Fiber laser cutting machines utilize high-power focused lasers to cut metal materials, featuring narrow kerfs and minimal Heat Affected Zones (HAZ), characterized by high precision and efficiency. Ultrafast fiber laser cutting achieves nearly heat-free cutting effects, producing metal parts with high precision and excellent surface quality. In emerging markets, as manufacturing and infrastructure upgrade, metal processing enterprises have a strong demand for automated, efficient cutting equipment, providing excellent opportunities for the import and sales of fiber laser cutting machines. For example, several Chinese laser equipment manufacturers have exported large quantities of cutting machines to countries such as Malaysia, Chile, Saudi Arabia, and Kenya, demonstrating local market recognition of Chinese brands.

Market Demand and Profit Margins: Industries like textiles, automotive, home appliances, and construction in emerging markets show growing demand for automated metal processing. Laser cutting, with its high efficiency and fine processing capabilities, can replace traditional stamping and cutting methods. Therefore, manufacturers are willing to pay a premium for higher productivity. When undertaking laser processing jobs, typical processing profit margins can reach 50%~60%. Based on typical operational scale calculations, a laser cutting machine can usually recoup its investment within 2-3 years with sufficient processing orders, yielding considerable profits in the long term.

Import and Sales Model: Distributors can acquire customers through import agency, exhibition marketing, online promotion, etc. Partnering with local metal processing plants, advertising sign manufacturers, etc., to provide complete machine sales and supporting services is a common model. Establishing strategic alliances with local partners helps quickly enter the market and resolve customs clearance and certification issues. Additionally, some Chinese companies set up factories or offices overseas for local production and marketing. For instance, Huagong, Hymson, and Guangfeng have established production bases in places like Vietnam and Thailand.

Success Cases: Many Chinese companies have made breakthroughs in Southeast Asian, African, and Latin American markets. For example, Xunlei Laser recently secured large orders for export to Southeast Asian countries, and Xin Quanli Laser products are sold to Chile, the Philippines, Saudi Arabia, Kenya, and other nations, further proving the international competitiveness of Chinese laser equipment.

Key Points for Choosing Manufacturers: When collaborating, priority should be given to qualified manufacturers with export experience, such as those holding ISO9001 and CE certifications. Representative Chinese brands include Jinan Xunlei (Light CNC Laser), among others. These manufacturers have mature technology and extensive experience, with their products widely used in billboards, steel structures, sheet metal processing, and other fields. Partnering with experienced manufacturers provides more stable quality assurance and comprehensive after-sales service, increasing project success rates.

Local Processing Production and Industry Entry

Purchasing fiber laser cutting machines for local production or undertaking processing jobs is also a common path for new entrants. Focusing on the following applications based on market demand and profit margins in different sectors is recommended:

Furniture Manufacturing: Steel-wood furniture, metal bed frames, cabinets, etc., require large quantities of customized metal parts. Fiber laser cutting machines cut materials like iron plates and stainless steel to produce complex-shaped furniture accessories. The furniture market has high demands for quality and customization; providing high-precision processing services can command higher premiums.

Automotive and Motorcycle Parts: Local automotive parts factories and modification workshops need to cut sheet metal parts, chassis brackets, etc. Laser cutting offers narrow kerfs and high precision, suitable for processing materials like cold-rolled steel and aluminum alloys.

===== Page 2 =====

Although the profit per piece might not be high, the order volumes are large, and product iterations are fast. Securing stable orders can still yield considerable total profits.

Sheet Metal Processing: Industries like machinery, electronic equipment, and cabinets require large quantities of sheet metal parts processing. Laser cutting has significant efficiency advantages for thin and medium-thick sheet metal. Undertaking local sheet metal processing allows leveraging existing metal supply resources to achieve stable gross profits under high capacity (reference outsourcing processing profit margin of 50%-60%).

Advertising Signage and Decoration Industry: There is continuous market demand for billboards, storefront signs, engraved decorative pieces, etc. Laser cutting can quickly produce metal signs with complex text and patterns to meet personalized needs. The advertising signage industry offers relatively high profits with many custom orders; businesses are usually willing to pay for high-quality cutting and fast delivery.

Architectural Decoration: Components like stainless steel guardrails, stair treads, and ceiling keels require precise processing. Laser cutting machines can efficiently process decorative metal parts, improving installation accuracy. With urbanization and growing renovation demands, the gross profit for such products is relatively substantial.

Agricultural Machinery and Other Heavy Industries: Parts for agricultural machinery, tractor frames, forklift buckets, etc., require cutting equipment capable of processing thick plates. Although single-piece volumes are large and profit margins relatively lower, orders can be taken in batches. Providing high-power laser cutting can shorten delivery cycles and help local manufacturers reduce production costs.

By focusing on the above industries and building a stable customer base, new entrants can leverage the technical advantages of fiber laser cutting to achieve rapid profitability.

Developing Value-Added Services

Beyond equipment sales and processing services, developing value-added services around fiber laser cutting machines is a crucial way to increase profitability:

Operator Training: Fiber laser cutting machines are technologically advanced, and customers generally require operational training after purchase. Offering professional training courses to help customers master programming, machine debugging, troubleshooting, etc., can generate training fees while increasing customer dependence on the equipment.

Installation and Commissioning: Machines require professional installation and commissioning upon arrival, including optical path calibration, parameter configuration, etc. Installation service is not only a value-added point but also lays the foundation for subsequent maintenance, enhancing customer satisfaction.

Maintenance and Repair: Laser cutting machines have ongoing maintenance needs, such as cleaning the light source cooling system, cleaning laser head lenses, lubricating/replacing belts/lead screws, etc. Establishing regular maintenance and rapid response mechanisms allows signing service contracts with customers, creating long-term stable income. Simultaneously, quality service deepens customer loyalty and increases opportunities for future upgrades or additional purchases.

Especially in emerging markets like Southeast Asia and Africa, language and technical support are critical. It is emphasized that localizing products and services – providing training and technical support in local languages – is key to winning customer trust. Therefore,

new entrants can collaborate with Chinese manufacturers or local technical service providers to introduce factory trainers or certified technicians to penetrate the market with professional services.

Technical Features and Pricing of Chinese Equipment

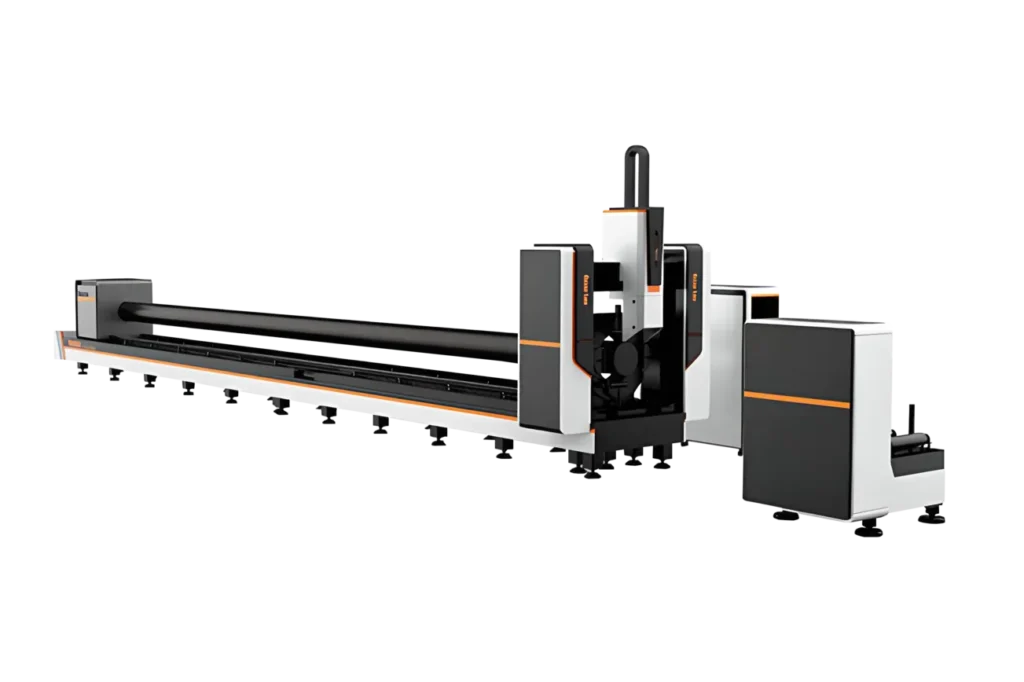

Currently, domestically produced fiber laser cutting machines are renowned for their high cost-performance ratio. Technologically, Chinese manufacturers widely adopt stable and mature fiber lasers (such as domestically produced 10,000-watt class fiber lasers) and high-precision motion control systems, significantly improving cutting accuracy and stability. Compared to similar foreign products, Chinese models have significant price advantages in basic configurations. Price-wise, based on market data, fiber laser cutting machines typically range from tens of thousands to over one hundred thousand US dollars (equivalent to hundreds of thousands to millions of RMB). Low-power 1-kilowatt class models start at tens of thousands of RMB, while multi-kilowatt high-power models can reach hundreds of thousands or even millions of RMB.

China has become one of the world’s largest producers and exporters of fiber laser cutting machines. For example, Light CNC Laser (Jinan Xunlei Laser) is a representative Chinese brand. Established for 15 years, its product range covers various models for sheet metal and tube cutting. Its official website states that the company’s equipment is widely used in industries like advertising, steel structures, and engineering machinery, gradually becoming a world-renowned CNC brand. Additionally, leading manufacturers like Huagong and Raycus have leading technological levels, continuously launching new models with higher power and greater automation, solidifying their industry positions. Regarding price range, domestic laser machines are often more than 50% cheaper than European and American brands, leaving overseas distributors significant profit margins.

In summary, Chinese fiber laser cutting machines dominate the global market with their "high volume and competitive pricing" advantage, making them suitable for new entrants looking to replicate local production or start processing businesses.

Future Industry Trends

In the future, the fiber laser cutting machine industry will continue to develop towards higher power, higher automation, and intelligence. On one hand, higher-power fiber lasers (e.g., 20kW, 40kW class) can cut thicker metal plates, enabling high-speed production. Ultrafast laser technology and "green" laser sources are also advancing: ultrafast sources enable extremely narrow kerfs and virtually heat-free cutting; green lasers can efficiently cut highly reflective materials like copper, expanding new application fields for laser cutting. On the other hand, automated integration applications are maturing. Future factories may widely adopt technologies like robotic loading/unloading, AI-optimized cutting parameters, and cloud platform data monitoring to achieve intelligent production processes. Predictive maintenance (using big data and AI to anticipate equipment failures) will also become commonplace, improving production continuity and reducing operating costs. With the advancement of Industry 4.0, the deep integration of fiber laser cutting machines with digitalization and smart manufacturing will also provide more value-added application scenarios for the equipment.

In conclusion, the opportunity has arrived: emerging markets are accelerating the release of demand for advanced cutting technology. Early movers with technological advantages and market sensitivity will gain a first-mover advantage. Taking immediate action to seize this lucrative moment in the laser cutting machine industry will bring new growth points for your enterprise!