Why Fiber Laser Cutting Machines Are Becoming Increasingly Popular?

1. Background of Fiber Laser Cutting Technology and Comparison with Traditional Cutting Methods

Fiber laser cutting technology is a revolutionary metal processing technique that has rapidly emerged in recent years. Traditional metal sheet blanking primarily relies on methods such as punch presses, shearing machines, flame/plasma cutting, each with limitations: shearing machines can only perform straight-line cuts, suitable for simple linear blanking; CNC turret punch presses can punch holes and simple contours but require significant mold investment, exhibiting low efficiency and susceptibility to burrs for complex curves or thick plates, coupled with long mold development cycles and high costs [1]. Flame cutting can handle ultra-thick steel plates but suffers from significant thermal deformation, wide kerf, and slow speed, making it suitable only for rough machining [3]; plasma cutting is relatively fast but has limited precision, with a large heat-affected zone on thin plates and severe cut beveling [4]; high-pressure water jets can cut any material but are slow, have high consumable costs, and create a messy processing environment [5]. In contrast, laser cutting requires no contact with the workpiece, has no tool wear, exhibits strong material adaptability, and can rapidly cut complex shapes with high precision, featuring a narrow kerf, minimal thermal deformation, and a smooth cut surface requiring no secondary processing [6]. The advent of fiber lasers, in particular, has elevated laser cutting to new heights: compared to traditional CO₂ lasers, fiber lasers boast higher photoelectric conversion efficiency, simpler maintenance, no need for laser gases, and a smaller footprint, enabling faster cutting speeds at the same power level [7]. Fiber laser cutting machines can efficiently handle a wide range from micron-thin sheets to plates several tens of millimeters thick, with overall efficiency and automation levels far exceeding traditional equipment like plasma, flame, shearing, and punching machines [8]. These advantages are enabling fiber laser cutting to gradually replace traditional sheet metal processing methods, sparking a technological revolution in the global sheet metal processing industry [9].

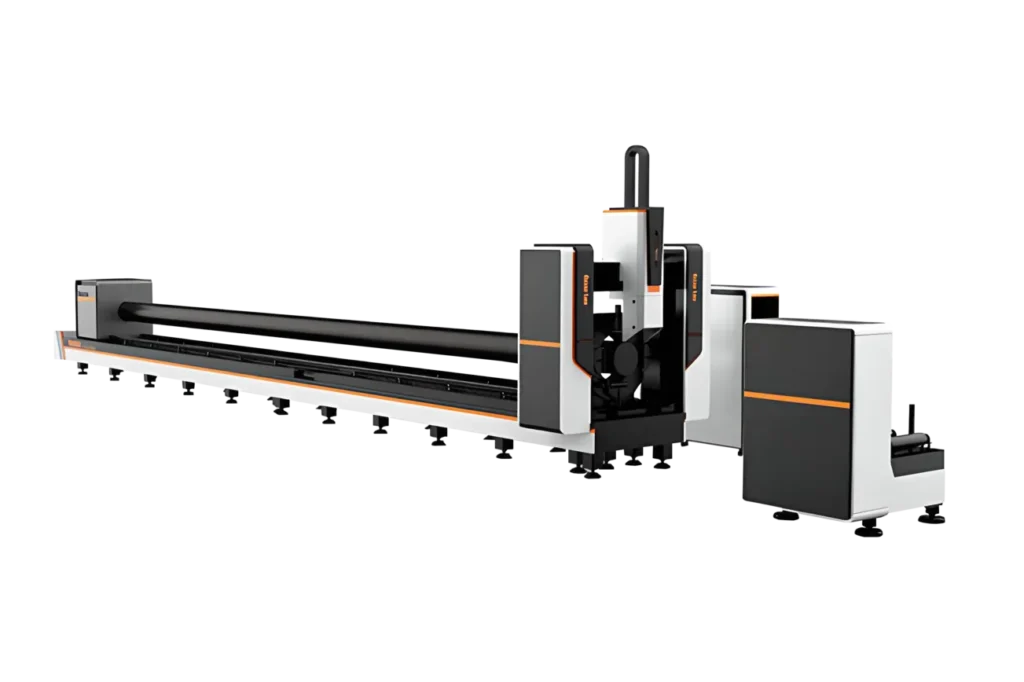

Figure 1: Schematic diagram of a typical fiber laser cutting machine. Modern fiber laser cutting equipment is typically equipped with fully enclosed protective covers and automatic exchange worktables, ensuring safety and environmental protection while increasing production efficiency. The machine integrates a fiber laser source, high-speed motion system, and CNC control unit, enabling high-speed, high-precision cutting of metal sheets.

In summary, fiber laser cutting significantly enhances sheet metal processing productivity and reduces production costs with its high flexibility, precision, speed, and efficiency [10]. It enables cutting without the need for molds, adapting to the flexible manufacturing trend of small-batch, high-variety production, avoiding the disadvantages of high cost and long lead times associated with molds in traditional processes [11]. The laser beam cuts without applying mechanical stress to the workpiece, resulting in no deformation, no burrs, a small heat-affected zone, and high material utilization [12]. Due to these significant advantages, fiber laser cutting machines have rapidly gained popularity across various industries in recent years, becoming the new favorite in the metal processing field.

2. Recent Advancements in Core Technologies of Fiber Laser Cutting

The growing favor for fiber laser cutting machines is inseparable from substantial progress in core technologies in recent years. The continuous increase in laser power is the most visible change. From the common 2-3kW level in the past, 6kW, 8kW, and even "10kW-class" devices above 10kW are becoming increasingly popular, leading to a leap in cutting capabilities [12]. Higher power first brings a breakthrough in the cutting thickness limit. Early fiber lasers, limited by power, could only stably cut carbon steel ≤20mm and stainless steel ≤12mm, forcing reliance on plasma, waterjet, or other processes for thicker plates [13]. Today, 10kW-class fiber lasers can cut stainless steel plates up to 50mm thick and aluminum alloy plates up to 40mm thick [14]; with the launch of 12kW and 15kW fiber lasers, the upper limit of cutting thickness continues to increase, even beginning to satisfy the ultra-thick plate domain previously only processable by flame or plasma [15]. This means laser cutting applications in thick plate processing fields such as shipbuilding, nuclear power, and heavy machinery will gradually expand, making laser replacement of traditional processes possible and further promoting the industry’s healthy development [16].

Higher power also brings a multiplicative increase in cutting efficiency. Power increases significantly accelerate laser cutting speeds. For example, on 3~10mm stainless steel, a 10kW machine cuts over twice as fast as a 6kW machine; on carbon steel, a 10kW laser can achieve high-speed surface cutting at 18~20mm/s for 18-20mm thickness, roughly double the speed of conventional processes [17]. Data shows: cutting 8mm stainless steel, 6kW is nearly 400% faster than 3kW; cutting 20mm stainless steel, 12kW is about 114% faster than 10kW. The substantial improvement in unit output efficiency makes high-power equipment increasingly economical – although the purchase cost of a 10kW-class laser cutter is less than 40% higher than a 6kW model, its output efficiency exceeds twice that, while saving labor and floor space, offering a clear investment advantage [18]. With the maturation and localization of domestic laser technology, equipment prices are becoming more affordable. 10kW-class laser cutters are no longer out of reach and will lead a new round of upgrades in the sheet metal industry [19].

Beyond the laser source itself, the intelligence of the laser cutting head is another key advancement. Modern fiber laser cutting heads are generally equipped with automatic focus adjustment, intelligently regulating the focal position based on material thickness to achieve high-quality cuts from thin to thick plates without manual lens replacement [20]. Additionally, cutting heads integrate sensors and control modules to monitor height, plasma light radiation, etc., during cutting in real-time, enabling intelligent functions like automatic edge finding and focus setting, collision protection, and piercing detection, improving cutting stability and processing quality. Intelligent cutting heads are particularly suitable for high-power lasers. Statistics indicate that China’s demand for intelligent laser cutting heads was about 16,900 units in 2020 and is expected to grow to 73,819 units by 2025, with a compound annual growth rate of 25% [23]. With the widespread application of high-power lasers, intelligent cutting heads are rapidly becoming popular, with prices also dropping from an average of ¥50,000/unit to an expected ¥35,000/unit, making high-power cutting solutions more economical overall [23]. Currently, in the 6kW and above power segment, foreign brands like Germany’s Precitec dominate the market share, but domestic manufacturers are launching 10kW-class local intelligent cutting heads, achieving technological catch-up and import substitution [24]. For example, Shanghai Bichut Electronic Technology launched the BLT series intelligent cutting head, covering power from 6kW to 15kW, and plans to develop products covering even higher power to meet growing market demand [26] [27].

Simultaneously, automation and digital integration are making laser cutting production lines more flexible and efficient. Modern fiber laser cutting machines are often equipped with automatic loading/unloading devices, material tower storage, and finished product sorting systems, achieving unmanned operation from sheet loading and cutting to unloading. This automated flexible production line greatly improves production rhythm, reduces manual intervention and safety risks, and meets the requirements of Industry 4.0 for intelligent manufacturing [28]. Some leading manufacturers have integrated laser cutting units with subsequent bending and welding processes, connecting them via robots and conveying systems to build unmanned sheet metal production cells. Furthermore, in fields like aerospace and automotive manufacturing, fiber laser cutters are combined with robot technology for cutting and processing 3D curved surfaces, enabling automated processing of complex workpieces. In terms of intelligent control systems and software, advanced digital systems can automatically optimize cutting paths (nesting) to improve material utilization; processing monitoring software can track laser power, kerf width, and other parameters in real-time for timely correction and quality assurance. Some new models can also upload equipment operational data to the cloud via IoT for remote monitoring and predictive maintenance, improving equipment uptime. Overall, laser cutting equipment is developing towards "high power, high intelligence, high automation" – high dynamic performance and 10kW-class lasers are becoming standard, with intelligence emerging as the development trend for laser cutting machines [29].

3. Applications and Benefits of Fiber Laser Cutting Machines Across Industries

Leveraging the aforementioned technical advantages, fiber laser cutting machines are playing an increasingly vital role across various industries. From general sheet metal fabrication to specialized manufacturing sectors, almost anywhere involving metal sheet or tube cutting is a significant and suitable stage for laser cutting [30]. Below are examples of typical industries and their benefits:

-

Sheet Metal Processing Industry: Traditional sheet metal processing equipment struggles to meet today’s demands for complex contours and high precision. Fiber laser cutters, with their high flexibility and fast piercing capabilities, are gradually replacing shearing machines, punch presses, etc., becoming standard equipment in sheet metal shops [31]. For small-batch, high-variety custom sheet metal orders, laser cutting eliminates the need for molds, significantly shortening delivery cycles and reducing costs. The application of laser cutting machines has ushered sheet metal manufacturing into an era of automation, flexibility, intelligence, and high efficiency. Industry statistics show that the largest proportion of various sheet metal products currently produced originates from laser cutting processes.

-

Engineering Machinery & Heavy Equipment: Engineering machinery (e.g., excavators, cranes) manufacturing involves processing large quantities of medium-thick plate components. In the past, profiles for these thick steel plates were often cut using flame or plasma, resulting in significant thermal deformation and requiring subsequent milling. The emergence of high-power fiber laser cutting machines has changed this landscape: laser cutting offers high quality, fast speed for complex profiles on medium-thick plates, and with increasing power, can process thicker plates. Laser cutting provides high quality, with vertical, smooth cuts free of dross, allowing parts to proceed directly to welding assembly without rework, reducing grinding and fitting time. As laser cutting gradually replaces traditional flame/plasma for thick plates, it not only improves precision and efficiency but also reduces noise and dust pollution during processing, aligning with green manufacturing trends. Currently, some heavy industry enterprises have introduced 10kW-class laser cutters for cutting high-strength alloy steel plates, enabling precise blanking of key structures and improving product quality stability.

-

Automotive Manufacturing: Laser cutting technology is widely used in the automotive industry, covering parts manufacturing, prototype development, and other stages. Many high-strength steel parts on car bodies and chassis (e.g., door reinforcement plates, B-pillar reinforcements) require high-precision blanking to ensure assembly dimensions and vehicle safety. Traditional machining struggles to achieve the required precision and is inefficient, while fiber laser cutting, with its contactless processing, burr-free edges, and good consistency, can rapidly batch-cut complex contours to meet the strict tolerance requirements of automotive parts. For example, common components like brake pads and instrument panel frames can be cut to shape in one step with a laser, avoiding micro-cracks and residual stress caused by stamping, enhancing part reliability. Additionally, in car body manufacturing, robots equipped with fiber laser cutting heads can precisely trim and blank 3D body parts (e.g., roof openings, door/window frames), replacing traditional die punching, thus enabling flexible body production. Many automakers also use laser cutting for small-batch sheet part processing during new model prototyping, saving mold development time and accelerating R&D progress. In short, the advantages of high efficiency, burr-free edges, and one-step forming make laser cutters powerful tools for enhancing quality and efficiency in automotive manufacturing.

-

Hardware Kitchenware & Sanitary Ware Industry: Kitchen and sanitary ware products (e.g., stainless steel sinks, range hood casings, metal bathroom cabinets) are largely made from thin metal sheets. Traditional processing methods faced issues of low efficiency, high mold wear, and high costs. After introducing fiber laser cutting, manufacturers can quickly and accurately cut stainless steel sheets, obtaining smooth and neat edges, eliminating the need for grinding and polishing. The high speed and precision of laser cutting significantly improve the processing efficiency of kitchen and sanitary hardware. Simultaneously, laser processes easily enable product customization and complex pattern processing, meeting the diverse design needs of high-end kitchen and sanitary products. This effectively solves the past dilemma for kitchenware manufacturers of balancing efficiency and customization, earning strong industry recognition. For instance, some stainless steel sheet factories using laser cutting for blanking report production cycles shortened by over 50% compared to traditional mold stamping, with stable cut quality and significantly reduced rejection rates.

-

Fitness Equipment Industry: Fitness equipment like treadmills, exercise bikes, and strength training machines contain numerous metal parts, including various specifications of tubes and sheets. Traditional processing required repeated process adjustments for different tube diameters and sheet thicknesses, resulting in low efficiency and difficulty ensuring precision. Fiber laser cutting offers high flexibility, easily cutting tubes and sheets of different shapes, and enabling complex contours, holes, and slots based on equipment design. For example, on the steel tube frame of strength equipment, lasers can precisely cut connection holes and support slots, ensuring assembly accuracy. The clean, burr-free laser-cut surfaces require no rework, resulting in excellent appearance and feel after assembly. Compared to traditional sawing and drilling, lasers greatly improve processing quality and efficiency, reduce process switching, and achieve multi-functionality with one machine. Some large fitness equipment manufacturers use combined sheet-and-tube laser cutting machines, concentrating sheet and tube cutting on automated lines, increasing capacity while lowering labor costs.

-

Advertising Signage Industry: The production of metal letters, signs, and decorative patterns is ideally suited for laser cutting. In the past, advertising letters were often made using mechanical punching/shearing or plasma cutting, resulting in poor precision and burrs on cut edges, requiring significant rework grinding. After introducing fiber lasers, materials like thin stainless steel and galvanized sheets can be cut at high speed into various fonts and complex graphics with smooth edges, eliminating secondary grinding. The high positioning accuracy of laser cutting ensures dimensional consistency for mass-produced standardized illuminated letters. For custom-shaped signs, importing the design pattern allows the laser to "cut once and complete," drastically shortening delivery cycles. High-precision laser cutting reduces rework probability, improves work efficiency, and saves costs for enterprises. Currently, the metal parts of products like city neon signs and stainless steel 3D letters are mostly laser-cut, achieving aesthetic and durable results.

-

Household Appliance Manufacturing: Over 30% of components in household appliances (air conditioners, refrigerators, washing machines, microwave ovens, etc.) are metal sheet parts, mainly used for casings and frame structures. Traditional blanking relies on punch presses and shearing, but faces issues like low efficiency, high mold investment, and average processing precision. The application of fiber laser cutting in the home appliance industry effectively addresses these pain points: laser cutting shapes various sheet metal appearance parts and mounting plates without molds, improving processing quality and saving costs in machining steps; simultaneously, laser cutting, being flexibly programmable, can

quickly adjust drawings with product updates, greatly shortening the blanking cycle. After introducing laser cutting technology, many appliance factories have seen significant improvements in part consistency, ensuring better assembly precision and appearance quality. For example, the sheet metal casing of an air conditioner outdoor unit, which previously required multiple sets of progressive dies for step-by-step processing, can now be cut and pierced in one step with a laser, not only reducing processes but also lowering noise and safety risks. Under the trend of increasing refinement and complex shapes in appliance sheet metal parts, fiber laser cutting fully meets the demand for high-precision, diversified processing and has become an indispensable tool in appliance manufacturing.

-

Electrical Cabinets & Sheet Metal Enclosures: Various cabinets and enclosures we commonly see, such as distribution cabinets, communication cabinets, and filing cabinets, are mostly formed by bending and welding thin steel sheets, demanding high processing efficiency for sheet metal parts. Traditionally, standardized batch products might use punch press molds for holes and slots, but mold changes were inconvenient during product updates or output variations. Fiber laser cutting machines provide a flexible and efficient solution: utilizing multi-station automatic loading/unloading laser cutting systems, multiple cabinet flat patterns can be nested and cut simultaneously on one machine; for some thin sheets, even "double-layer stacking cutting" is possible, greatly boosting output efficiency. For instance, for a typical 1.2mm thick cabinet door panel, the laser can cut the door outline and dense holes in one step, saving nearly half the time compared to step-by-step punch press processing. For diverse, small-batch custom enclosures, lasers offer unparalleled flexibility, enabling blanking based on drawings without new molds, helping electrical equipment manufacturers reduce inventory and the cost of responding to custom orders. It is foreseeable that the widespread application of fiber laser cutting in the cabinet and enclosure industry is an inevitable trend.

-

Medical Device Manufacturing: Medical devices, especially surgical instruments and tools, often use materials like stainless steel and titanium alloys, requiring high processing precision and surface finish. Traditional machining methods struggled with the difficulty and inefficiency of processing delicate medical instruments. Fiber laser precision cutting has significant potential in this field. For example, stainless steel surgical blades and various precision tools for minimally invasive surgery can achieve smooth, sharp edges through laser micro-cutting, avoiding micro-crack contamination caused by mechanical machining; mesh structures and complex contours of orthopedic implants can also be achieved through one-step laser forming cutting. The medical device industry typically involves diverse specifications and small batches. Using laser cutting ensures high precision and consistency while facilitating flexible production adjustments based on design changes, making it widely adopted by medical device manufacturers. Furthermore, in fields like aesthetic medical devices, laser cutting is also used to manufacture internal precision metal structural parts and casings, ensuring material purity and dimensional accuracy through non-contact processing. Overall, fiber laser cutting provides an advanced means for the precision manufacturing of medical devices, enhancing product quality levels.

In summary, the application of fiber laser cutting machines covers almost all industries requiring the cutting and forming of metal sheet and tube materials. By adopting laser cutting technology, various industries have achieved cost reduction, efficiency improvement, and process upgrading: reducing mold investment, shortening production cycles, improving product quality, and enhancing design flexibility. Against the backdrop of manufacturing’s shift towards intelligence and flexibility, laser cutting machines are playing an increasingly critical role. Their rising popularity is an inevitable outcome of industry development.

4. Material Suitability for Different Power Levels and Equipment Selection Recommendations

Fiber laser cutting machines can be subdivided into several tiers based on laser power. Different power levels are suitable for different processing thickness ranges and application scenarios. When selecting equipment, it’s essential to choose the appropriate power level considering factors like material type, thickness range, and production capacity requirements to meet both technical demands and economic efficiency. Below are the cutting capabilities and application suggestions for typical power levels:

| Laser Power (CW) | Max. Cutting Thickness – Carbon Steel | Max. Cutting Thickness – Stainless Steel | Max. Cutting Thickness – Aluminum Alloy | Typical Application Scenarios |

|---|---|---|---|---|

| 1.5 kW Class | ≈14 mm Carbon Steel (Best effect below 6 mm) |

≈6 mm Stainless Steel (N₂ assist) |

≈4-5 mm Aluminum Alloy | Thin sheet processing, small sheet metal part manufacturing, advertising letters, craft cutting, etc. Suitable for jobs primarily involving thin sheets. Low equipment investment and operating costs. |

| 3 kW Class | ≈20 mm Carbon Steel (Can cut ~20mm, best quality in 8-12mm range) |

≈10 mm Stainless Steel (Can cut ~10mm, easy to obtain clean section within 6mm) |

≈8 mm Aluminum Alloy (Burr-free high-speed cutting for thin sheets, slower speed required for thick Al) |

Medium-thin plate batch processing, general-purpose model for sheet metal contract manufacturers. Balances high-speed thin sheet processing with medium-thick plate cutting needs. Good balance between capacity and investment. |

| 6 kW Class | ≈25-30 mm Carbon Steel (Can cut 25mm+, slow O₂ cutting for thick plates) |

≈15 mm Stainless Steel (High-speed N₂ cutting up to 10mm+; bright surface cutting possible for thick plates) |

≈10-12 mm Aluminum Alloy | Main model for medium-thick plate processing, suitable for engineering machinery, heavy industrial part cutting, etc. Significantly faster than 3kW models (e.g., 4x faster for 8mm SS [17]), stronger thick plate capability, wide applicability. |

| 12 kW Class | ≈40-50 mm Carbon Steel (Can cut 50mm+ mild steel, suitable for thick plate blanking) |

≥30 mm Stainless Steel (Can cut SS thick plates to 30mm+, N₂ can cut medium-thick plates for oxide-free cuts) |

≥20 mm Aluminum Alloy (High-reflectivity materials require coating or beam adjustment, still capable of thick Al cutting) |

Ultra-thick plate processing, high-end manufacturing fields (e.g., shipbuilding, bridges, petrochemical vessels). Suitable for enterprises frequently needing to cut plates above 20mm. Can effectively replace some plasma/flame processes, significantly reducing thick plate processing deformation and subsequent grinding costs. |

| 20 kW Class | ≥50 mm Carbon Steel (Can penetrate 50mm+ steel, max thickness depends on material & beam quality) |

≥50 mm Stainless Steel (Can cut ultra-thick SS, but speed advantage diminishes with increasing thickness) |

~30-40 mm Aluminum Alloy (High power can cut thick Al but requires anti-reflection measures) |

Ultra-high power pre-engineering model, used for extremely thick laser cutting and high-speed production scenarios. E.g., large steel structure blanking, military special material processing. Can partially replace traditional plasma/flame cutting. Consider when higher capacity or special thickness processing is required. |

(Note: Thickness values in the table are typical achievable values. Actual cutting capabilities vary with material composition, required cut quality, assist gas, and operating conditions. [44] indicates laser power determines maximum penetration thickness, e.g., 20 kW can penetrate 50 mm CS while 5 kW only 15 mm, but the effect of power increase on max thickness diminishes beyond a critical point.)

From a selection perspective, if a company’s main business focuses on thin sheets (e.g., stainless steel ≤3 mm, carbon steel ≤6 mm), then low-to-medium power fiber laser cutting machines in the 1~2 kW range are sufficient and offer low cost and energy consumption advantages. For general sheet metal processing involving a medium thickness range (e.g., large volumes of 5~10 mm stainless steel and 10~20 mm carbon steel), 3~6 kW class equipment is a more economical and practical choice; machines in this power range are moderately priced yet cover the vast majority of common plate thicknesses, offering high speed and precision for thin sheets, significantly boosting productivity compared to lower-power models. If the business involves significant thick plate (20 mm+) processing with high demands on cut quality, such as in engineering machinery or heavy manufacturing, then high-power 10kW-class equipment (e.g., 12 kW+) should be considered. High power not only expands thick plate processing capability but, more importantly, enables burr-free, high-quality cutting at much higher speeds for the same thickness [45] – for example, using nitrogen for high-speed cutting of carbon steel up to 12 mm thick, efficiency is 6~7 times that of traditional oxygen cutting [46]. Therefore, for large sheet metal processing centers with heavy workloads pursuing output efficiency, investing in a 10kW-class laser cutter can often achieve rapid return on investment through increased production [48].

Of course, higher power means higher equipment prices and operating costs. Selection should depend on actual production capacity needs and ROI. Practical experience shows that when cutting thickness is near the upper limit of a machine’s capability, further power increases yield diminishing returns on efficiency improvement. Therefore, blindly pursuing "higher power is better" is not advisable; instead, select a power level that is "sufficient with a slight margin" based on current technological levels. Simultaneously, supporting factors like factory power supply, fume extraction, dust removal, and floor space must be considered to meet the requirements of high-power lasers (e.g., a 20 kW laser consumes massive power, generates significant heat, and produces finer dust particles, necessitating powerful ventilation and dust extraction systems). In summary, small startups should begin with low-power models and gradually add high-power machines as business grows, achieving a mix of equipment power levels. This avoids excessive initial investment while enhancing overall efficiency through high-end equipment for thick plates and low-power machines for thin sheets. When purchasing, prioritize mature mainstream brands and equipment with localized service support, considering manufacturer reputation, after-sales guarantees, and application cases from similar users to ensure the selected laser cutter can deliver stable benefits.

5. Future Trends in Fiber Laser Cutting Technology

Looking ahead, fiber laser cutting machines will continue to develop towards higher power, greater intelligence, and stronger integrated functions, constantly expanding application boundaries and enhancing manufacturing efficiency. Key trends include:

-

Ultra-High Power Laser Cutting: With advancements in laser technology, ultra-high-power (>20 kW) fiber lasers are entering practical application. For instance, Germany’s Precitec’s new ProCutter 2.0 laser cutting head can handle laser power up to 85 kW [47], providing hardware support for future ultra-high-power processing. Leading domestic and international manufacturers have successively launched 30 kW, 40 kW, and even higher-power laser cutting equipment, breaking past limitations of laser cutting in specific fields. Reports indicate that China has developed an 80 kW-class laser cutter prototype, achieving 30~50% higher speed than 60 kW models when air-cutting 20~60 mm carbon steel plates, with significant efficiency gains also on thick stainless steel [48]. It is foreseeable that the leap from the "10kW-class" to the "100kW-class" will be the direction of competition in high-end laser cutting technology in the coming years. Ultra-high-power lasers will further increase cutting speeds and are expected to cut ultra-thick steel plates (e.g., 100 mm+) that were previously uneconomical to process with lasers. This will open markets such as large shipbuilding, marine engineering, and ultra-thick pressure vessels, challenging traditional flame/plasma cutting. Of course, ultra-high power also comes with higher technical difficulty and cost, and widespread application will only occur when scaled demand in specific fields reaches a certain level [49]. In the next 3-5 years, high-power laser prices are expected to continue falling, and the market share of high-power equipment will further increase. Industry forecasts predict significant growth in demand for high-power and ultra-high-power laser cutting in communications, electrical appliances, machinery, and new energy vehicles by 2025 [50].

-

Multi-Function Combined Processing Equipment: To meet diverse processing demands, laser cutting is deeply integrating with other processes, giving rise to multi-functional combined processing equipment. One typical trend is the "Laser + Punch" combination machine, integrating a CNC turret punch press and a fiber laser cutter into one unit. Companies like TRUMPF, Prima Power, Yawei, etc., offer mature laser-punch combination machines [51]. Such equipment uses the punch press for high-speed hole punching, flanging, forming, tapping, etc., and the laser for complex outer contours, achieving complementary advantages. One machine can complete all processing steps from sheet to part, eliminating multi-machine transfers and significantly improving flexibility and efficiency [52]. Practical data shows that laser-punch combination machines can improve efficiency by over 60% compared to separate "punch + laser" processing, increase material utilization by over 15%, and significantly reduce overall processing costs [53]. More importantly, since the punch press can automatically separate parts from the sheet skeleton and sort/unload them, truly unmanned automatic production is achieved – solving the problem of manual part removal after automatic loading/unloading in pure laser cutters [54]. Besides punch combination, another trend is the combined sheet-and-tube laser cutting machine, i.e., one device capable of cutting both metal sheets and tubes/profiles [55]. These models combine a flat sheet cutting worktable with a tube clamping and rotating mechanism, greatly improving equipment utilization and process scope for manufacturers, especially suitable for SMEs needing to process diverse workpieces. Some manufacturers have also launched coil laser cutting production lines, directly uncoiling and leveling metal coils before feeding them into the laser cutter for continuous part cutting (commonly known as "laser blanking lines"), replacing traditional stamping blanking lines to meet flexible blanking demands in industries like automotive. It is foreseeable that future laser cutting equipment will develop towards "multi-functionality per machine": besides cutting, they may integrate modules for engraving, marking, drilling, and even additive manufacturing functions, providing one-stop processing solutions. This trend towards combination can further compress production steps, enhancing production flexibility and space utilization.

-

Automated Flexible Production Lines and Smart Factories: The rapid development of laser cutting is also driving changes in metal processing models. In the future, more laser cutting cells integrated into automated production lines and smart factories will emerge. In terms of equipment automation, besides continuous upgrades to conventional auto-loading/unloading systems (faster vacuum suction cup loading, multi-pallet cyclic exchange, etc.), technologies like vision recognition, robotic sorting, and Automated Guided Vehicles (AGVs) will be integrated into open laser processing workshops, achieving fully automated linkage from raw material to finished product [56]. For instance, vision systems can recognize the orientation of parts on sheet remnants, enabling robots to precisely pick up and sort/unload parts after cutting, drastically reducing manual intervention. At the factory management level, with the advancement of smart manufacturing and Industry 4.0, laser cutting cells will connect to factory MES/ERP systems, achieving linkage with order management and inventory management. Future open-architecture laser cutting equipment will integrate more remote monitoring, diagnosis, and optimization functions [57] – managers can monitor the output and status of each machine in real-time, using big data analytics for predictive maintenance to avoid unplanned downtime. Simultaneously, AI optimization of cutting parameters and automatic path planning will mature, enabling equipment to adapt to different materials and thicknesses, reducing reliance on operator experience. It is foreseeable that within a few years, highly automated, flexible "unmanned laser cutting workshops" will emerge in metal manufacturing clusters: a few technicians monitor the entire system controlling laser cutters and robots, with the entire production process automatically executed based on digital instructions, leading to a significant leap in labor efficiency and production capacity.

In summary, driven by continuous technological innovation, fiber laser cutting machines will maintain strong development momentum for the foreseeable future. Higher power, more intelligent cutting heads, and highly automated production models will continuously expand the application scope and economic benefits of laser cutting. The next 30-40 years can be anticipated as a golden period for laser processing technology development. As a vital part of advanced manufacturing, the prevalence and influence of fiber laser cutting will continue to expand.

For the manufacturing industry, seizing this technological trend for process upgrades and equipment selection will help improve production efficiency, product quality, and enhance market competitiveness. Behind the increasing popularity of fiber laser cutting machines lies the epitome of manufacturing technology evolving towards efficiency, flexibility, and intelligence. Industries adapting to this trend and accelerating the adoption of intelligent equipment like laser cutting will undoubtedly inject strong momentum for achieving high-quality development.

References

- Wuhan Sango Optoelectronic Equipment, "Application Analysis of Fiber Laser Cutting Machines in the Sheet Metal Industry", Laser Manufacturing Network, 2015. p. 57

- rongpuiwing, "Brief Discussion on the Application of Laser Cutting in the Sheet Metal Industry", Sheet Metal & Fabrication, 2019. p. 11

- SC Shenchong, Product Introduction: Fiber Laser Cutting Machine, 2024. p. 8

- International Metal Processing Network, "High-Power Lasers: The Era of 10kW-Class Laser Cutting Machines Has Arrived", 2021. pp. 15, 17

- Huaon Industrial Research Institute, "Analysis of the Competitive Landscape of China’s Laser Cutting Head Industry in 2020", 2022. pp. 22, 24

- Xintian Laser, "Application Industry Fields of Laser Cutting Machines", Xintian Laser Official Website News, 2023. pp. 30, 35

- Xintian Laser, Ibid. pp. 38, 58

- Jinan Youmu Machinery, "How Thick Can a Fiber Laser Cutting Machine Cut?", Industry News, 2021. p. 43

- Precitec GmbH, "ProCutter 2.0" Cutting Head Product Page, 2023. p. 47

- Ritter Machine Tool, "CNC Turret Punch Press + Fiber Laser Cutting Combination Machine", New Product Promotion, 2024. pp. 52, 53

- Penta Laser, "Laser Empowerment: The Path of Innovation in the Shipbuilding Industry", 2023. p. 33

-

Sohu Finance, "Trend Analysis of China’s Laser Cutting Industry…by 2025", 2023. pp. 49, 55

1 2 3 4 5 56 57 Application Analysis of Fiber Laser Cutting Machines in the Sheet Metal Industry

https://www.laserfair.com/yingyong/201507/23/61430.html

6 9 10 11 Brief Discussion on Laser Cutting in the Sheet Metal Industry_Cutting_Process Consultation_Laser Manufacturing Network

https://www.laserfair.com/mobile/jiguangyingyong/201906/26/397.html

7 8 Laser Cutting Machine-SC Machinery

https://www.shen-chong.com/zh/%E6%BF%80%E5%85%89%E5%88%87%E5%89%B2%E6%9C%BA/

12 13 14 15 16 17 18 19 45 46 High-Power Lasers: The Era of 10kW-Class Laser Cutting Machines Has Arrived-International Metal Processing Network

https://www.mmsonline.com.cn/info/314395.shtml

20 21 Laser Processing Shows Significant Development Trend Towards 10kW Laser Power and Intelligence-News Aggregation Channel

https://www.laserfocusworld.com.cn/DelN.asp?id=9513

22 23 24 25 26 27 Analysis of the Competitive Landscape of China’s Laser Cutting Head Industry in 2020, "Chart" | Foreign Brands Dominate High-End Market – Huaon Intelligence Network_Huaon Industrial Research Institute

https://www.huaon.com/channel/trend/784124.html

28 52 53 54 New Product Promotion: CNC Turret Punch + Laser Cutting Combination Machine-CNC Press Brake_Shearing Machine_Laser Cutting Machine-Ritter Machine Tool (Suzhou) Co., Ltd.

https://www.deratech.cn/c42385/195.html

29 [PDF] Information: 2024 Machine Tool Industry Independent Innovation and Product Quality Research Work Launches DMCs Sen…

https://www.cmtba.org.cn/upload/ewebeditor/attach/20240830162954.pdf

30 31 32 34 35 36 37 38 42 58 Laser Cutting Machine Application Industry Fields_Laser Cutting Machine_Sheet Laser Cutting Machine_Jinan Xintian Technology Co., Ltd.

https://www.sdxtkj.com/news_details/1180111459310895104.html

33 Laser Empowerment: The Path of Innovation in the Shipbuilding Industry – Penta Laser (Zhejiang) Co., Ltd.

https://www.pentalaser.com.cn/news_detail/5.html

39 Advantages of Laser Cutting Machines in the Appliance Industry – Jinan Lingxiu Laser Equipment Co., Ltd. is a…

http://lingxiulaser.com/m_shownews.asp?id=903

40 Application of Laser Cutting Machines in Appliance Industry Processing Technology, Unparalleled Advantages_Laser Cutting Machine_Fiber…

http://xqilaser.com/newsshow-338-3.html

41 Fiber Laser Cutting Machine Solutions for Electrical Manufacturing_Industry News_Guangtiandi CNC – Aluminum Plate Engraving Machine

http://www.gtdcnc.com/show-19-345.html

43 1500W Fiber Laser Cutting Machine for Metal Door Process Manufacturers|GoldenLaser

https://www.goldenfiberlaser.com/zh/1500w-fiber-laser-cutting-machine-for-metal-door.html

44 How Does the Power of a Fiber Laser Affect Laser Cutting Quality?

https://www.jsrayclean.com/news/html/71909.html

47 ProCutter 2.0 – Laser Cutting up to 85 kW

https://www.precttec.cn/laser-cutting/products/laser-cutting-head/pro-cutter/

48 [PDF] Policy Encourages R&D Investment in Industrial Mother Machine Enterprises, Focus on Cyclical and Robot Industry Chains

https://pdf.dfcfw.com/pdf/H3_AP202309251599762538_1.pdf

49 Analysis of China’s Laser Cutting Industry Policies, Market Size, and Trends by 2025 – Sohu

https://www.sohu.com/a/914437321_120928700

50 Punching Laser Machines | TRUMPF

https://www.trumpf.com/zh_INT/products/machines-systems/punch-laser-machines/

51 Punch-Laser Combination Machine MF3048HL / MF30510HL – Murata Machinery

https://www.muratec.com.cn/sm/products/lp/

55 Crucial! 9 Major Desktop Machining Equipment Design Trends for 2025

https://www.nycd-design.com/cn/source/2025-desktop-machining-equipment-design-trends.html

2 Responses

magnificent post, very informative. I ponder why the

othher experts of this sector don’t understand this. You

must proceed your writing. I’m sure, you have a huge readers’ base already!

I simply could not depart your web site before suggesting that I extremely enjoyed the standard info an individual provide for your visitors? Is going to be again incessantly to check up on new posts