Introduction

Selecting the appropriate laser power is critical for the performance and cost-effectiveness of a fiber laser cutting machine. Laser power significantly impacts cutting thickness, speed, quality, operating costs, and energy consumption. To meet diverse cutting demands across industries, factors such as material type, thickness range, production capacity requirements, and budget constraints must be systematically evaluated to tailor the laser power configuration to specific needs.

Fiber laser Cutting Machine

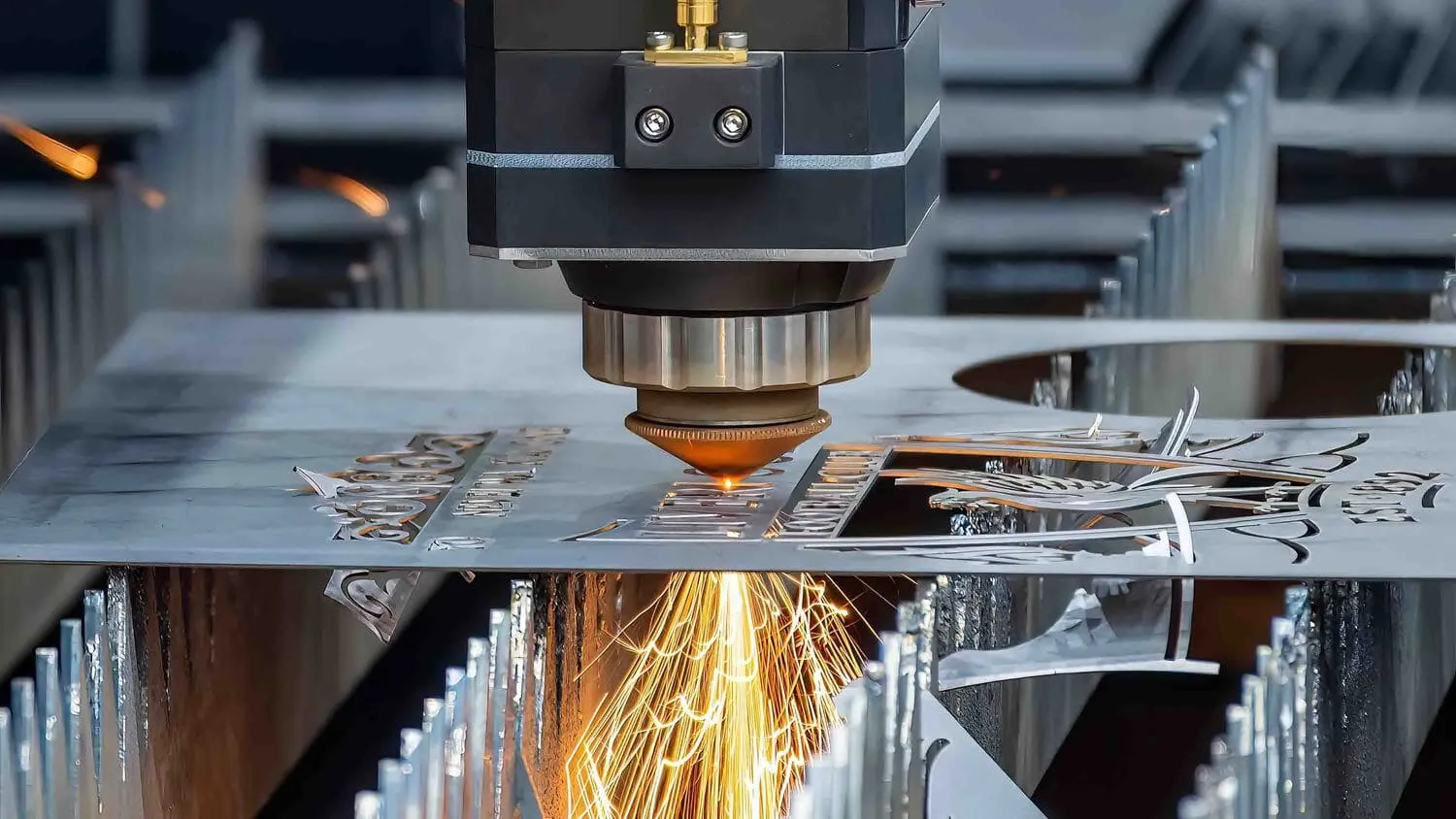

Relationship Between Power, Cutting Capacity, and Energy Consumption

Laser power directly determines the maximum material thickness and cutting efficiency. Higher power enables thicker material cutting and faster speeds. For example:

- A 3kW laser can cut up to 20mm-thick carbon steel (with oxygen assist) at 0.3–0.5 m/min.

- A 6kW laser cuts the same 20mm carbon steel at 0.5–0.8 m/min, and achieves 2.5–5.2 m/min for 12mm carbon steel.

However, higher power also increases energy consumption. For instance:

- A 2kW machine consumes ~6 kWh/hour.

- A 6kW machine with supporting equipment consumes up to 32 kWh/hour under high load.

Cutting Capacity by Power Level

| Laser Power | Cutting Capacity Overview | Typical Speed | Energy Consumption (kWh/hour) |

|---|---|---|---|

| 1.5kW | ≤12mm carbon steel, ≤6mm stainless steel | 6mm carbon: several m/min | 4–6 |

| 3kW | ≤20mm carbon steel, ≤10mm stainless steel | 10mm carbon: ~3 m/min | 10–12 |

| 6kW | ≤25mm carbon steel, ≤16mm stainless steel | 12mm carbon: 2.5–5.2 m/min | 30–40 |

| 12kW | ≤50mm carbon steel (special processes) | 25mm carbon: 0.5–1.2 m/min | 60+ |

Note: Speeds vary by material and process; values are for carbon steel with optimal gas.

Cutting Surface Quality for Carbon Steel

Laser power and assist gas selection affect surface quality:

- Bright Surface Cutting:

- Uses high-pressure nitrogen (prevents oxidation).

- Requires high power for thick materials (e.g., 12kW for 25mm carbon steel).

- Lower power (e.g., 3kW) limited to thin sheets (≤8mm).

- Gray Surface Cutting:

- Uses oxygen (exothermic reactions enable thicker cuts).

- Leaves oxidized surfaces; suitable for lower-power machines (e.g., 1.5kW cuts 12mm carbon steel).

Assist Gas Comparison

| Gas | Quality | Thickness & Speed | Cost | Applications |

|---|---|---|---|---|

| Oxygen | Oxidized, gray surface | Best for thick carbon steel | Low cost | Carbon steel (>8–10mm) |

| Nitrogen | Bright, oxidation-free | High quality for thin sheets | High cost | Stainless steel, aluminum, thin carbon steel |

| Air | Slight oxidation | Cost-effective for thin sheets | Very low cost | Low-cost thin sheets |

Note: Nitrogen requires high-pressure systems; air needs dry compressors.

Power, Material, and Gas Combinations

Carbon Steel (Low Carbon)

| Laser Power | Oxygen (Gray) | Nitrogen (Bright) | Air |

|---|---|---|---|

| 1.5kW | 12mm | 6mm | 6mm |

| 3kW | 20mm | 10mm | 8–10mm |

| 6kW | 25mm | 15–16mm | 12–15mm |

| 12kW | 50mm | 30mm | 25mm |

Stainless Steel (304/201)

| Laser Power | Nitrogen | Air |

|---|---|---|

| 1.5kW | 4–6mm | 3–4mm |

| 12kW | 40–50mm | 20–30mm |

Aluminum Alloy

| Laser Power | Nitrogen | Air |

|---|---|---|

| 1.5kW | 5mm | 4mm |

| 12kW | 30–50mm | 25mm |

Application Scenarios

-

Startups/Small Shops

- Profile: Low budget, thin sheets (≤6mm).

- Recommendation: 1.5–2kW with oxygen for carbon steel.

-

Medium-Scale Factories

- Profile: Mid-thickness batch production (e.g., 10mm carbon steel).

- Recommendation: 3–4kW with flexible gas options.

-

Large Factories

- Profile: High efficiency, diverse thicknesses.

- Recommendation: 6kW+ for high-volume production.

-

Heavy Industry

- Profile: Thick plates (>20mm).

- Recommendation: 8–12kW for precision cutting.

-

Future-Proofing

- Recommendation: Select slightly higher power (e.g., 3kW over 2kW).

Conclusion

Key principles:

- Demand-Driven: Match power to material and thickness.

- Balance Efficiency and Cost: Higher power = higher productivity but higher costs.

- Optimize Gas-Power Pairing: Ensure combinations meet quality needs.

- Consider Future Needs: Allow for scalability.

"The most expensive isn’t the best—the most suitable is."