectiveness and efficiency data of different power machines on actual material thicknesses across the market, and rationally comparing performance differences among brands (^35), will facilitate wise choices. We hope this report’s analysis provides practical reference for procurement managers and trading companies—identify key thickness requirements, match the appropriate power level, and consider multiple factors comprehensively to select the laser cutting machine best suited for your business!

References

1, 2. Working Principle and Characteristics of Fiber Laser Cutting Machines

https://www.gx.cnc.com/mobile/news/show-102.html

3, 27. Fiber Laser Cutting Machine – STYLECNC

https://www.stylecnc.cn/fiber-laser-cutting-machine/

4, 5, 7, 8, 9, 10, 11, 32, 35. How Thick Can a Fiber Laser Cutting Machine Cut? – Industry News – Jinan Youmu Machinery Equipment Co., Ltd. – [Official Website]

https://www.acctek.cn/hangyesimwen/460.html

- Practical Guide: How Thick Can Laser Cutters of Different Powers Cut? – Ande Laser Intelligent Equipment (Guangdong) Co., Ltd

https://www.andelaser.com/cn/cut-how-thick-the-board-is/

12, 13, 14, 15, 24, 25. What is the Maximum Cutting Thickness of the Laser Cutting Machine and How to Choose?

https://www.hglaserglobal.com/news/technology-information/Cutting-Thickness-and-Choosing-Guide-of-Laser-Cutters.html - Application of Fiber Laser Cutting Machines in the Home Appliance Industry_Laser Cutting Machine_Sheet Laser Cutting Machine_Jinan Xintian Technology Co., Ltd.

https://www.sdxtkj.com/news/532.html - In Which Industry Fields Are Fiber Laser Cutting Machines Applied? – Zhihu Column

https://zhuanlan.zhihu.com/p/462326284 - Application of Fiber Laser Cutting in the Electrical Appliance Industry – TEVU Chiller

https://www.tevuchiller.com/zh-CN/blog/fiber-laser-cutting-application-in-electrical-appliance-industry_b1055 - Application of Fiber Laser Cutting Machines in the Architectural Hardware Industry_Laser Cutting Machine

https://www.hansmplaser.com/news/detail-569.html

20, 21, 22. Sports Equipment_Rapid Laser Cutting Machine_Fiber Laser Cutting Machine_Laser Cutting Machine_Laser Welding Machine

https://www.quicklaser.com/yundongqicai.html - The Laser Cutting Machine for the Advertising Industry You Want_Haistar Laser Sheet Metal Intelligent Equipment_Sina Blog

https://blog.sina.com.cn/s/blog_bfad91120102ys47.html

26, 28, 29, 30, 33, 34. Chinese Metal Laser and Plasma Cutter Supplier

https://lightcnclaser.com/ - Hans Laser Cutting Machine G3015S 20KW 30KW High Speed Low Cost | Alibaba.com

https://chinese.alibaba.com/product-detail/Hans-Laser-Cutting-Machine-G3015S-20KW-1601195680456.html