Tube Pipe Cutting Machines: Fiber and Plasma Solutions for All Tube Types

What Is CNC Pipe Cutter?

Cnc pipe cutter is one special type of metal cutting machine, it only used to cutting various metal tube materials, like square tube, round pipe, H-shape tube, V-shape tube, I-shape tube, and Special-shaped pipe.etc. It divide into fiber laser pipe cutting machine and plasma pipe cutting machine according cutting styles. According to the exact working functions and controller, laser power supply or plasma power supply, cutting head, motor, driver, machine frame, size.etc, many more different models of cnc pipe cutter come out. No matter you just want to purchase one entry-level styles to cut round pipe, or plan to purchase professional high-accessory models to raise working efficiency, or use it to cut more bigger size pipe, all could find the suitable styles in our factory.

Versatile Tube Pipe Cutting Machines for Round, Square, and Custom Profiles

CNC Tube Cutting Machines are specialized equipment in the fiber laser cutter and plasma cutter categories, designed for tube and pipe processing. Available in various models, they handle round, square, H-shaped, and custom-shaped tubes with high precision. Depending on material size and efficiency needs, you’ll find a range of options to suit your requirements. Explore competitive tube laser cutting machine prices and advanced fiber laser tube cutting machines to CNC plasma tube cutters tailored to your projects.

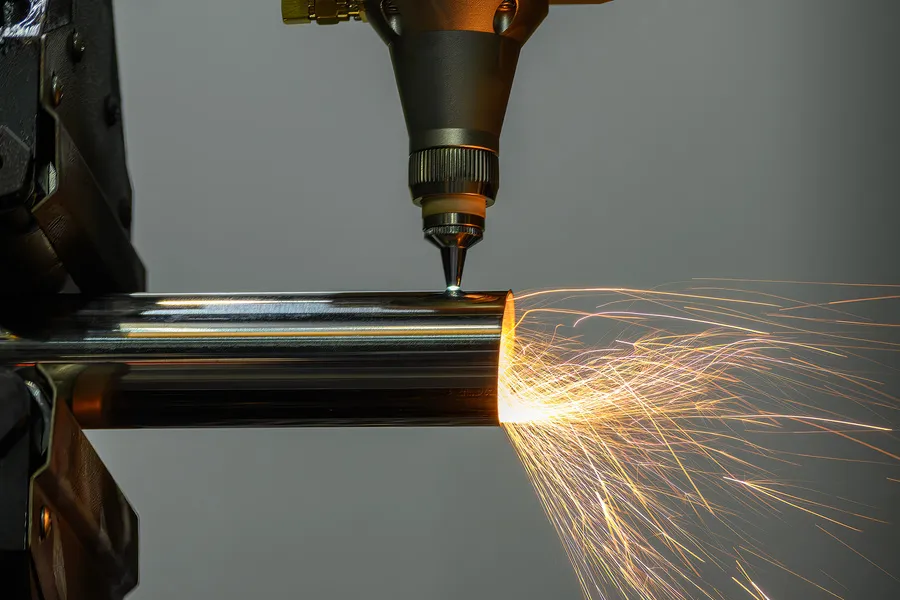

Laser Pipe Cutting Machine

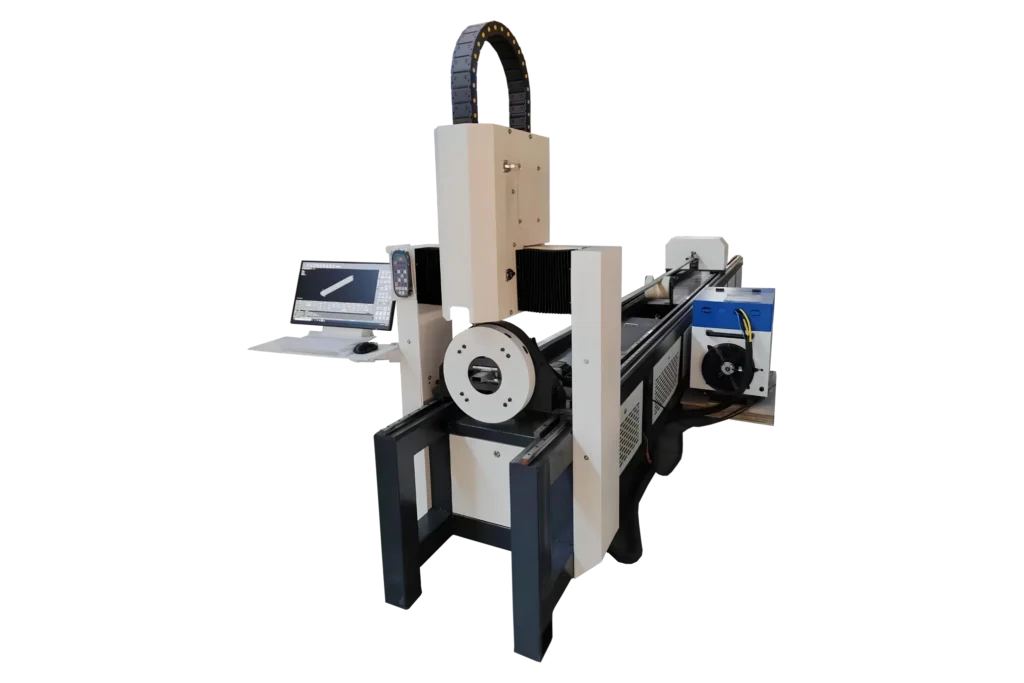

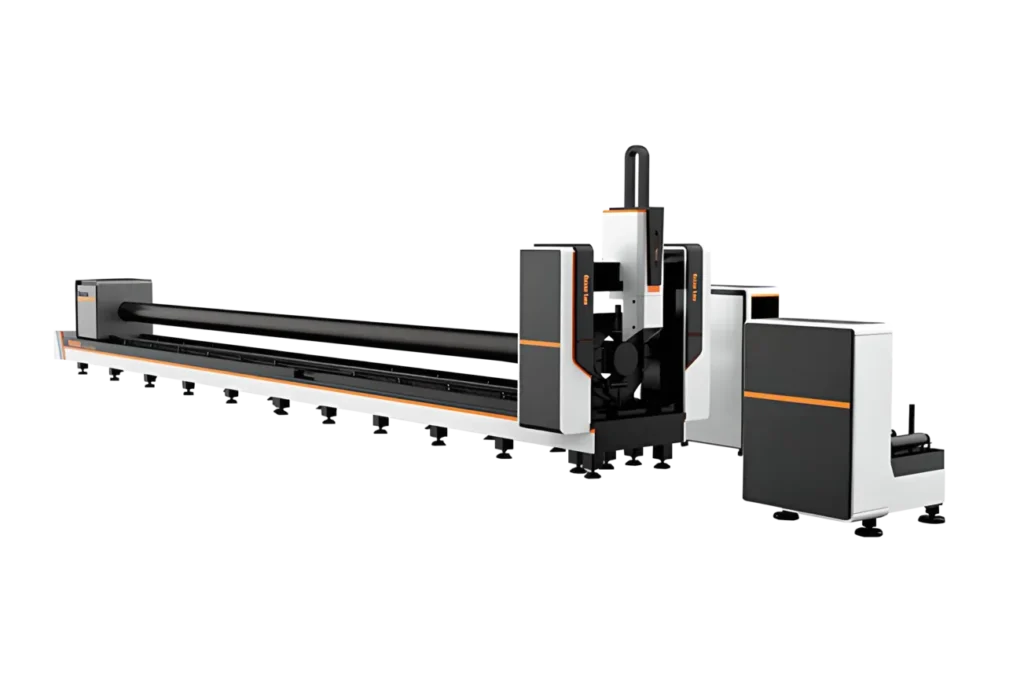

Industry-Leading 5-Axis Tube Laser Cutting Machine | High-Precision Fiber Laser Cutter

5-axis tube laser cutting machine, designed for precision cutting of pipe, tubes, H-beam. etc. Hand profiles up to 800mm diameter and 12000 mm length. Though two chucks but can work as Three Chucks Cutter

Plasma Pipe Cutting Machine

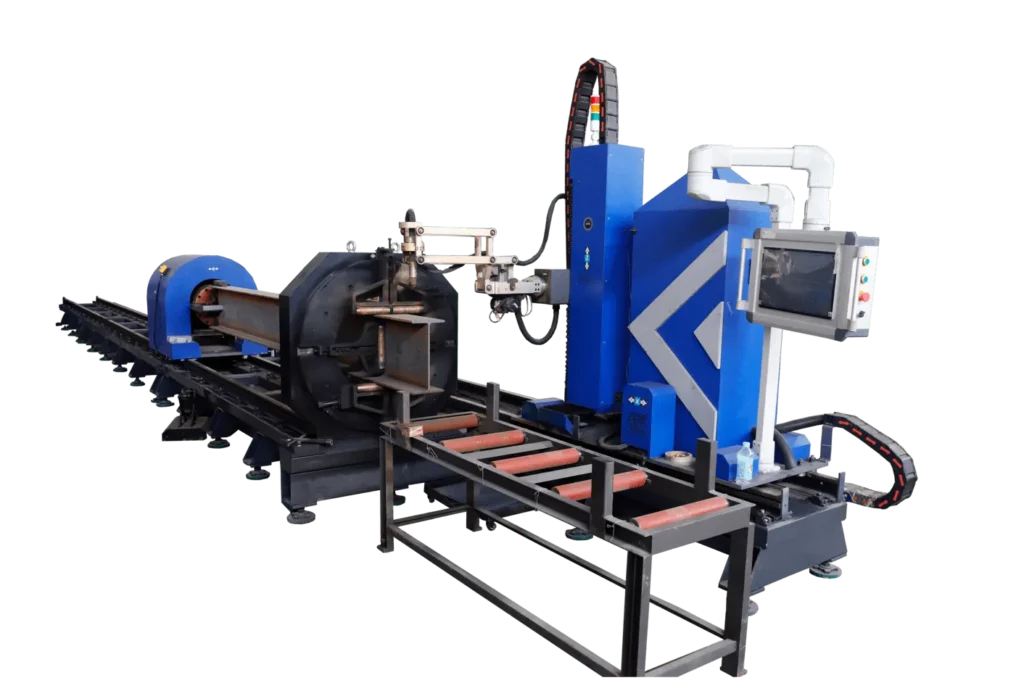

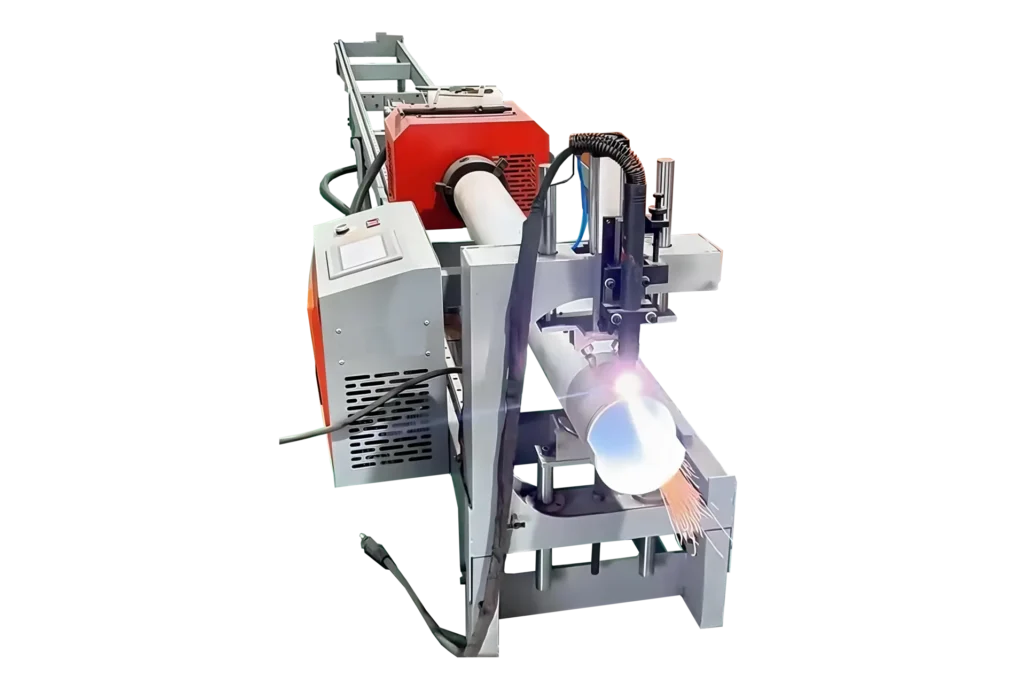

5-Axis CNC Plasma Tube Profiling Machine | Versatile Plasma Cutter for Pipes

CNC plasma tube profiling machine, Machine Beam is movable, can cut longger tube which finished products over 3 meters like three chucks laser tube cutter. Max process materials’ diameters up to 800mm, 12000mm length

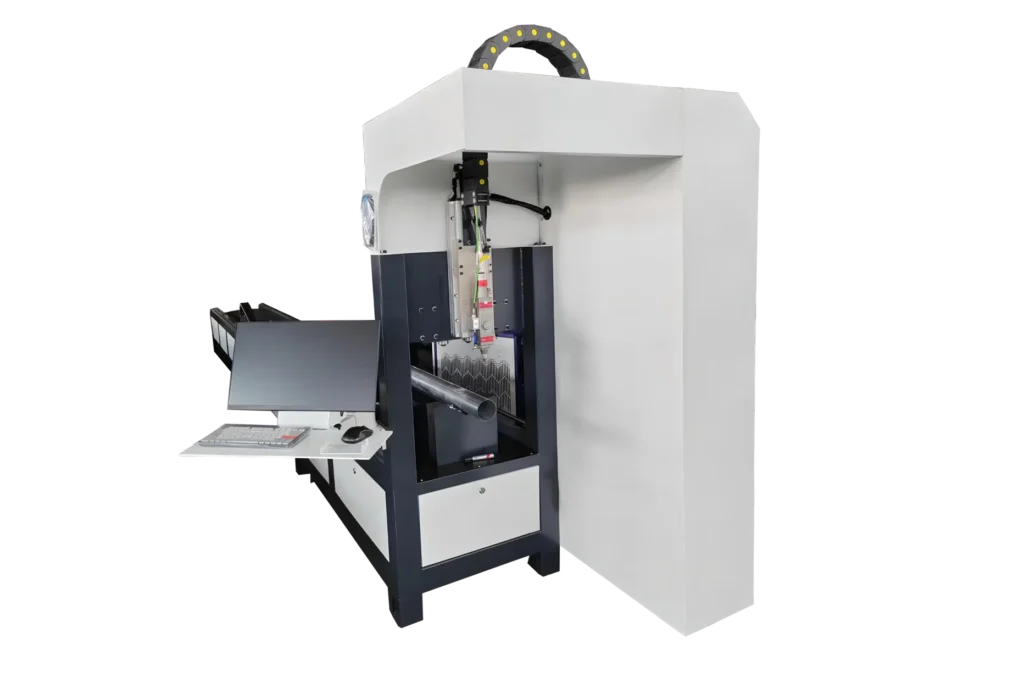

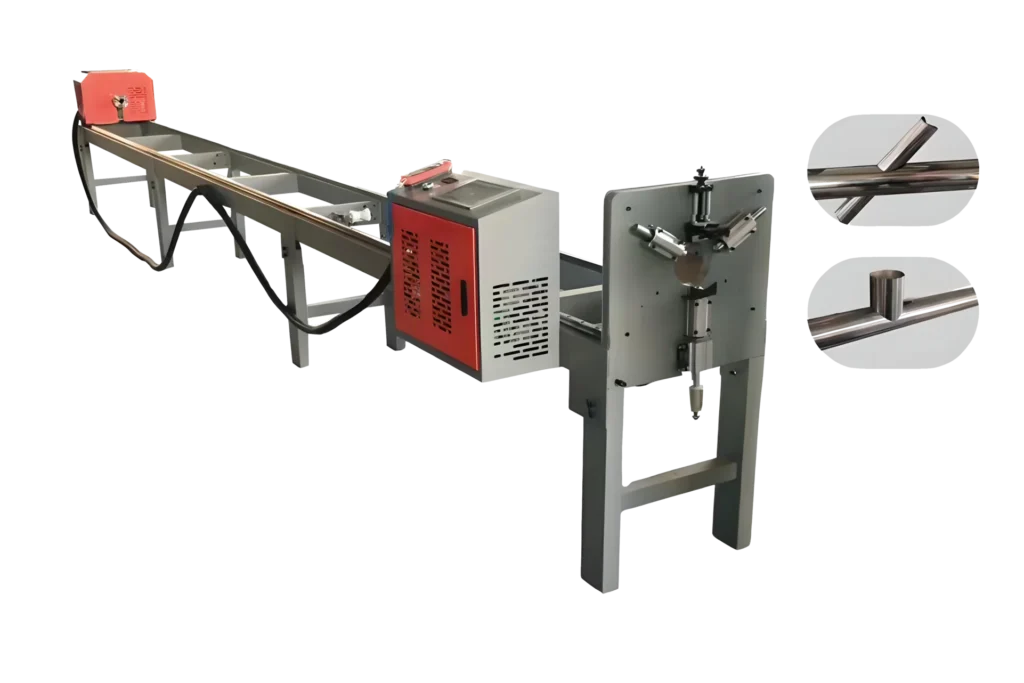

Economical Square Tube Laser Cutting Machine | Versatile laser Cutter for Multiple Profiles

Economical tube laser cutting machine, perfect for cutting 19-97mm Round Pipe and within 60mm diameter square tube, Features a high-resolution touchscreen for easy operation, precise cutting, and efficient material handling. Customizable to meet your needs.

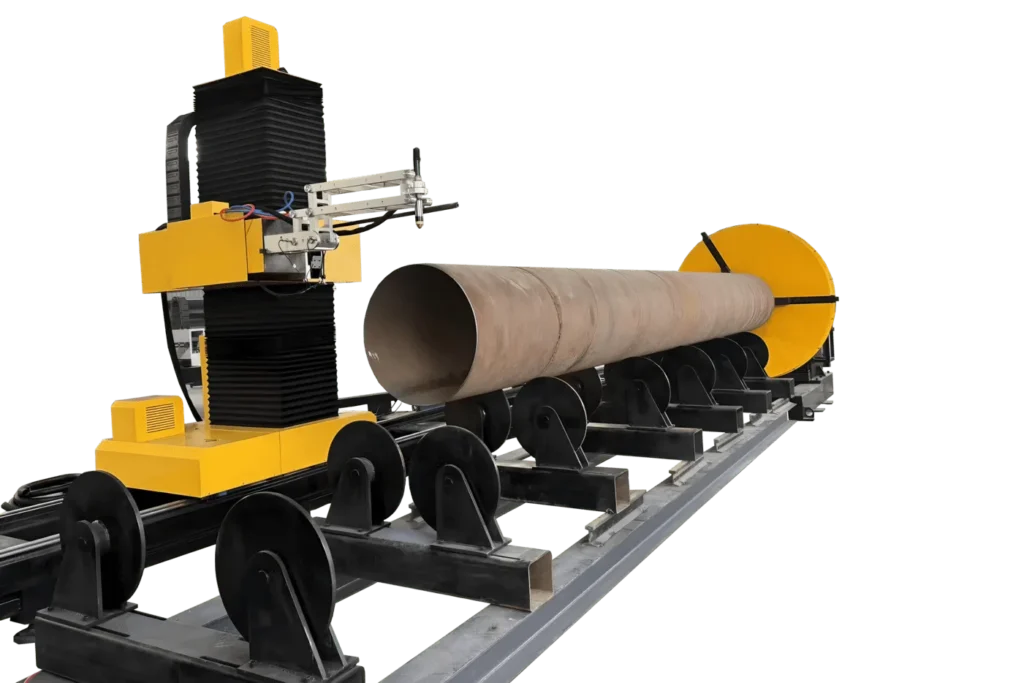

Affordable CNC Plasma Pipe Cutting Machine | Simple Tube Cutter for Round Pipes

Affordable CNC plasma pipe cutting machine, designed for easy cutting of round pipes with diameters from 50-219mm. Simple operation with electric chuck for auto clamping, ideal for various materials and low-cost, efficient cutting.

Portable CNC Pipe Cutting Machine for Fence Handrails | Easy Operate and High Efficient

Portable Plasma CNC pipe cutting machine, designed for cutting 19-97mm pipes in the fence and handrail industry. Lightweight and easy to transport, it delivers efficient plasma cutting without the need for drawings

OEM Service

We can offer OEM service.

For the end user, we can design and offer the new styles of fiber laser cutting machine according to your exact materials’ styles, thickness, size and exact processing requirement, even the factory workspace, investment plan.etc.

For distributors, brand or importers, we can offer customized designs, including machine models, accessories, and unique working functions to meet the different market requirement.

No matter what’s your requirement for the new models of machine, our team will offer the strongest support to try to help you realize the dream.

CNC Plasma and Laser Tube Cutting Machine Videos

5 Axis Tube Laser Cutting Machine Cut Channel Steel, Angle Steel, Round Pipe

3 Chucks Laser tube cutting machine Cut H-shape Steel

2 Chucks Laser tube pipe Cutting machine with auto loading system

5 Aixs Laser tube Cutting Machine cut Bevel

Heavy-duty Plasma Pipe Cutting Machine Cut big Round pipe

5 Axis Plasma Tube Cutting Machine cut square tube

CNC Plasma Pipe Cutting Machine Cut round pipe

8 Axis Plasma Cutting Machine Cut square tube, H-shape steel.etc

Metal Tube Pipe Products Samples

Applicable Industry

With superior cutting processes and results, our types of equipment, the metal laser cutter, metal plasma cutter, and CNC tube cutter, are widely used in many different industries, such as Twoer Industry, Steel Structure Industry, Machine Manufacturing Industry, Metal Tube Cutting Industry, Gym Equipment industry, Medical Equipment Industry, Sanitary Tools Industry, Sheet Metal Cutting Industry, Steel Structure Industry, Steel-Wood Furniture Industry, New Energy, Elvator, Aerospace, Oil-Gas Pipeline, City Building, Factory Building and many other areas that required metal cutting solutions.

Tower Industry

Steel Structure Industry

Machine Manufacturing Industry

Metal Tube Cutting Industry

Gym Equipment Industry

Steel-Wood Furniture Industry

Elevator

Sanitary Tools Industry

Aerospace

Medical Equipment Industry

Oil-Gas Pipeline

New Energey

City Building

Advertising Industry

Factory Building

Contact Us to Get A Quotation

What is the Difference Between Tube Plasma and Laser Cutting Machine

Working Principle

Tube Plasma Cutting Machine: By heating the gas (usually argon or compressed air) to a very high temperature, turned into a plasma state. Then, the plasma gas jetted at high speed melts the material to be cut, thus realizing the cutting purpose.

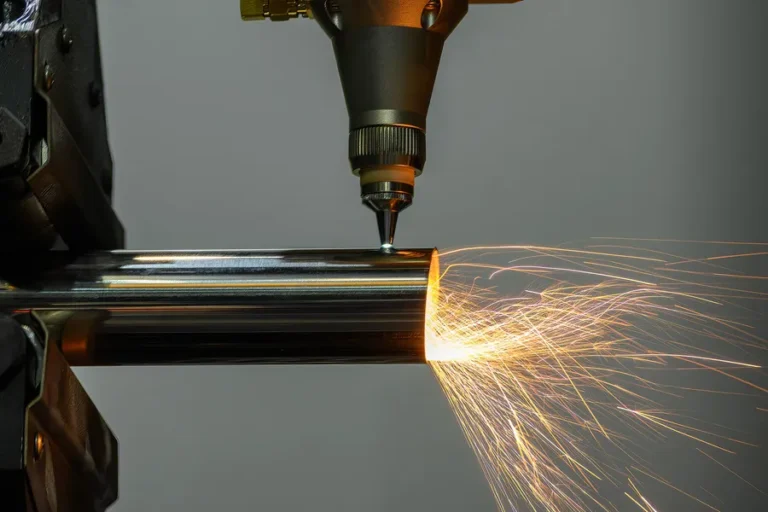

Laser Pipe Cutting Machine: By focusing a high power laser beam, the metal material is melted and vaporized. The high-energy laser beam can be accurately focused on the cutting line to finally realize cutting.

Cutting effect and precision

Plasma Pipe Cutter: Since plasma cutting machine uses high temperature plasma gas for cutting, more heat may be generated during the cutting process, resulting in melting and deformation of the cutting edge. As a result, the cutting accuracy of plasma cutters is relatively low and the cutting range is limited. Generally speaking, the cutting accuracy of plasma pipe cutter is between 1 – 2mm, while the accuracy of cnc laser pipe cutting machine can reach 0.1 – 0.3mm.

Metal Pipe Laser Cutting Machine: Laser cutting machine can realize high precision and high quality cutting effect. Compared with cnc plasma pipe cutting machine, laser cutting machine has smooth and burr-free cutting edges, smaller cutting line width and higher processing precision.

Cutting Speed and Efficiency

Plasma Pipe Cutting Machine: Plasma cutting machine has faster cutting speed when dealing with thick metal materials. Due to higher cutting speeds and lower equipment costs, plasma cutters have an advantage in mass big thickness and diameter’s tube production environments.

Tube Laser Machine: While cnc and laser cutting may have slightly lower cutting speeds than plasma cutters when working with thick metal materials, but laser cutters are faster and more efficient when working with thin metal materials.

Range of Cutting Materials

Both tube plasma cutting machine and fiber laser pipe cutting machine can cut metal materials such as copper, aluminum, stainless steel, and carbon steel. However, plasma pipe cutters offer better performance when cutting highly reactive materials such as copper and aluminum, while laser pipe cutters can be risky when cutting thicker, highly reactive materials.

Working environment

Plasma pipe cutters have relatively low requirements for the working environment and can work in a variety of complex factory environments or even outdoors.

Laser pipe cutting machine for the working environment requirements are relatively high, need to regularly clean up the body, laser head of the dust. And for high power laser machine, need to specially configure the air-conditioned room for the laser power source.

Cost and maintenance

Plasma Pipe Cutting Machine Price: the equipment cost of plasma cutting machine is relatively low. However, due to its cutting process consumes more electricity, so the running cost will be higher.

Laser Pipe Cutting Machine Price: The equipment cost of laser cutting machine is relatively high. However, due to its high cutting precision and small heat-affected zone, the degree of wear and tear of the equipment is relatively low, and the maintenance cost is relatively low.

Application Scenario

Plasma Pipe Cutting Machine: It is mainly used in mass production environment, such as steel structure manufacturing, machining and other fields. For some thick metal material cutting which does not require high cutting accuracy, plasma pipe cutter has high cost performance.

Laser pipe cutting machine: mainly used in high-precision processing areas, such as aerospace, medical equipment, electronic products manufacturing. For some complex geometric shapes and fine structure cutting, laser tube cutting machine has obvious advantages. Now with the development of technology, three chucks, four chucks of large laser tube cutting machine makes the tube laser machine in the processing of heavy large size pipe field also highlights the great advantage.

In general, plasma pipe cutting machine and laser pipe cutting machine have their own advantages and disadvantages, the enterprise should choose the right equipment according to their own production needs and budget . If there are related needs, welcome to contact us, we will recommend the most suitable scheme for you according to actual situation.

Tube Laser And Plasma Cutting Machine Price

CNC Tube Cutting Machine have many different models for various processing requirement. From the regular round pipe cutter to higher accessory three chucks laser tube cutter, the price will be much different. We could offer the entry – level styles to reduce your budget, also can offer high-cost performance models and high-end professional models to raise your working efficiency. Below is one approximate price list for review, if need exact offer, please contact us to offer more details about your tube materials, process requirement.

| CNC Tube Cutting Machine Price | ||||

|---|---|---|---|---|

| Machine Modes | Min Price | Max Price | Average Price | |

| Laser Tube Cutter | Round Pipe Laser Cutting Machine | $11,000 | $30,000 | $18,000 |

| 2 Chucks Tube Laser Cutting Machine | $17,000 | $44,000 | $25,000 | |

| 5 Axis Laser Tube Cutting Machine | $40,000 | $72,000 | $115,000 | |

| 3 Chucks Tube Laser Cutting Machine | $60,000 | $250,000 | $120,000 | |

| Plasma Tube Cutter | Round Pipe Plasma Cutting Machine | $4,000 | $20,000 | $14,000 |

| Tube Pipe Plasma Cutting Machine | $13,000 | $40,000 | $24,000 | |

| 5 Axis Plasma Tube Cutting Machine | $28,000 | $70,000 | $35,000 | |

| 8 Axis Plasma Tube Cutting Machine | $42,000 | $85,000 | $50,000 | |

| Large-Scale Pipe Plasma Cutter | $43,000 | $58,000 | $68,000 | |

| There price are just for review, the machine's final offer will be different according to processing materials, thickness, diameter, length, cutting effect, please contact us ask for exact schemes for your business work. |

||||

What Does Customer Say Us?

Are you still unsure about purchasing CNC machines from Light CNC Laser? The best way to gain confidence is by reading authentic testimonials from our actual customers. We regularly conduct satisfaction surveys, inviting our customers to provide honest feedback on our products and services. As you’ll see in the following reviews, many users have shared their personal experiences with our machines. Light CNC Laser gathers insights from customers based on their experiences with the CNC machines they have purchased, as well as their opinions on the buying process, repair, and maintenance services. We are committed to providing high-quality products and exceptional services, which motivates us to continually innovate and grow.

David Harrison

The steel laser cutter I bought from Light CNC Laser works perfectly! What impressed me the most was their after-service. The team was always ready to help, providing quick and efficient support whenever I needed it. Great experience overall!

Edward Collins

The best plasma cutter I purchased from Light CNC Laser arrived in incredibly strong packing. I was really impressed with the care they took in securing everything. It arrived in perfect condition, ready to work straight out of the box!

James Anderson

I purchased an industrial laser cutter from Light CNC Laser, and I couldn’t be happier with the quality. The machine is incredibly reliable and precise, and it’s made a huge difference in my production line. Truly top-notch equipment!

George Robinson

I had some technical questions after receiving my best plasma cutter, and the online support from Light CNC Laser was fantastic. They patiently walked me through everything, ensuring I got the most out of my new machine. I’m very satisfied!

Thomas Bennett

Light CNC Laser’s steel laser cutter has exceeded my expectations. The working effect is amazing, with clean, precise cuts every time. It’s clear that this machine was built with high standards. I’m thrilled with the results!

Stephen Brooks

Light CNC Laser’s metal plasma cutter is a solid machine, but what really stands out is their maintenance support. They’ve been there whenever I needed them, keeping my machine running smoothly. Their commitment to customer service is exceptional!

Charles Miller

I was worried about timing, but Light CNC Laser delivered my steel laser cutter right on schedule. The punctual delivery allowed me to meet all my deadlines without any stress. Absolutely dependable service

Franklin Morgan

As a first-time buyer, I was nervous, but the professional suggestions from Light CNC Laser’s team made all the difference. They guided me through the process, helping me choose the perfect laser cutting machine manufacturer for my needs. I couldn’t be more grateful

Service Area

All Over The World

Time Operasional

08.00 AM - 06.00 PM

Location

Jinan, China