Versatile Plasma Cutting Machines for All Metal Cutting Needs

What is Plasma Cutting Machine?

Plasma cutting machine is the equipment that use high-temperature plasma arc to locally melt the metal at the workpiece kerf, and blow the molten metal away by the momentum of the high-speed plasma to form a cut. Specifically, the plasma cutting machine forms a high-temperature, high-speed plasma arc through compressed air or other working gases, transfers the arc power to the workpiece, and the high heat causes the metal to melt, while the high-speed airflow blows the melted metal away to form a narrow cutting slit. Plasma cutting machine has the advantages of fast cutting speed, high cutting precision and wide range of adaptability. It can cut a variety of metals, including stainless steel, aluminum, copper and other materials that are difficult to cut by traditional methods. Since the temperature of the plasma arc is extremely high, which can reach 18,000℃-23,000℃, almost all electrically conductive metals can be cut with plasma. In addition, plasma cutters can cut very fast, especially when cutting thin plates, at speeds up to 3-15 times that of oxygen cutting. Plasma cutting has narrow slits, flat cuts, and low workpiece distortion, making it ideal for industrial applications that require high precision and efficiency.

What Styles of Plasma Cutter We Can Offer?

We can provide all kinds of plasma cutting machines, no matter you are cutting thin or thick plates, square pipes, round pipes, H-beams, channels, I-beams, profiled steel, etc., no matter you are just starting your metal cutting business, or you are already a professional processor, and no matter you are a self-employed person, a distributor or an agent, we can provide you with the most suitable equipment according to your needs. From entry-level models to the most professional industrial plasma cutter, from the regular small, medium-sized tabletop 4*8 feet, 5*10 feet, 6*20 feet to the larger sizes of large format gantry plasma cutters, 5-axis or 8-axis plasma pipe cutters, plasma and flame integrated machines, plasma laser cutter, or cnc plasma tube cutter, and simple pipe cutters, etc., and From the cost-effective LGK plasma power supply made in China to the high-end Hyperthern plasma power supply imported from the USA, we provide them all.

Explore Our Range of Plasma Cutting Machines for Sheet and Tube Processing

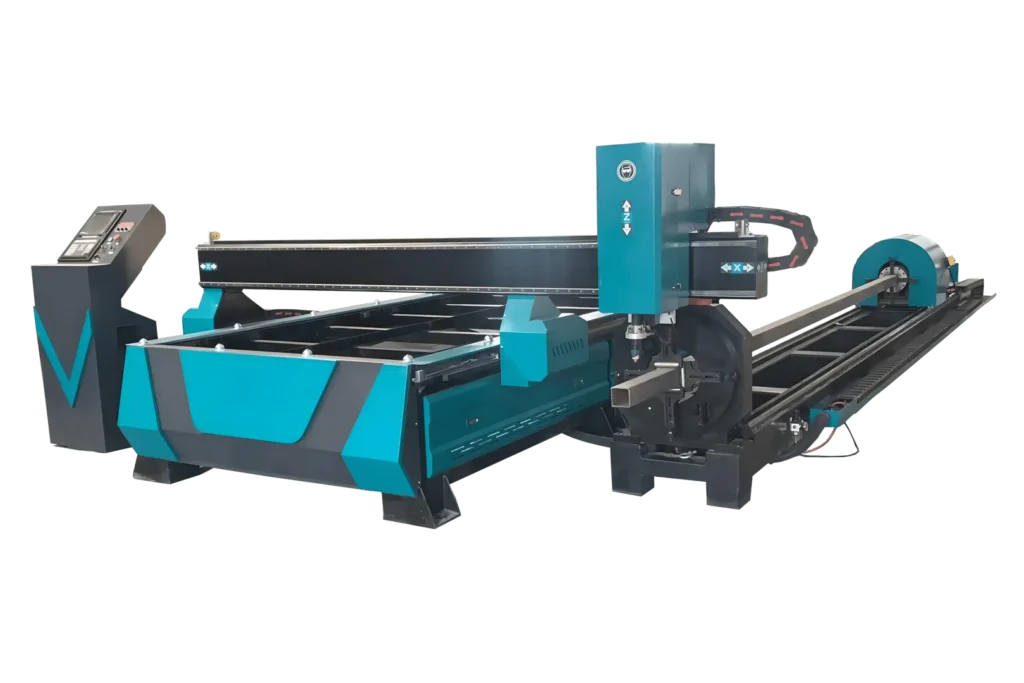

Plasma Cutting Machine

Plasma cutting machines are robust machine for heavy-duty metal cutting, known for their powerful performance and reliability. Ideal for indoor and outdoor factories, thick plates, and reflective materials, these plasma machine CNC systems excel in challenging conditions.

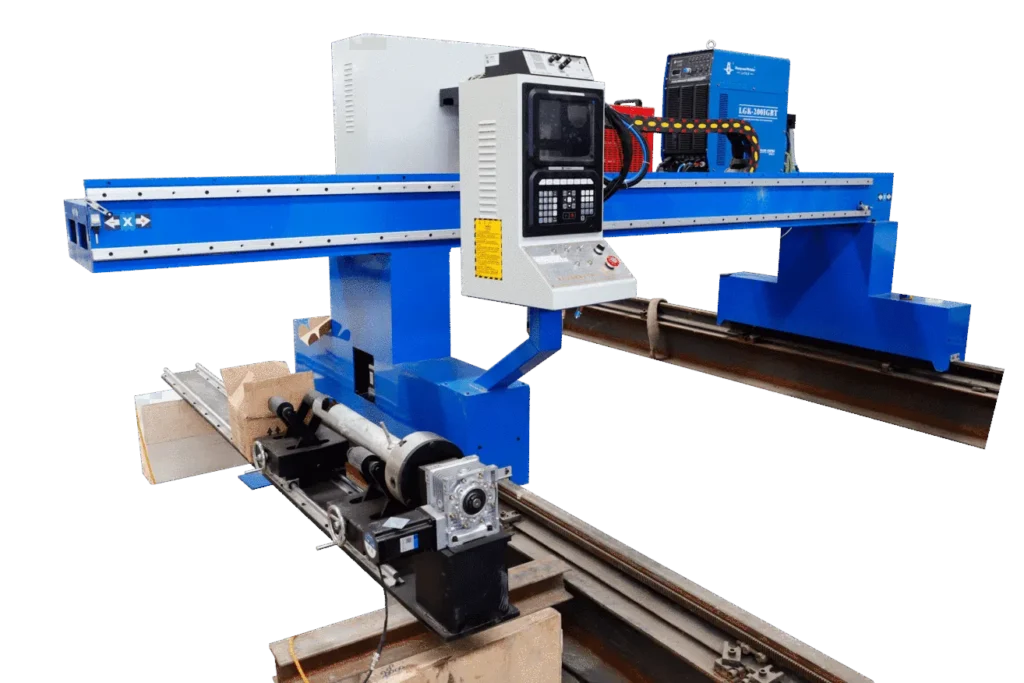

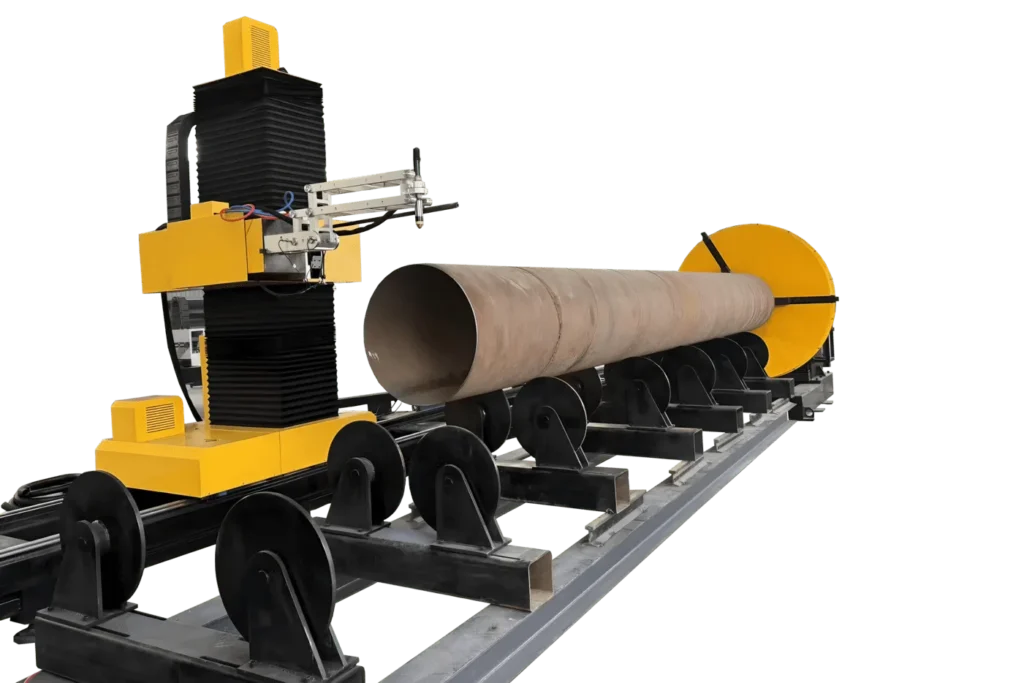

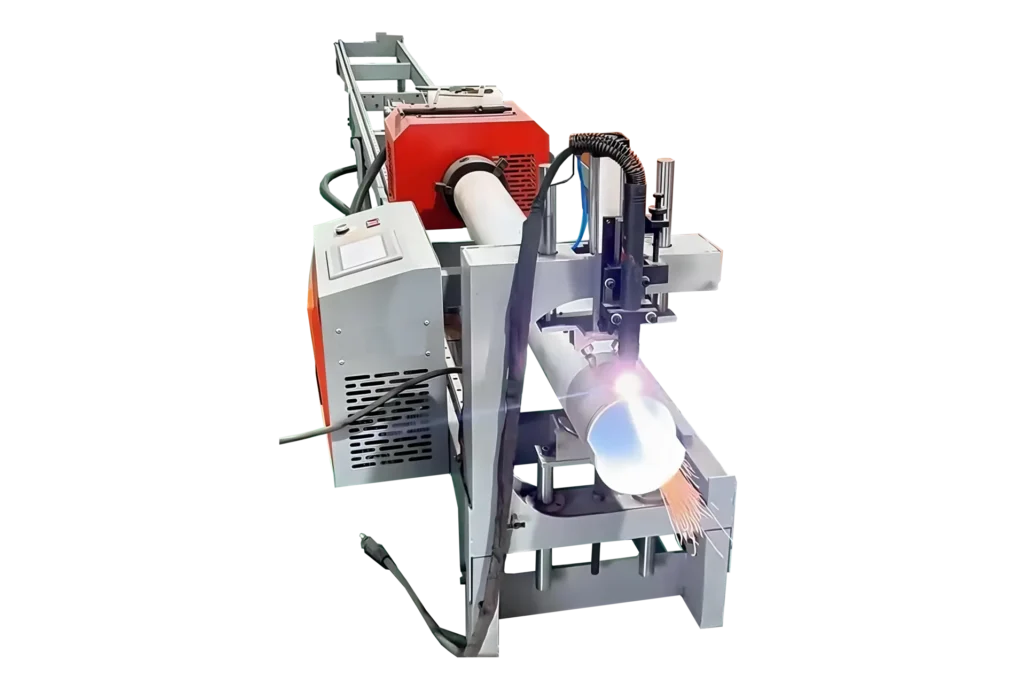

Plasma Tube Cutter

CNC Tube Cutting Machines are specialized equipment in the fiber laser cutter and plasma cutter categories, designed for tube and pipe processing. Available in various models, they handle round, square, H-shaped, and custom-shaped tubes with high precision. Depending on material size and efficiency needs, you’ll find a range of options to suit your requirements. Explore competitive tube laser cutting machine prices and advanced fiber laser tube cutting machines to CNC plasma tube cutters tailored to your projects.

Affordable CNC Plasma Pipe Cutting Machine | Simple Tube Cutter for Round Pipes

Affordable CNC plasma pipe cutting machine, designed for easy cutting of round pipes with diameters from 50-219mm. Simple operation with electric chuck for auto clamping, ideal for various materials and low-cost, efficient cutting.

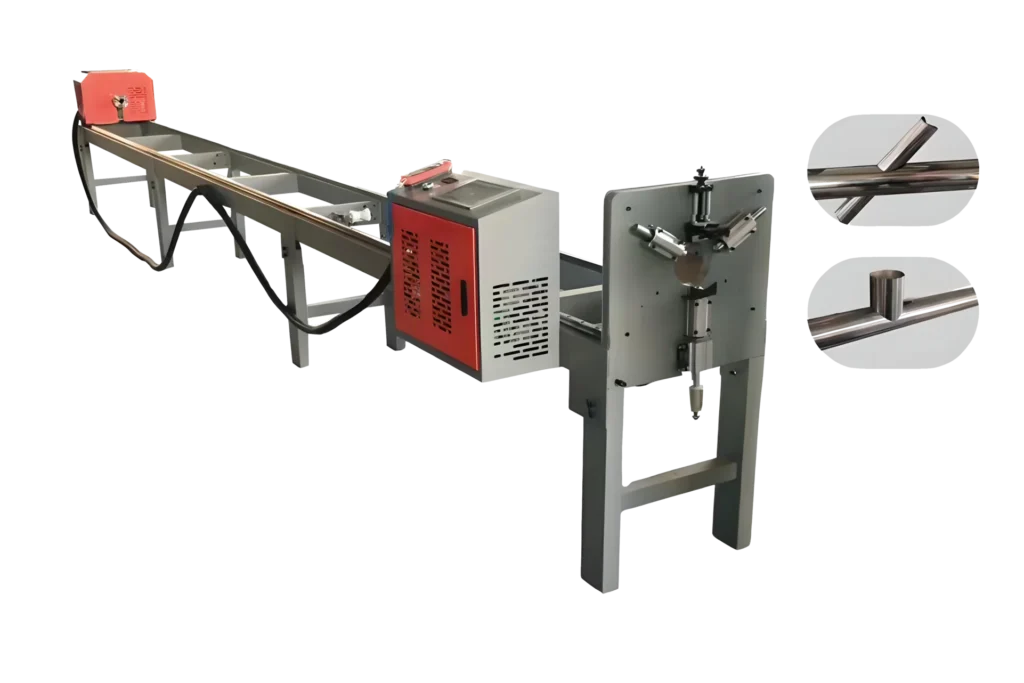

Portable CNC Pipe Cutting Machine for Fence Handrails | Easy and Efficient

Portable Plasma CNC pipe cutting machine, designed for cutting 19-97mm pipes in the fence and handrail industry. Lightweight and easy to transport, it delivers efficient plasma cutting without the need for drawings

Economical Square Tube Laser Cutting Machine | Versatile Laser Cutter for Multiple Profiles

Economical tube laser cutting machine, perfect for cutting 19-97mm Round Pipe and within 60mm diameter square tube, Features a high-resolution touchscreen for easy operation, precise cutting, and efficient material handling. Customizable to meet your needs.

Contact Us to Get A Quotation

Applicable Industry

With superior cutting processes and results, our types of equipment, the metal laser cutter, metal plasma cutter, and CNC tube cutter, are widely used in many different industries, such as Advertising Industry, Automobile Manufacture Industry, Gym Equipment Industry, Machine Manufacturing Industry, Medical Equipment Industry, Sanitary Tools Industry, Sheet Metal Cutting Industry, Steel Structure Industry, Steel-Wood Furniture Industry, Tower Industry, and many other areas that required metal cutting solutions.

Tower Industry

Steel Structure Industry

Machine Manufacturing Industry

Sheet Metal Cutting Industry

Gym Equipment Industry

Oil-Gas Pipeline

Factory Building

City Building

Automobile Manufacture Industry

Advertising Industry

Plasma Cutter Videos

3000*1500mm flat plasma cutting machine working situation

2 in 1 Laser plasma cutting machine

Big Gantry Plasma Cutting Machine

5 axis plasma tube pipe cutting machine

Big scale flat rotary plasma cutting machine

Big Round Pipe Plasma Cutting Machine max 2000 diameter

8 Axis Plasma Tube Cutting Machine

Desk Flat Rotary Plasma Cutting Machine

Round Pipe Plasma Cutting Machine

OEM Service

We can offer OEM service.

For the end user, we can design and offer the new styles of plasma cutting machine according to your exact materials’ styles, thickness, size and exact processing requirement, even the factory workspace, investment plan.etc.

For distributors, brand or importers, we can offer customized designs, including machine models, accessories, and unique working functions to meet the different market requirement.

No matter what’s your requirement for the new models of machine, our team will offer the strongest support to try to help you realize the dream.

How to Adopt Suitable Plasma Power Supply

Plasma power supply is the most core component of plasma cutting machine, which directly affects the cutting function. How to choose the right plasma power supply according to your actual work requirements? We will make decision from the cutting thickness and material, cut verticality requirements, cut roughness and surface effect requirements, whether you need to cut fine holes in four aspects.

The first point, cutting thickness and material.

The cutting thickness of different powers’ plasma power are different, and, like fiber lasers supply, the maximum cutting thickness can not be used for mass production, only used occasionally. Reference to different power plasma power cutting parameters and actual work performance, in the field of large-volume cutting of medium-thick plate, the domestic LGK plasma power cutting carbon steel, for example, cutting 10-15mm select 120A or 160A, cutting 15mm-20mm select 200A, cutting 20-30mm select 300A, cutting 30mm-40mm select 400A, cutting 40-300mm carbon steel select flame cutting head.

| Different Powers' Plasma Cutting Supply Technical Parameter | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chinese LGK Plasma Power Supply | ||||||||||||||||

| Power | LGK-63IGBT | LGK-120IGBT | LGK-160IGBT | LGK-200IGBT | LGK-300HD | LGK-400HD | ||||||||||

| Working Effect | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | ||||

| Carbon steel | 25mm | 15mm | 45mm | 25mm | 60mm | 30mm | 70mm | 35mm | 100mm | 0.3-50mm | 120mm | 1-60mm | ||||

| Stainless steel | 20mm | 12mm | 36mm | 20mm | 48mm | 24mm | 56mm | 28mm | 80mm | 40mm | 95mm | 48mm | ||||

| Aluminum | 15mm | 9mm | 27mm | 15mm | 36mm | 18mm | 42mm | 21mm | 60mm | 30mm | 72mm | 72mm | ||||

| Brass | 15mm | 9mm | 27mm | 15mm | 36mm | 18mm | 42mm | 21mm | 60mm | 30mm | 72mm | 72mm | ||||

| American Hypertherm Plasma Power Supply | ||||||||||||||||

| Power | Powermax45 SYNC | Powermax65 SYNC | Powermax85 SYNC | Powermax105 SYNC | Powermax125 | MAXPRO200 | XPR300 | HPR400XD | ||||||||

| Working Effect | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut | Max cut | Perfect Cut |

| Carbon Steel | 29mm | 16mm | 32mm | 20mm | 38mm | 20mm | 50mm | 22mm | 57mm | 30mm | 75mm | 35mm | 80mm | 50mm | 80mm | 50mm |

| Stainless Steel | 22mm | 12mm | 25mm | 15mm | 30mm | 16mm | 40mm | 18mm | 45mm | 24mm | 60mm | 25mm | 75mm | 50mm | 80mm | 45mm |

| Aluminum | 16mm | 10mm | 20mm | 12mm | 22mm | 12mm | 30mm | 15mm | 35mm | 18mm | 45mm | 25mm | 50mm | 25mm | 80mm | 45mm |

| Brass | 16mm | 10mm | 20mm | 12mm | 22mm | 12mm | 30mm | 15mm | 35mm | 18mm | 45mm | 25mm | 50mm | 25mm | 80mm | 45mm |

| Attention:Above technical parameter comes from LGK and Hypertherm website, Contains exaggerated elements, cannot take as the rule of adopting suitable power,please contact us ask for the exact suitable schemes |

||||||||||||||||

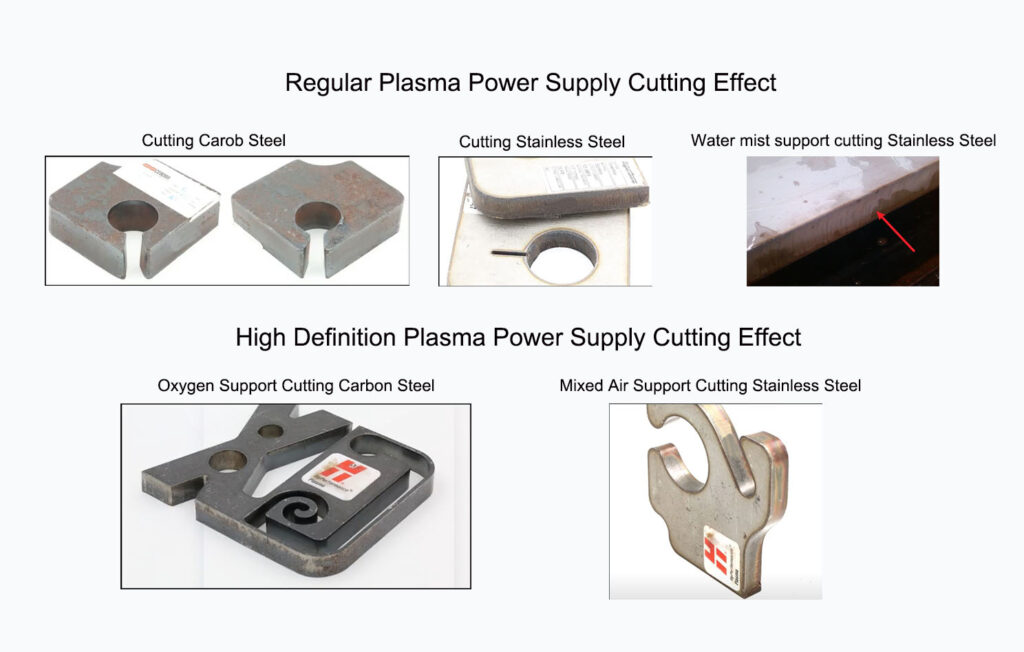

The second point, the requirement of verticality of the cut (precision)

Generally speaking, when cutting thick plates, the upper and lower perpendicularity error of regular air plasma power supply is 5°- 8°, and the cutting accuracy is about 1mm, and the upper and lower perpendicularity error of High definition plasma power supply is 1°-2°, and the cutting accuracy is about 0.5mm. If there is no high demand for verticality, as long as can cut is enough, then can adopt one cost-effective Chinese conventional air plasma power supply like LGK. However, if the requirement for cutting verticality is very high, then you can choose the USA imported Hypertherm plasma power supply or Chinese domestic LGK High definition plasma power supply.

Third Point, Requirements for roughness and effectiveness of the cutting surface.

Plasma power supplies can vary in cutting results depending on the type and technology. The following is a comparison of the cutting effect of several common plasma power sources:

1.Regular Air plasma power supply: Suitable for general metal material cutting, the kerf is wider, and the edge may have a certain degree of roughness, requiring subsequent grinding treatment.

2. High-definition plasma power supply(or Laser-like plasma power supply): By improving the torch design, the quality of the cutting surface is significantly improved, and the verticality of the edge can reach 0-1.5°, which is suitable for occasions with higher requirements on cutting quality.

Fifth point, if need to cut fine small holes。

Fine holes, also known as fine bolt holes, refers to the cutting of high quality round holes in mild steel with a 1:1 ratio of plate thickness to hole diameter in thicknesses ranging from 4mm to 30mm,one-time cut and shape, without the need for post-processing. This is a cutting process that is mainly used for processing high quality bolt hole workpieces. Eliminate the traditional processing process, after the completion of the cutting process, but also a separate drilling process, greatly improving production efficiency. But in the actual work process, want to achieve 1:1 is very difficult, in general, the plate thickness and hole diameter ratio is greater than 1:1.5 or more, you must choose the fine plasma power supply cutting (for example, in the 10mm plate, the processing of holes less than 15mm must be used in the fine plasma power supply). In addition, to cut fine small round holes, the choice of fine plasma power supply must be equipped with automatic gas control table, in addition to a small hole equipped with a tool library and support and plasma power communication system of high-precision bed, in addition to the need for compatibility with the system of automatic heightening system, and finally a set of small holes with a set of process library with a small hole library of the nesting software. In short, to cut fine small holes, the machine needs to be configured to a certain level. If the demand for cutting fine small round holes is not so large, it is not recommended to add more investment to choose these high accessories. Unless your processing volume is very large, and must need to cut small round holes, and then choose these configurations.

How to Choose the Suitable Plasma Cutting Machine Model?

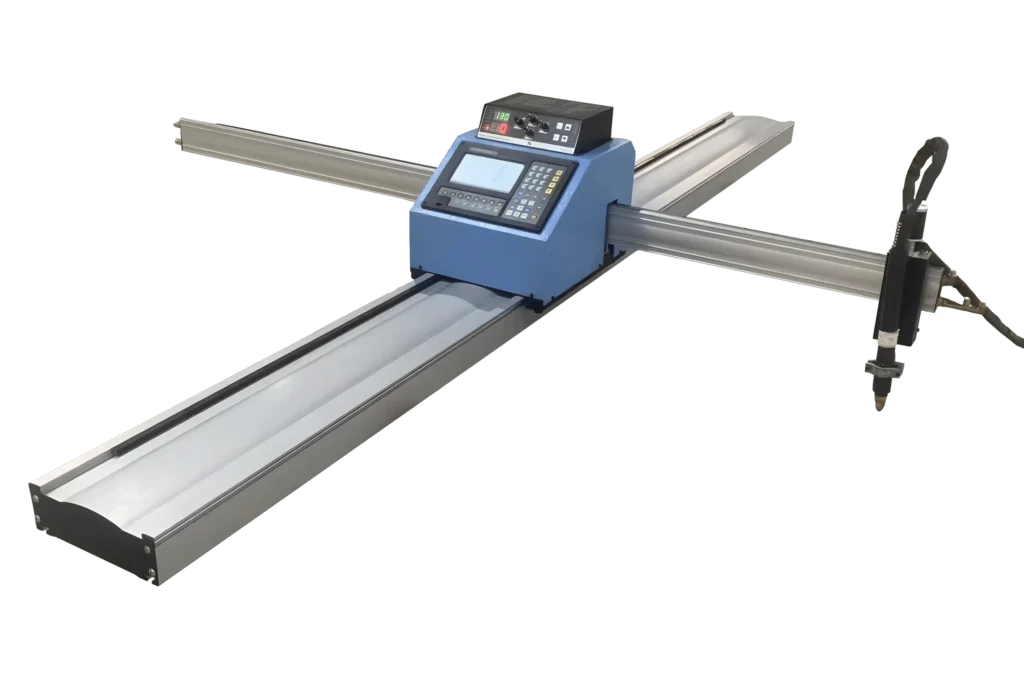

There are very many plasma cutter for sale on the market with complicated functions, but in general they are divided into four types, i.e. portable plasma cutting machine, tabletop plasma cutting machine, gantry plasma cutting machine and plasma tube cutter, what are the characteristics of each of them? Please refer to the following introduction.

The first model, the portable plasma cutter, is also called the Mini plasma cutter. This model is characterized by the majority working functions of plasma cutting machine can be completed, low price, light weight, easy to transport, easy to operate. At the same time, the disadvantages are also very obvious. First of all, the cutting speed is slow, the fastest cutting speed can reach 5-6m/min, it will lead to vibration if speed is too fast , will affecting the cutting effect; second is the accuracy, the accuracy of its work relative to the desktop plasma will be a little lower; Besides, customer need prepare the plasma cutting table by them selves; And finally, the working area is limited, the maximum width of the X-axis generally can not be more than 1.5 m. This type of plasma cutting machine is suitable to do a small batch of sheet metal cutting work! This type of plasma cutting machine is suitable for small batch of plate cutting work, which is often used in the start-up enterprises or the customers whose processing quantity is not so big. If the processing volume is large, for the speed requirements, easy to choose tabletop plasma cutter or gantry plasma cutting machine.

The second mode, desktop plasma cutting machine, is also the most common type of plasma models on the market. Its advantages are very obvious, the first is a fast cutting speed, the fastest can reach 55m/min with servo motors, or 25m/min with stepper motors; The second is the cutting accuracy is very high, it’s has the highest accuracy among all types of cnc plasma cutter, suitable for doing fine cutting; The third is the loading materials is very convenient, the general machine is equipped with auxiliary loading of the ball and roller, can manually push the material onto the platform. And because the machine itself is equipped with a worktable, customers do not need to prepare it, can be used directly. Of course, he also has its own shortcomings, the first is that the length of the machine’s X-axis is limited, generally can not exceed 2m, the Y-axis direction is generally the longest can not exceed 6m, or can only be used to splice the bed, but will affect the overall accuracy of the machine. Generally speaking, the X-axis is often done is 1.3m, 1.5m and 2m, the conventional model is generally 1.3 * 2.5m, 1.5 * 3m, 2 * 4m and 2 * 6m; The second point, because the worktable and the transmission system is a one-whole body, so not suitable for supporting heavy plate materials, generally speaking, the thickest plate can not be more than 30mm, or can lead to deformation of the bed.

The third model, gantry plasma cutting machine, also called floor rail plasma cutting machine. He is characterized by the follows point. Firstly, the cutting negative is very large, theoretically the X-axis direction can be done 8-10m, Y-axis direction is unlimited extension, especially suitable for cutting large-size plates, often do the model is generally 3 * 6m, 4 * 8m, 4 * 10m; The secondly , especially suitable for cutting medium-thick plates, because this equipment is the work platform and transmission guide rail separation design, so that even if the platform will be crushed by thick plate materials, will not affect the overall cutting accuracy and stability of the machine; The thirdly, the use of high-quality transmission system, for the working environment requirements are very low, do not fear of dust, iron filings, can be put into the outdoor work. The main disadvantages are, first, customers need to prepare their own cutting table; second, customers need to do a good job of foundation, the machine’s drive system also needs to be installed on the H-beam, the need to adjust the flatness, so the installation will be a little cumbersome. This kind of equipment is especially suitable for metal processing plants that need to process large-format medium-thickness plates, or the occasion of harsh outdoor working environment.

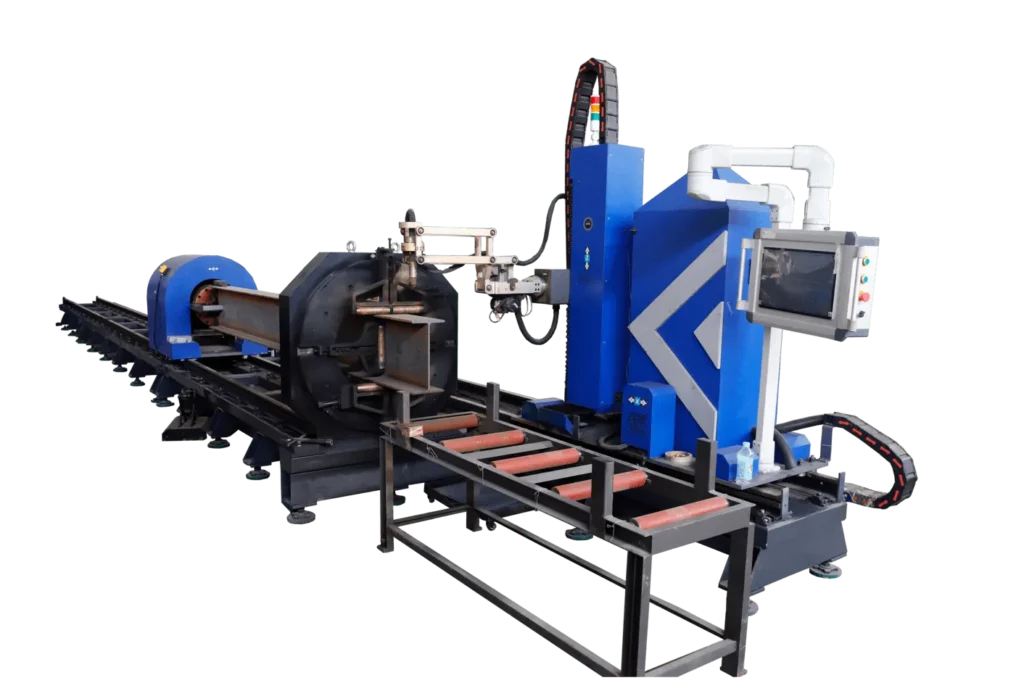

The fourth mode, pipe plasma cutting machine, including 5-axis square and round pipe plasma cutting machine, 8-axis plasma cutting machine,simple round pipe cutting machine and so on. This equipment is mainly used to cut square pipe, round pipe, H-beam, angle steel, profiled steel, I-beam and other pipes, according to the different types of pipe cutting and different configurations are divided into many models, but in general, it belongs to the plasma cutting machine’s high-end equipment.

Contact Us to Get A Quotation

How Much Does A CNC Plasma Cutter Cost?

According to the difference models, and accessories for plasma power supply, plasma head, driving system,control system,motor, driver,guild, machine frame.etc, that many points cause cnc plasma cutting machine price ranging are from $1500 to $100,000. No matter you are just purchase one simple machine for your start business, or raise the working efficiency or cutting effect for regular factory, always could find the most suitable models with affordable price. Below Price range for review, if need more exact quotation schemes, please contact us.

| Plasma Cutting Machine Price | |||

|---|---|---|---|

| Model | Minmum Price | Maxium Price | Average Price |

| Portabl Plasma Cutter | $1,500 | $8,800 | $2,500 |

| Desktop Plasma Cutter | $3,500 | $5,800 | $40,000 |

| Gantry Plasma Cutter | $9,000 | $58,000 | $15,000 |

| Pipe Plasma Cutter | $6,000 | $100,000 | $70,000 |

| Attention: According to the different models and accessory, the price has much big difference, above price are just for review, please contact us ask for the exact quotation |

|||

What Does Customer Say Us?

Are you still unsure about purchasing CNC machines from Light CNC Laser? The best way to gain confidence is by reading authentic testimonials from our actual customers. We regularly conduct satisfaction surveys, inviting our customers to provide honest feedback on our products and services. As you’ll see in the following reviews, many users have shared their personal experiences with our machines. Light CNC Laser gathers insights from customers based on their experiences with the CNC machines they have purchased, as well as their opinions on the buying process, repair, and maintenance services. We are committed to providing high-quality products and exceptional services, which motivates us to continually innovate and grow.

David Harrison

The steel laser cutter I bought from Light CNC Laser works perfectly! What impressed me the most was their after-service. The team was always ready to help, providing quick and efficient support whenever I needed it. Great experience overall!

Edward Collins

The best plasma cutter I purchased from Light CNC Laser arrived in incredibly strong packing. I was really impressed with the care they took in securing everything. It arrived in perfect condition, ready to work straight out of the box!

James Anderson

I purchased an industrial laser cutter from Light CNC Laser, and I couldn’t be happier with the quality. The machine is incredibly reliable and precise, and it’s made a huge difference in my production line. Truly top-notch equipment!

George Robinson

I had some technical questions after receiving my best plasma cutter, and the online support from Light CNC Laser was fantastic. They patiently walked me through everything, ensuring I got the most out of my new machine. I’m very satisfied!

Thomas Bennett

Light CNC Laser’s steel laser cutter has exceeded my expectations. The working effect is amazing, with clean, precise cuts every time. It’s clear that this machine was built with high standards. I’m thrilled with the results!

Stephen Brooks

Light CNC Laser’s metal plasma cutter is a solid machine, but what really stands out is their maintenance support. They’ve been there whenever I needed them, keeping my machine running smoothly. Their commitment to customer service is exceptional!

Charles Miller

I was worried about timing, but Light CNC Laser delivered my steel laser cutter right on schedule. The punctual delivery allowed me to meet all my deadlines without any stress. Absolutely dependable service

Franklin Morgan

As a first-time buyer, I was nervous, but the professional suggestions from Light CNC Laser’s team made all the difference. They guided me through the process, helping me choose the perfect laser cutting machine manufacturer for my needs. I couldn’t be more grateful

Service Area

All Over The World

Time Operasional

08.00 AM - 06.00 PM

Location

Jinan, China