Fiber Laser Tube Cutting Machine Selection Guide

As an engineer with ten years' experience, this article will analyze how to reasonably choose fiber laser tube cutting machine from a professional point of view. We will introduce the main model categories and their structural principles, performance index comparison, their respective advantages and disadvantages, as well as the application of different industries to analyze the suitability. Finally, we will give advice on selection according to different user needs and provide a general technical overview of fiber laser tube cutting (cutting principle, control system, evolution of clamping structure, etc.) for internal training and customer communication.

Laser tube Cutting Machine

1. Main Types and Working Principles of Fiber Laser Tube Cutting Machines

Fiber laser tube cutting machines can be divided into several types based on their structure and functionality. These include two-chuck tube cutting machines, three-chuck tube cutting machines, automatic feeding tube cutting machines, integrated sheet and tube laser cutting machines, specialized non-standard tube cutting machines, and heavy-duty tube cutting machines. Each type has its own features in terms of clamping methods, mechanical structure, and applicable scenarios. The following sections introduce the structural characteristics and working principles of these machines.

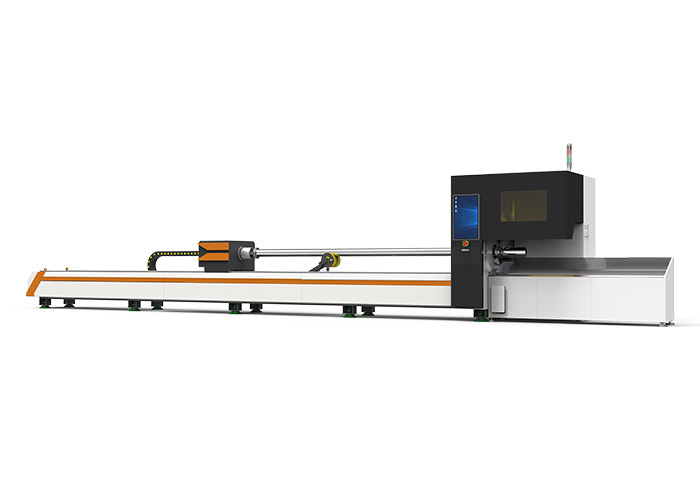

1.1 Two-Chuck Tube Cutting Machine

Two-Chuck Tube Cutting Machine

The two-chuck tube cutting machine is the most common basic model. It clamps the two ends of the tube using a front chuck and a rear chuck. In a typical configuration, one chuck is fixed at the front of the machine while the other is mounted on a movable carriage for feeding and positioning the tube. During cutting, the tube is held firmly by the chucks and is allowed to move axially and rotate about its own axis. The laser cutting head then aligns with the tube and performs the cutting process

(170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine)

(170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine).

Its working principle is to control the laser head and the rotation/feeding of the tube synchronously via a CNC system. The high-energy fiber laser beam is focused onto the tube wall to instantaneously melt or vaporize the material, and high-pressure assist gas is used to blow away the molten slag, thereby cutting the tube along the programmed trajectory.

Structural Features:

The two-chuck machine typically employs one fixed chuck (usually on the same side as the laser head) and one movable chuck to clamp the other end. During processing, a certain length of tube (tail material) must be reserved for the clamping action; thus, after cutting, several tens of millimeters of material may remain unused.

Working Principle:

The tube is clamped at two points and is allowed to rotate. The laser head, which usually has X and Y (or Z for vertical movement) adjustments for focus and positioning, directs a continuous laser beam onto the tube. For example, when cutting a hole or profile on a round tube, the tube rotates while moving axially, and the laser beam melts the metal; the assist gas removes the molten material, resulting in a neat, smooth cut.

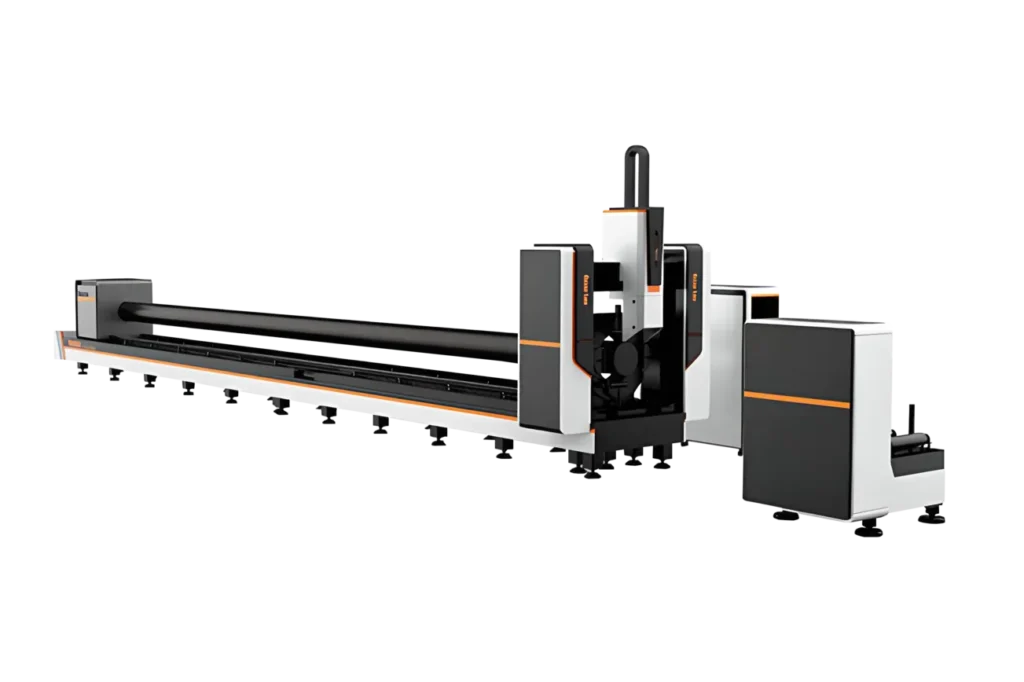

1.2 Three-Chuck Tube Cutting Machine

Three-Chuck laser tube cutting machine

A three-chuck tube cutting machine builds upon the two-chuck design by adding a third chuck to support and clamp the middle section of long tubes. In a typical structure, there are two chucks at the ends of the machine and an additional movable chuck in the middle, forming a “three-point clamping” system. The three chucks coordinate their movements during cutting; by alternately clamping the tube, the machine can achieve “pull-cutting” so that almost the entire tube length is used and tail material waste is minimized

(China CNC Three chuck Fiber Laser Tube Cutting Machine Manufacturers).

For example, when the tube is near its end, the middle chuck clamps the tube first, allowing the end chuck to release and reposition to take over, thus cutting off what would normally be considered waste. The three-chuck design can also correct tube deflection in long tubes, thereby improving cutting accuracy

(Three-chuck Heavy-duty Tube Laser Cutter | Senfeng USA).

Structural Features:

All three chucks are designed with full stroke and can be dynamically adjusted according to the tube length, providing simultaneous support and clamping at both ends and the middle

(TP Series Three Chucks Laser Tube Cutting Machine | XT LASER)

(TP Series Three Chucks Laser Tube Cutting Machine | XT LASER).

It generally employs a 7-axis CNC system (with an extra axis for the middle chuck), requiring an advanced bus control system to synchronize the three chucks

(China CNC Three chuck Fiber Laser Tube Cutting Machine Manufacturers).

These machines often feature an automatic follow-up support device to prevent sagging of slender tubes. By allowing the clamping position to shift during cutting, the entire tube can be processed without reserving extra tail material.

Working Principle:

The cutting principle of the three-chuck machine is similar to that of the two-chuck machine, but with an additional clamping point. The CNC system controls the sequence of releasing and clamping the three chucks according to the cutting progress. For example, initially the front and rear chucks clamp the tube; as the cut approaches the tail end, the middle chuck clamps the tube, then the rear chuck releases and repositions to continue clamping. This cyclic process ensures that the tube is always held by at least two chucks, allowing continuous cutting. The coordinated movement and tensioning of multiple chucks also improve stability and accuracy when cutting long tubes.

1.3 Automatic Feeding Tube Cutting Machine

Automatic Feeding Tube Cutting Machine

An automatic feeding tube cutting machine is equipped with an automated loading/unloading system. Its core cutting part is usually still based on a two- or three-chuck structure, but it is augmented with a magazine, robotic arm, or feeder rack to enable continuous tube feeding and finished-product unloading.

Structural Features:

It generally includes a storage magazine that holds multiple tubes. The feeder automatically delivers tubes one by one into the clamping area, and after cutting, an automatic unloading system sorts and conveys the cut parts and scrap

(Three-chuck Heavy-duty Tube Laser Cutter | Senfeng USA).

The entire process is coordinated by the control system, enabling continuous unattended operation.

Working Principle:

The actual cutting principle is the same as the basic machine, with the only difference being the automation of the logistics before and after cutting. Typically, tubes in the magazine are pushed into the clamping area by the feeder; the front and rear chucks automatically align and clamp the tube

(TP Series Three Chucks Laser Tube Cutting Machine | XT LASER).

After the CNC program completes the cutting of one tube, the clamping device releases it, and the finished product is conveyed away while the tail material is automatically discarded or sent to a recycling bin. Then the next tube is automatically fed in, ensuring continuous production. This system is ideal for high-volume production lines as it significantly reduces manual loading/unloading time and greatly increases throughput.

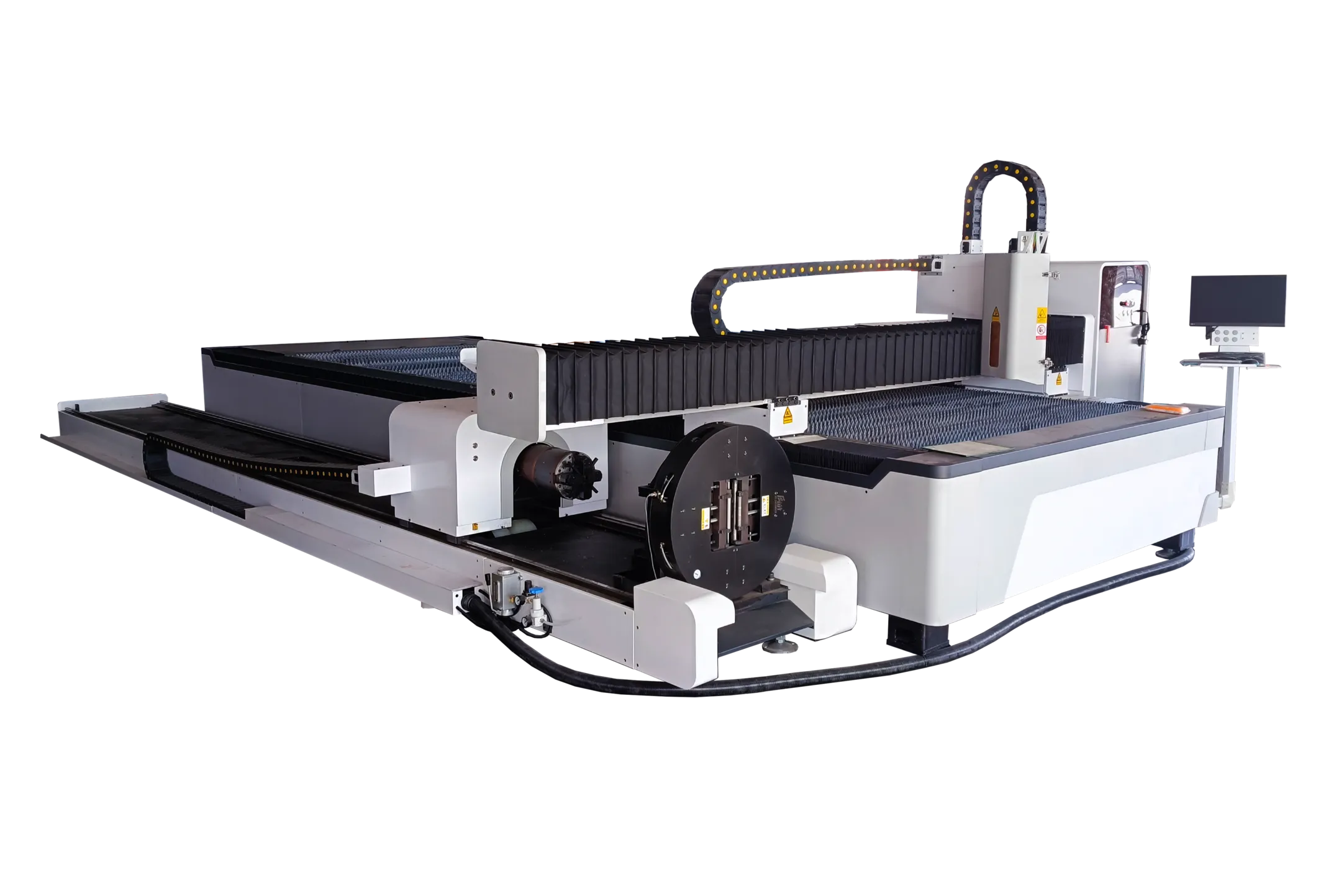

1.4 Integrated Sheet and Tube Laser Cutting Machine

Integrated sheet and tube laser cutter

An integrated sheet and tube machine is a versatile laser cutting device capable of processing both sheet metal and tubes. It is also known as a dual-purpose machine. Typically, it adds a tube clamping and rotation device to the platform structure of a sheet laser cutter so that the same machine can perform both planar and tube cutting

(Fiber Laser Sheet And Tube Integrated Cutter - CatekCNC).

Structural Features:

This type of machine features a detachable or pivotable chuck and tailstock on one side for clamping tubes. When cutting sheet metal, the tube clamping mechanism is either stationary or moved away so that it does not interfere with the sheet cutting area. Advanced integrated machines also have automatic centering and alignment functions to accommodate tubes of different diameters. Their machine bed is usually extended compared to a pure sheet machine to accommodate a certain length of tube (commonly 3m or 6m).

Working Principle:

When cutting sheet metal, the machine operates like a standard fiber laser sheet cutting machine. When switching to tube mode, the laser head moves to the tube area, the chuck clamps the tube and drives its rotation, and the laser head cuts the tube according to the program. The control system seamlessly switches between the two modes and automatically corrects the tube’s position and center alignment

(Fiber Laser Sheet And Tube Integrated Cutter - CatekCNC).

Since one machine can perform both functions, users only need to select the corresponding mode based on the cutting task, greatly saving on equipment investment and floor space

(Fiber Laser Sheet And Tube Integrated Cutter - CatekCNC).

Advantages:

Compared with purchasing separate sheet and tube cutting machines, an integrated machine saves cost and space. One device can meet both requirements and can be managed by a single operator, thereby reducing labor costs.

1.5 Specialized Non-Standard Tube Cutting Machine

Specialized Non-Standard Tube Cutting Applicable Tube Model

A specialized non-standard tube cutting machine is designed and optimized for tubes with non-standard cross-sectional shapes (i.e., specialty tubes). Such tubes include oval tubes, rectangular tubes, triangular tubes, D-shaped tubes, as well as complex profiles such as angle bars, channel sections, and I-beams. These machines feature specially designed fixtures and software to handle positioning and cutting of various cross-sectional shapes.

Structural Features:

They often adopt an adaptive clamping structure, such as replaceable/adjustable chuck jaws or chucks with a wider and specially contoured clamping surface, to securely hold non-standard tubes without damaging the surface

(Fiber Laser Tube Cutting Machine & Laser Metal Sheet Cutter - iGOLDENLASER).

Some high-end models are equipped with contour detection sensors or machine vision systems that can automatically identify the tube’s cross-sectional shape and angle, aiding in centering and clamping. The software also includes an extensive database of cross-sectional parameters to support process compensation and cutting path planning for different profiles.

Modern fiber laser tube cutting machines can process a variety of tube shapes—round, rectangular, channel, angle, oval, triangular, I-beam, etc.—with high precision and versatility.

Working Principle:

The cutting principle remains similar to that of standard machines; however, before cutting, the machine typically performs a “tube orientation” process. For example, when processing a rectangular tube, the machine ensures that its face is aligned with the laser cutting plane; for open-profile materials like channel or angle sections, fixtures hold them in a specific orientation. Specialized machines use dedicated clamping and sensor systems to quickly auto-align the tube and then cut various holes and profiles according to the set trajectory. Some advanced five-axis machines can also perform bevel cutting on the ends of H-beams or other profiles, but most fiber laser tube cutting machines primarily handle two-dimensional cross-sectional cutting.

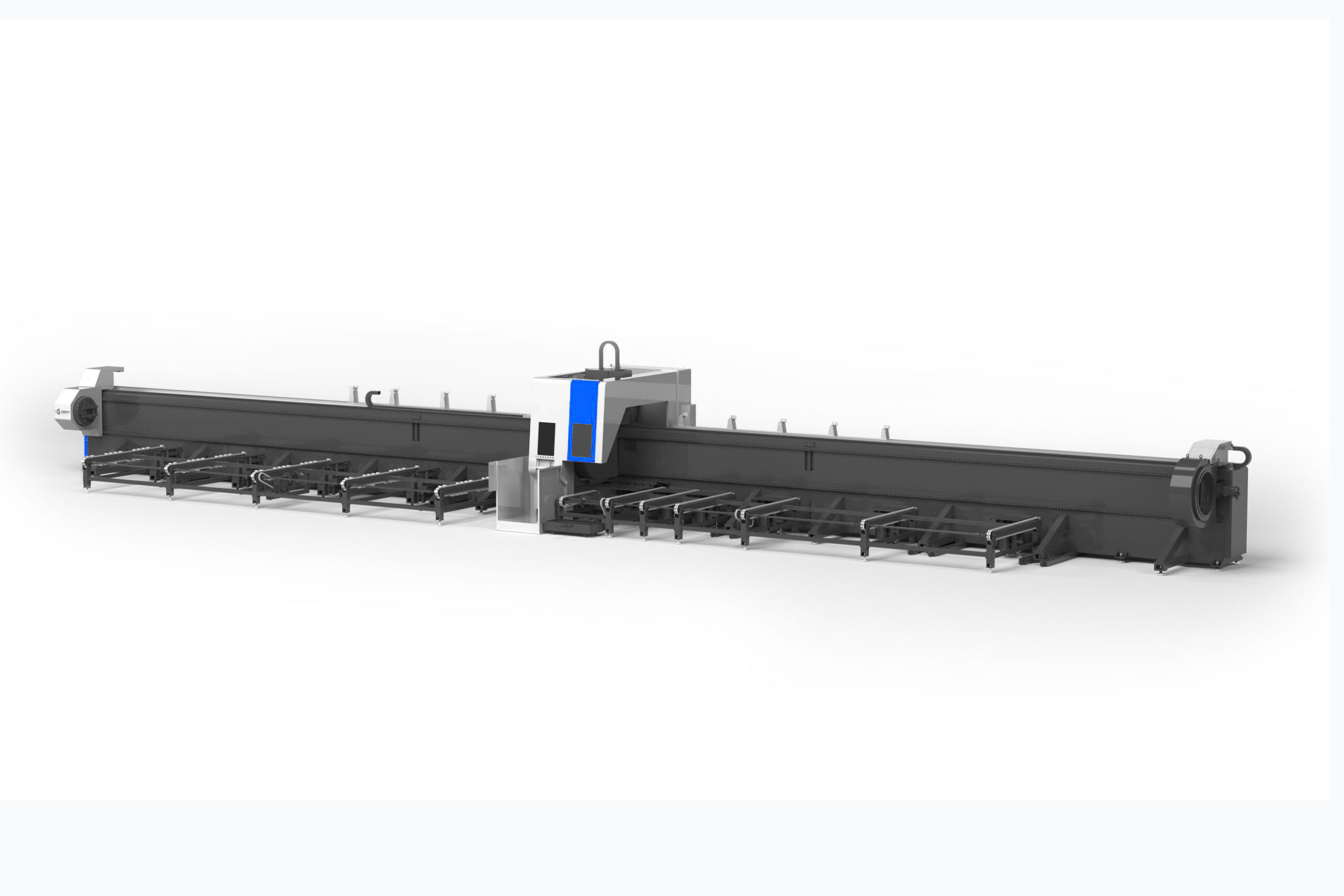

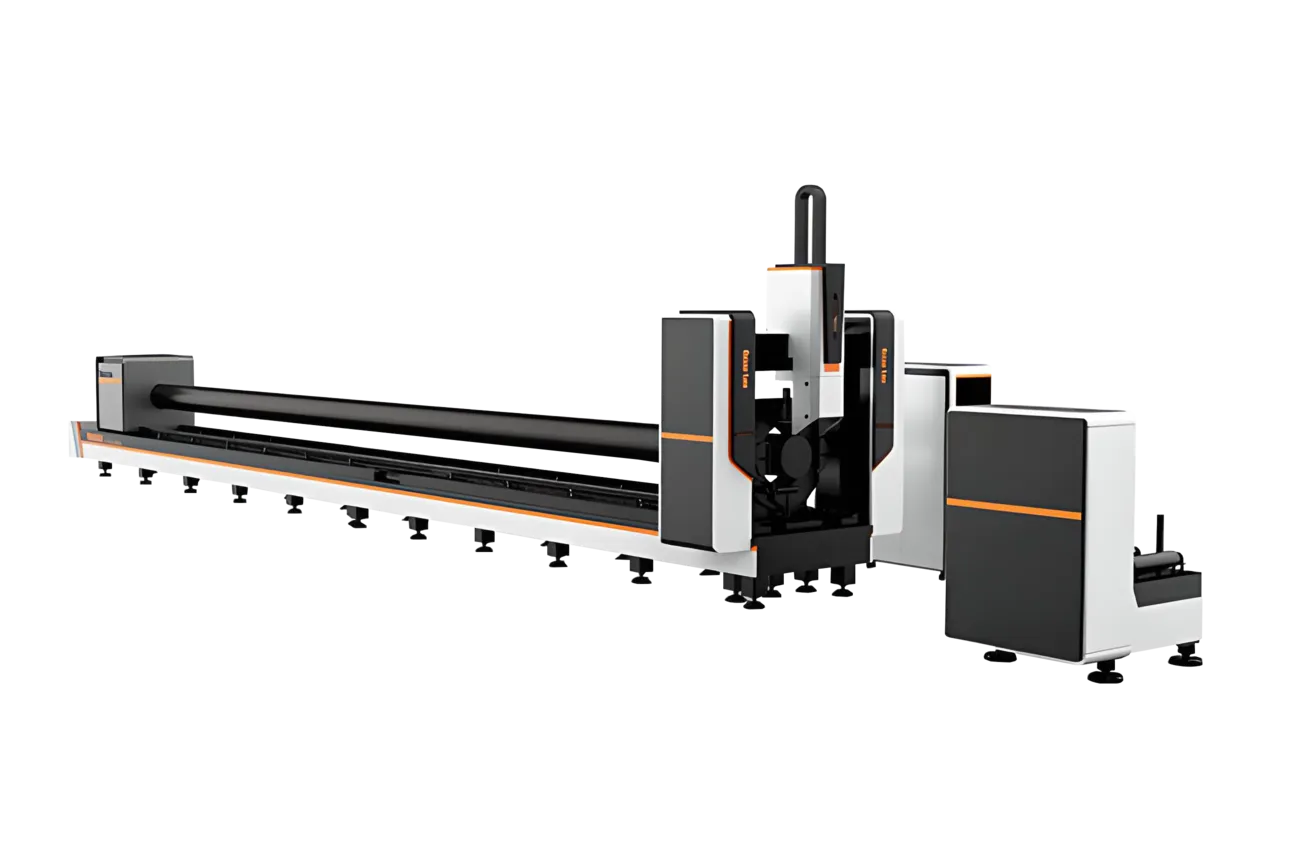

1.6 Heavy-Duty Tube Cutting Machine

Heavy-Duty Tube Cutting Machine

Heavy-duty tube cutting machines are designed for large-diameter, thick-walled tubes and profiles. They are characterized by a highly rigid machine bed, high load-bearing capacity, high-power laser sources, and often offer multi-chuck configurations.

Structural Features:

The entire machine is built on a reinforced heavy-duty bed with high-power servo drives, capable of handling tubes weighing several tons while maintaining stable motion

(Three-chuck Heavy-duty Tube Laser Cutter | Senfeng USA).

The chucks have larger diameters and clamping forces; some heavy-duty machines use three or even four chucks to support ultra-long and heavy tubes

(Heavy Duty Tube Laser Cutting Machine - Baison).

For example, a certain heavy-duty model can be equipped with four chucks to clamp giant tubes up to 500mm in diameter, ensuring stability during prolonged cutting

(Heavy Duty Tube Laser Cutting Machine - Baison).

The laser source power in heavy-duty machines usually ranges from 3000W to over 10000W, and the cutting head may offer tilt capabilities for bevel cutting of thick-walled tubes. The typical processing lengths are 6m, 9m, or even 12m, and these machines are often equipped with automatic feeding/unloading systems to handle bulky workpieces.

Working Principle:

The control method is similar to that of standard machines, but due to the high load, the acceleration and rotation speeds are relatively lower to ensure safety and smooth operation. When cutting large tubes (with diameters of several hundred millimeters), the rotational acceleration is limited to avoid excessive inertia. For thick-walled materials, a high-power laser combined with high-pressure oxygen assist is typically used for stable melting cutting; for tubes that require beveling for welding, a tilting cutting torch creates a bevel to facilitate subsequent welding. These machines are widely used in industries such as construction steel structures, pipeline manufacturing, and offshore engineering.

2. Performance Indicator Comparison of Different Tube Cutting Machine Types

Different types of fiber laser tube cutting machines have varying performance indicators regarding the size range of tubes they can process, motion speed, accuracy, applicable materials, and so on. The table below summarizes typical performance parameters for the main machine types for easy comparison:

| Machine Type | Typical Tube Diameter Range | Maximum Tube Length | Applicable Laser Power | Positioning Accuracy | Max Rotational Speed | Supported Tube Shapes | Applicable Materials | |

|---|---|---|---|---|---|---|---|---|

| Two-Chuck Machines | Approximately Φ15–220mm1 | 6m (option for 8m or more) | Typically 1500W–4000W, up to ~6000W | ±0.05mm2 | ~80–100 rpm | Round, square, rectangular, oval and other conventional profiles ([170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine](https://favolaser.com/products/170g6-two-chuck-fiber-laser-tube-cutting-machine/#:~:text=Cut%20Multi%20Types%20of%20Tubes)) | Carbon steel, stainless steel, aluminum alloys, copper alloys, etc. |

| Three-Chuck Machines | Approximately Φ20–350mm3 | 6m (option up to 12m) | Typically 1500W–6000W | ±0.05mm | ~80 rpm | Round, square, rectangular (also supports non-standard profiles) | Carbon steel, stainless steel, aluminum alloys (with enhanced thick-wall capability) | |

| Automatic Feeding Machines | Approximately Φ15–220mm (depending on the main unit) | 6m or more (with automatic magazine) | Typically 2000W–6000W | ±0.05mm | ~80–100 rpm | Round, square, etc. – many models support profile cutting | Carbon steel, stainless steel, aluminum alloys, etc. | |

| Integrated Sheet and Tube Machines | Approximately Φ20–160mm (typical) | 3m–6m (depending on the model) | Typically 1000W–3000W | ±0.05–0.1mm | ~60–80 rpm | Round, square, rectangular; limited non-standard profiles | Mainly for thin-walled materials (carbon steel, stainless steel, aluminum alloys) | |

| Specialized Non-Standard Tube Machines | Approximately Φ15–200mm (typical) | 6m (similar to two-chuck machines) | Typically 1000W–4000W | ±0.05mm | ~80 rpm | Round, rectangular, oval, angle, channel, I-beam, etc. | Carbon steel, stainless steel, aluminum alloys, etc. | |

| Heavy-Duty Machines | Approximately Φ50–800mm4 | 6m–12m | 3000W–12000W | ±0.05–0.10mm | ~30–80 rpm (decreases with larger diameter) | Round, large-diameter tubes, H-beams, channel sections, etc. | Mainly carbon steel and stainless steel (capable of processing thick-walled parts) |

1 Some standard two-chuck machines can support larger diameters (e.g., over 300mm); the above parameters are for a typical medium-power model.

2 High-performance models can achieve a positioning accuracy of around ±0.03mm, depending on the mechanical and optical systems.

3 An LT Laser three-chuck model has a clamping range of 40–620mm.

4 The Baison V52UTT heavy-duty machine with four chucks supports tube diameters from 50–500mm.

Observations from the Table:

- Processing Diameter Range: Two-chuck and integrated machines mainly cover small to medium diameter tubes (<200mm), three-chuck machines generally handle up to 240mm, while heavy-duty machines can process ultra-large diameters (up to 0.5m).

- Processing Length: Standard machines are typically configured for 6m feeding lines, with options for 8m or 12m; heavy-duty machines often use longer lengths to reduce changeover frequency.

- Laser Power: Small to medium machines generally operate around 3000W, capable of cutting carbon steel up to approximately 8–12mm thick; heavy-duty machines are equipped with high-power lasers (>6000W) to meet the demands of thick-walled tube cutting.

- Accuracy: Thanks to high-precision ball screws/linear guides and advanced controls, two-chuck/three-chuck machines commonly achieve repeatability of around 0.05mm (TP Series Three Chucks Laser Tube Cutting Machine | XT LASER). Integrated machines are slightly less accurate (around 0.1mm).

- Speed: Most machines can achieve rapid non-cutting travel speeds of 80–100 m/min, and rotational speeds in the tens to over a hundred rpm; heavy-duty machines have lower rotational speeds due to increased inertia.

- Supported Tube Shapes: Modern laser tube cutting machines generally support multiple cross-sectional shapes including round, square, rectangular, oval, as well as angle, channel, and I-beam profiles

(170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine). Some machines can clamp different shapes without changing the jaws, achieving true multi-functionality. - Compatible Materials: Common materials include carbon steel, stainless steel, aluminum alloys, copper, brass, and other conductive metals. Carbon and stainless steel cutting are the most common, while cutting aluminum and copper requires sufficient power and excellent beam control. Fiber lasers, with their short wavelengths, have an advantage in cutting highly reflective colored metals compared to CO₂ lasers, so most fiber laser tube cutting machines can handle a wide range of metals.

3. Advantages and Disadvantages of Different Tube Cutting Machine Types

Below is a comparison of the pros and cons of various machine types:

-

Two-Chuck Tube Cutting Machines:

Advantages: Simple and mature structure, relatively low cost, and easy adjustment and maintenance. Two-point clamping meets the requirements for most short to medium tube processing, offering high cutting efficiency and acceptable accuracy.

Disadvantages: When processing long or slender tubes, rigidity may be insufficient and the mid-section can vibrate. Additional supports may be required; also, a portion of the tube (tail) must be left uncut, slightly reducing material utilization. For high-frequency loading in batch production, manual loading/unloading efficiency is relatively low. -

Three-Chuck Tube Cutting Machines:

Advantages: With an additional middle support compared to the two-chuck design, these machines effectively suppress vibrations and deformation in long tubes

(Three-chuck Heavy-duty Tube Laser Cutter | Senfeng USA). They can achieve zero tailing or minimal tail waste, improving material utilization. Accuracy is also higher when processing long tubes, making them suitable for high-precision cutting.

Disadvantages: The mechanism is more complex, resulting in higher equipment and maintenance costs; an extra chuck occupies additional space and increases the machine bed length. Calibrating the coaxiality of three chucks is more cumbersome. Furthermore, with an extra clamping point, programming and synchronizing control becomes more complex, requiring a more advanced CNC system. -

Automatic Feeding Machines:

Advantages: Equipped with automatic magazines and loading/unloading mechanisms, these machines greatly improve production efficiency and automation

(Heavy Duty Tube Laser Cutting Machine - Baison). They can run unattended continuously in high-volume production, reducing labor costs and ensuring a stable production cycle.

Disadvantages: The overall automation system is expensive and typically only justified for high processing volumes. The feeder also imposes certain requirements on tube diameter and length, and adjustments may be needed when processing different specifications. Installation and layout are more complex, and initial commissioning takes longer. -

Integrated Sheet and Tube Machines:

Advantages: Multi-functional – one machine can process both sheet metal and tubes

(Fiber Laser Sheet And Tube Integrated Cutter - CatekCNC). Ideal for small factories or R&D departments with diverse product lines, these machines offer high cost-performance, lower floor space and energy consumption, and simpler operation and maintenance (only one set of personnel and processes to train).

Disadvantages: Their specialization is somewhat compromised – the tube cutting function may be less efficient or have more limited specifications compared to dedicated tube cutting machines (e.g., a more restricted tube diameter range, or limited clamping length due to the sheet cutting area). Frequent switching between sheet and tube modes can lead to downtime. For operations focused mainly on tube processing, integrated machines may be less efficient than dedicated machines. -

Specialized Non-Standard Tube Machines:

Advantages: Customized for special-profile tubes, these machines feature dedicated clamping and control schemes to process non-standard profiles more efficiently. For profiles that are prone to deformation or difficult to align (such as angle or channel sections), specialized equipment can automatically align and adjust clamping force to ensure cutting accuracy and consistency

(Fiber Laser Tube Cutting Machine & Laser Metal Sheet Cutter - iGOLDENLASER). They also include an extensive profile library in the software to reduce manual adjustments.

Disadvantages: These machines are relatively niche and tend to be more expensive. If the range of non-standard tubes processed is limited, the cost-performance may not justify a dedicated machine. Also, since they are often based on modifications of a standard two- or three-chuck design, their versatility may be inferior when processing tubes beyond the designed range, necessitating additional custom fixtures. -

Heavy-Duty Machines:

Advantages: Featuring high power and high rigidity, they can handle large-diameter and thick-walled tubes that standard machines cannot

(Heavy Duty Tube Laser Cutting Machine - Baison). Their robust structure ensures stable performance over long periods, and the dimensional accuracy and perpendicularity of the cut edges are outstanding in large workpieces. Many heavy-duty machines also support bevel cutting for tube ends, which enhances subsequent assembly efficiency. They provide new solutions for steel structure applications.

Disadvantages: The purchase and operating costs are extremely high. The machines are large and require significant floor space and construction work. Cutting thick-walled tubes consumes large amounts of assist gas and electricity. For most manufacturers, heavy-duty machines are only justified if processing ultra-large tubes is a core business; otherwise, they may lead to low utilization rates. Additionally, processing small parts on a heavy-duty machine may be inefficient due to longer clamping adjustment times and overkill in capability.

4. Analysis of Application Scenarios and Machine Suitability in Different Industries

Fiber laser tube cutting machines are widely used in many manufacturing sectors. The typical requirements vary between industries, which influences the choice of machine

(China CNC Three chuck Fiber Laser Tube Cutting Machine Manufacturers).

4.1 Automotive Manufacturing

The automotive industry makes extensive use of tubular components (e.g., exhaust pipes, chassis reinforcement, seat frames, bumpers, rollover structures). These parts require high cutting accuracy, consistency, and often feature complex non-standard holes or interconnecting profiles.

Suitable Machine Types:

Automotive production, which is usually mass-produced on assembly lines, is best served by two-chuck or three-chuck laser tube cutting machines with automatic feeding. In particular, three-chuck machines—with their high precision and minimal tail waste—enhance material utilization and ensure uniform length accuracy, making them ideal for critical automotive components

(China CNC Three chuck Fiber Laser Tube Cutting Machine Manufacturers). Large automotive plants often deploy several automated tube cutting machines integrated with robotic arms for unattended production to meet high throughput. For heavy-duty tubes used in chassis components (such as truck frame beams), heavy-duty tube cutting machines are recommended for processing thick-walled, high-strength steel. Automotive applications also demand extremely high equipment reliability; therefore, high-end machines with automatic diagnostics and stable control systems (such as those featuring bus control and advanced programming software) are preferred. In summary, the automotive industry favors high-speed, high-precision, and highly automated tube cutting equipment to ensure consistency and efficiency in mass production.

4.2 Furniture Manufacturing

Metal furniture (e.g., office desks and chairs, metal beds, and cabinets) commonly uses metal tubes as the frame structure. These products typically use small to medium diameter carbon steel or stainless steel tubes with thin walls (predominantly 1–3mm). Although there is a wide variety of parts, the production volume for each specification is also high, emphasizing high efficiency and low-cost processing.

Suitable Machine Types:

Furniture manufacturers usually opt for two-chuck laser tube cutting machines with automatic feeding. Two-chuck machines are adequate for the typical dimensions of furniture tube components, and the automatic feeding function significantly increases throughput by reducing manual handling. For example, chair leg tubes and table frame tubes can be cut in batches automatically and then proceed to welding. For decorative tubes that require patterned or perforated cuts, the high-speed and high-quality cutting capability of fiber lasers ensures smooth, burr-free edges, minimizing secondary finishing. Since very high power is not required (most applications can be met with lasers below 3kW), an economical two-chuck machine is sufficient. Moreover, if the product line includes both tube and sheet components (e.g., cabinet panels), an integrated sheet and tube machine can be considered to handle both materials with a single device, thereby reducing capital investment

(Fiber Laser Sheet And Tube Integrated Cutter - CatekCNC).

4.3 Fitness Equipment Industry

Fitness equipment such as gym strength training machines and outdoor exercise installations typically use steel tubes (round, square, or oval tubes) as primary structural components. These tubes are usually of medium diameter (commonly 25–100mm) but often have thicker walls (3–5mm or more for strength), and are mostly made of carbon steel. Many components have complex shapes requiring laser cutting of mounting holes or connecting slots.

Suitable Machine Types:

For fitness equipment tube cutting, the requirements are for high power and robust thick-wall cutting ability; hence, machines with higher power (above 3000W) are typically used. For tubes with moderate diameters, either two-chuck or three-chuck machines can be employed; when the tube length is long or minimal tail waste is desired, three-chuck machines are preferable. Given the high production volumes and variety of models in this industry, the introduction of automatic feeding is also valuable to enhance efficiency and reduce labor costs. For exceptionally thick-walled tubes (>5mm) or for large-diameter special equipment (such as large training frames), heavy-duty tube cutting machines may be considered to perform both cutting and beveling in one pass, thus avoiding secondary processing with plasma or mechanical cutting. Overall, the fitness equipment industry requires medium to high power, high stability tube cutting machines with a degree of automation to ensure high-quality cutting of thick-walled steel tubes.

4.4 Medical Device Industry

In the medical device sector, metal tubes are mainly used in two categories: first, in the frames of medical furniture (e.g., hospital beds, stretchers, wheelchairs) which are mostly made of stainless steel or aluminum tubes with diameters between 20–50mm; second, in small-diameter tube components for certain medical instruments (e.g., surgical tool shafts, small support tubes). The former has similar requirements to furniture manufacturing, while the latter demands extremely high precision and miniaturization.

Suitable Machine Types:

For medical furniture products, a two-chuck laser tube cutting machine is typically sufficient. Fiber laser cutting of thin-walled stainless steel tubes ensures smooth cut edges without damaging the oxide layer, maintaining both aesthetics and corrosion resistance

(170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine).

These companies generally have moderate production volumes and product varieties; they may opt for automatic feeding to improve efficiency or choose an integrated machine to cut both sheet and tube components. For very small tube components (e.g., stainless steel tubes only a few millimeters in diameter), a dedicated precision laser tube cutting machine may be required—often using pulsed or ultrashort pulse lasers rather than conventional fiber lasers. In the medical device industry, cut quality and precision are paramount, so the machine must produce burr-free cuts and control residual particles strictly. In summary, most medical device manufacturers are best served by small to medium high-precision two-chuck machines, with custom solutions for exceptionally precise components.

4.5 Architectural Decoration Industry

Architectural decoration covers a wide range of applications such as curtain walls, metal structural decorations, stair handrails, guardrails, and lighting frames. The tube materials used range from small stainless steel decorative tubes to large structural steel tubes. This industry is characterized by diverse specifications: it involves both artistically shaped small tubes and large support tubes; production modes can be both mass-produced and customized.

Suitable Machine Types:

For the architectural steel structure sector (e.g., space trusses, large curtain wall brackets), which uses large-diameter, thick-walled steel tubes, heavy-duty laser tube cutting machines are necessary. These machines can cut H-beams or round tubes with dovetail-like connectors, improving assembly efficiency for large components

(China CNC Three chuck Fiber Laser Tube Cutting Machine Manufacturers).

The bevel cutting function of heavy-duty machines is also used for preparing weld edges in steel structures. Some specialized steel companies even deploy robotic 3D laser cutting systems for complex spatial angles, but for general straight tube cutting, heavy-duty fiber laser machines are efficient and cost-effective.

On the other hand, for metal decorative products (such as stainless steel screens, sculpture frames, stair handrails), the tube dimensions are generally small to medium, but they often require patterned cuts or the joining of non-standard tubes. Such businesses are usually order-driven and work in small batches; hence, a general-purpose two-chuck or three-chuck laser tube cutting machine is recommended. If sheet components are also involved, an integrated machine can be attractive, as one device can handle both types of materials. Architectural decoration companies generally do not demand extreme cutting accuracy, but they require high processing flexibility so that the equipment can quickly switch between different material specifications and designs. The flexible programming and broad compatibility of fiber laser tube cutting machines are significant advantages here—for example, switching from round tube railings to square tube curtain wall brackets without changing equipment, simply by loading the appropriate program.

Therefore, the architectural decoration industry typically deploys medium-power (around 3000W) universal laser tube cutting machines, with the addition of automatic loading/unloading depending on production volume. For large-scale steel structures, heavy-duty machines are separately acquired to cover the full range of tube sizes.

4.6 Hardware Processing Industry

The hardware processing industry covers a wide range of metal fabrication services characterized by diverse customer requirements, varying raw material specifications, and a need for flexible and timely processing. For hardware manufacturers specializing in tube cutting, they face orders for tubes of various materials, profiles, and lengths.

Suitable Machine Types:

A two-chuck laser tube cutting machine is ideal due to its simple structure and fast changeover, which is well suited for processing small batches of various types

(170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine).

Modern two-chuck machines often feature intelligent chucks that can clamp tubes in the range of Φ20–200mm without needing to change jaws, and can automatically adjust the clamping force based on wall thickness to avoid damaging thin-walled tubes. This is particularly important for hardware processing, where frequent changes in tube types occur, thereby greatly improving work efficiency. If the production includes both sheet and tube parts, an integrated sheet and tube machine is also attractive, as one machine can handle both orders. For occasional orders involving large-diameter tubes beyond the capability of standard machines, companies may collaborate with partners that have heavy-duty equipment or invest in a heavy-duty machine. However, most hardware processing factories deal with small to medium components; thus, a general-purpose two-chuck/three-chuck machine covers most needs. In summary, the hardware processing industry values the versatility and stability of the equipment, as well as the ease of programming and operation to quickly respond to custom orders.

5. Selection Recommendations Based on Different User Needs

Depending on the production characteristics and business focus of an enterprise, the optimal machine configuration will vary. Below are selection recommendations for several typical scenarios:

-

High-Efficiency Mass Production:

If your main requirement is high-volume, assembly-line production with the lowest per-unit cost and highest output, it is recommended to choose a laser tube cutting machine with high power and high automation. For example, a two-chuck or three-chuck machine equipped with automatic loading/unloading can run unattended for long periods, greatly reducing waiting time for material handling and increasing overall production efficiency

(Heavy Duty Tube Laser Cutting Machine - Baison).

The three-chuck structure can also reduce tail waste per tube, improving material utilization. In addition, high-power lasers (e.g., above 6000W) shorten cutting time and can handle thicker tube walls without slowing the cycle. In scenarios such as automotive components and mass-produced furniture, this high-speed, automated tube cutting production line significantly enhances competitiveness. It is important to coordinate upstream and downstream processes (cutting, welding, etc.) to fully utilize the equipment capacity. -

Diverse Custom Processing:

If your business is characterized by a wide variety of products, small batch sizes, or predominantly custom orders (e.g., custom metal furniture, artistic installations, small hardware workshops), the focus should be on equipment flexibility and versatility. Priority should be given to two-chuck laser tube cutting machines or integrated sheet and tube machines. Two-chuck machines allow for rapid model changes and have software that supports various cross-sectional cutting patterns, meeting constantly changing order requirements

(170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine).

When choosing, pay attention to the clamping range and select models that can clamp different diameters/shapes without changing fixtures, thereby reducing adjustment time. If your business also involves sheet cutting or you have limited space and budget, an integrated machine is an all-in-one solution that can process both tubes and sheets

(Fiber Laser Sheet And Tube Integrated Cutter - CatekCNC).

Although the integrated machine may have limitations for extreme specifications, it covers most common requirements for custom processing. Additionally, in a multi-product environment, the ease of use and software functionality are crucial—the system should feature a user-friendly programming interface with an extensive cutting process library and nesting capabilities to shorten the setup time for new products and enable truly flexible manufacturing of “small batches of diverse products.” -

Heavy-Duty Thick-Wall Tube Processing:

When dealing with ultra-large diameter or thick-walled tubes (such as in construction steel structures, pipeline manufacturing, or offshore equipment), a heavy-duty laser tube cutting machine is required. In these scenarios, the workpieces are typically tubes with diameters above 300mm and wall thicknesses over 10mm; only a heavy-duty machine with a high-power laser and a rigid machine bed can ensure complete cutting with maintained accuracy

(Heavy Duty Tube Laser Cutting Machine - Baison).

Thus, consider a machine configured with a fiber laser of 6000W or more and a structure with three or more chucks (some ultra-long models even use four chucks) to support the weight of the workpiece

(Heavy Duty Tube Laser Cutting Machine - Baison).

Heavy-duty machines usually come standard with an automatic feeder because manual handling of large tubes is extremely challenging. When selecting, pay attention to the maximum clamping diameter and weight to ensure the machine covers your workpiece specifications, and ideally choose a model with extra capacity for future larger requirements. For applications that require bevel cutting of thick-walled tubes, confirm that the machine supports a tilting cutting head option. Although heavy-duty machines are expensive, if processing ultra-large tubes is your core business, investing in high-end heavy-duty equipment will significantly boost your competitiveness in the large-scale market with superior cutting quality and speed compared to conventional saw or plasma cutting methods. Also, consider the manufacturer’s after-sales service capabilities, as heavy-duty equipment requires specialized commissioning and maintenance, and good technical support ensures long-term stable operation.

6. Overview of General Technical Knowledge for Fiber Laser Tube Cutting Machines

This section provides an overview of the basic technical principles and industry trends for fiber laser tube cutting machines, including the principles of laser cutting, CNC control systems, and the evolution of clamping and support mechanisms. This information can serve as a technical primer for internal training.

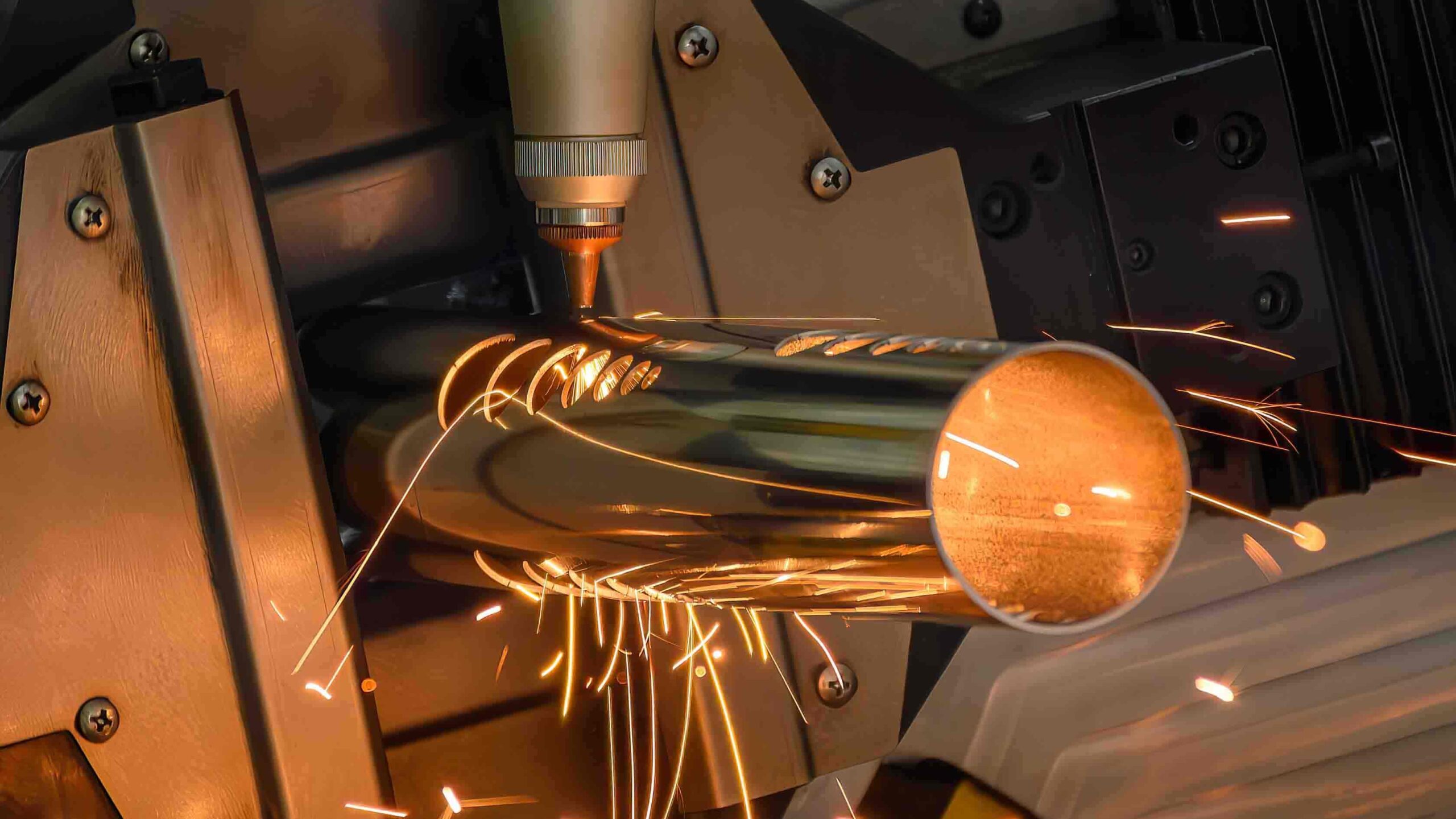

6.1 Brief Introduction to Laser Cutting Principles

Fiber laser cutting is a technology that uses a high-energy-density laser beam to thermally cut metal materials. The fiber laser produces a 1064nm wavelength beam that is transmitted through optical fibers to the cutting head. Through a focusing lens, the beam is concentrated to a very small focal point (typically 0.1–0.2mm in diameter) on the workpiece, where the power density can reach 10^6–10^8 W/cm². The irradiated material rapidly heats up to its melting or boiling point and undergoes melting or vaporization. Simultaneously, high-pressure assist gas (commonly oxygen, nitrogen, or air) is coaxially ejected from the cutting head to blow away the molten material

(The Importance of Assist Gases in Laser Cutting Applications - Baison).

As the laser beam moves along a predetermined trajectory, the material is continuously cut, forming a narrow kerf. For oxidizable materials such as carbon steel, oxygen is typically used to enhance the cutting efficiency through an exothermic oxidation reaction; for stainless steel and aluminum, nitrogen is used to prevent oxidation. Owing to its short wavelength and high beam quality, fiber laser cutting can achieve faster cutting speeds and a smaller heat-affected zone compared to traditional CO₂ laser cutting – in some cases, the efficiency on thin sheets or thin-walled tubes can be over 50% higher, and it is also easier to cut highly reflective materials (such as aluminum and copper)

(Fiber Laser Cutting Machine: An Authoritative Guide - Baison).

In tube cutting applications, the laser head typically irradiates the tube surface vertically for two-dimensional profile cutting; some machines with tilting cutting heads can achieve inclined cuts or bevels on the tube ends to meet subsequent welding and assembly requirements.

Advantages of laser tube cutting include:

- A narrow and neat kerf that usually requires no secondary processing before welding.

- A non-contact process that eliminates tool wear.

- High flexibility, allowing for the cutting of arbitrary shapes or patterns based on CNC programming.

It is important to note that when cutting thick-walled tubes, the molten metal on both sides of the kerf may re-solidify and adhere as slag; therefore, process parameters (such as increased gas pressure or segmented piercing) must be appropriately set to avoid this issue. Moreover, operators must observe laser safety protocols (wearing protective eyewear, isolating the cutting area, etc.) since fiber lasers have high output power and an invisible near-infrared beam.

6.2 Control Systems and Software

The high precision and complexity of fiber laser tube cutting rely heavily on advanced CNC control systems. Modern tube cutting machines typically use dedicated CNC systems developed specifically for tube processing, such as Germany’s PA8000 series or domestic systems like the Bochu (FSCUT) 5000 series

(China CNC Three chuck Fiber Laser Tube Cutting Machine Manufacturers).

These systems generally feature:

-

Multi-Axis Synchronized Control:

A typical tube cutting machine has five axes (X for feeding, Y/Z for the laser head’s vertical/horizontal movement, W for tube rotation, and an additional B-axis for focus adjustment or tilting of the cutting head). The control system must coordinate the movements of these axes so that the laser focal point follows a linear or curved trajectory through the workpiece. For three- or four-chuck machines, additional axes for clamping movement are required, placing high demands on the CNC hardware and software. Bus control—where all motion axes, the laser, and sensors are connected via a high-speed industrial bus for millisecond-level synchronization—is the current trend. -

Specialized Tube Nesting Software:

The control system is usually accompanied by CAM software that supports unfolding the tube surface to generate a 2D cutting layout and produce the corresponding CNC code. For example, if a square hole is to be cut on a round tube, the software will automatically “unfold” the square’s contour onto a flat plane, apply dimensional compensation based on the tube diameter, and generate the CNC code. Modern software can even extract the required cutting profiles from a 3D tube model and supports calculations for intersecting cuts—common in tube frame structures where tubes intersect and require a perfectly matched profile cut

(See How to Choose the Right Fiber Metal Laser Tube Cutting Machine).

These previously tedious manual calculations are now automated. In addition, the software provides a graphics library so that users can conveniently call up common hole shapes or patterns for tube surface cutting. -

Automatic Nesting and Path Optimization:

For batch cutting, the software can optimize the layout (nesting) of multiple parts along a long tube to maximize material utilization

(Three-chuck Heavy-duty Tube Laser Cutter | Senfeng USA).

For example, the software can determine the optimal way to cut several required segments from a 6m tube with minimal leftover material. It also generates the cutting sequence to reduce non-cutting travel and tube rotation, thereby increasing efficiency. -

Sensing and Automatic Adjustment:

Advanced CNC systems integrate various sensors for automatic edge detection/centering. For instance, for a rectangular tube, laser distance sensors can detect the side wall and automatically rotate the chuck until the tube is aligned, ensuring that the cutting pattern is not skewed. There is also height following: during cutting, capacitive sensors continuously monitor the distance between the laser head and the tube surface, driving dynamic Z-axis adjustments to compensate for slight tube bending or irregularities, ensuring a constant focal distance and consistent cut quality

(China CNC Three chuck Fiber Laser Tube Cutting Machine Manufacturers). -

Human-Machine Interface and Remote Monitoring:

Modern tube cutting CNC systems generally feature graphical HMI interfaces that support simulation of the cutting path and real-time progress monitoring. Many manufacturers also offer connectivity options to link the equipment with the factory MES system for production data collection, remote diagnostics, and maintenance. This enhances the intelligence and manageability of the equipment.

In short, the development of control systems has endowed fiber laser tube cutting machines with the characteristics of high speed, high precision, and high intelligence. From the early days of simple two-axis (rotation + feeding) control to today’s multi-axis interpolation and advanced programming, complex tube processing has become efficient and reliable. This is one of the key reasons why laser tube cutting technology has become so popular across various industries in recent years.

6.3 Evolution of Clamping and Support Mechanisms

The clamping and support structures in tube cutting machines directly affect processing stability and convenience. Ten years ago, early models typically used simple mechanical clamping methods—such as manual or hydraulic chucks—that required manual changing of jaw fixtures to accommodate different tube diameters. Today, there have been significant advancements in clamping and support:

-

Self-Centering Pneumatic/Electric Chucks:

Modern tube cutting machines almost universally employ pneumatic chucks (with high-end models using electric servo chucks) for one-touch clamping. These chucks are usually designed with three or four self-centering jaws that contract synchronously around the center via a crank linkage, allowing the tube to be clamped and centered almost instantaneously

(170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine).

Operation is simplified by controlling a foot pedal or button to actuate the pneumatic valve, eliminating the need for cumbersome manual tightening. Importantly, the clamping range is designed to be very wide—one set of jaws can cover diameter variations from several tens to over a hundred millimeters without frequent fixture changes

(170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine).

For example, some intelligent chucks can clamp tubes ranging from Φ20mm to Φ200mm without changing the jaws. Electric chucks, driven by servo motors, allow precise control of clamping force and jaw positions and are integrated into the CNC system. Additionally, modern chucks often include built-in sensors to verify that clamping is secure and that the workpiece does not slip, ensuring safety. -

Adjustable Clamping Force and Anti-Deformation Design:

To prevent thin-walled tubes from being deformed under clamping pressure, manufacturers have incorporated adjustable clamping force control. For instance, by adjusting the pneumatic pressure or servo torque, the optimal clamping force based on wall thickness can be set automatically

(170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine).

Some systems allow input of the tube material and wall thickness into the software, which then recommends a safe clamping force range. In addition to force control, the jaw design has been optimized to a large wrap-around curved surface to increase contact area and reduce indentations. Some high-end fixtures use special engineering plastics as jaw pads to protect plated or polished tube surfaces from damage. All these designs aim to clamp securely without damaging the workpiece

(Fiber Laser Tube Cutting Machine & Laser Metal Sheet Cutter - iGOLDENLASER). -

Multi-Chuck and Floating Support:

As mentioned earlier, the evolution from two-chuck to three-chuck (or even four-chuck) configurations is a major trend to improve cutting accuracy and material utilization. Coordinating multiple chucks requires solutions for synchronized drive and rapid exchange, and mature solutions now exist in both mechanical and control systems, making them applicable in heavy-duty and high-end machines. Additionally, to support long, slender tubes, floating support devices have been developed. These typically consist of a series of rollers or support brackets positioned under the tube, with automatic height adjustment to closely follow the tube’s underside

(China CNC Three chuck Fiber Laser Tube Cutting Machine Manufacturers).

Typical designs such as “snail rollers” can adapt to different tube diameters by moving vertically and synchronizing with the cutting head to continuously support the tube and prevent sagging. These auxiliary mechanisms significantly improve stability during long tube processing and reduce precision errors caused by vibration. -

Quick Centering and Material Changeover:

In older machines, manually pushing a new tube into position and aligning it required significant effort. Now, automatic centering and pneumatic pushing mechanisms are commonly employed. Automatic centering means that once the tube is clamped, the machine uses sensors (e.g., photoelectric or laser distance sensors) to detect the tube’s edge and automatically adjust the Y-axis to align the tube’s center with the rotation axis. Pneumatic pushers installed at the tailstock push the tube forward to contact the front chuck, ensuring unified axial positioning. These mechanisms reduce manual intervention, improve the repeatability of tube positioning, and make it easier for less experienced operators.

In summary, the evolution of clamping and support technology in fiber laser tube cutting machines has transitioned from manual to automatic and from purely rigid to intelligent systems. The direct benefits of this evolution include improvements in cutting precision and efficiency as well as enhanced ease of operation. In the future, we can expect further advancements such as even more intelligent self-adaptive fixtures (using sensors to recognize the tube and automatically adjust shape and force) and faster material changeover systems, all in conjunction with high-power lasers and advanced controls to continually push the boundaries of tube cutting technology.

The above report, through detailed explanation of the various types, performance characteristics, and advantages of fiber laser tube cutting machines—as well as an analysis of their suitability for different industrial applications—provides systematic guidance for equipment selection. In actual decision-making, technical indicators should be considered alongside manufacturer service, budget, and other factors. It is our hope that this guide helps readers, from an engineering practice perspective, to select the laser tube cutting equipment that best meets their production requirements, thereby enhancing processing capabilities and competitiveness.

References

-

Senfeng Laser USA – Three-chuck Heavy-duty Tube Laser Cutter (Product Features)

(Three-chuck Heavy-duty Tube Laser Cutter | Senfeng USA)

(Three-chuck Heavy-duty Tube Laser Cutter | Senfeng USA) -

XT Laser – TP Series Three Chucks Laser Pipe Cutting Machine (Specifications)

(TP Series Three Chucks Laser Tube Cutting Machine | XT LASER)

(TP Series Three Chucks Laser Tube Cutting Machine | XT LASER) -

Favo Laser – 170G6 Two-Chuck Fiber Laser Tube Cutting Machine (Equipment Configuration and Features)

(170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine)

(170G6-Two-Chuck Fiber Laser Tube Cutting Machine | Favo® Fiber Laser Cutting Machine) -

Baison Laser – Heavy Duty Tube Laser Cutting Machine (Models and Performance)

(Heavy Duty Tube Laser Cutting Machine - Baison) -

Dowell Laser – Advantages of Three-Chuck Fiber Laser Tube Cutting Machines (Technical Documentation)

(China CNC Three chuck Fiber Laser Tube Cutting Machine Manufacturers)

(China CNC Three chuck Fiber Laser Tube Cutting Machine Manufacturers) -

CatekCNC – 1530 Fiber Laser Sheet And Tube Integrated Cutter (Overview of Integrated Machines)

(Fiber Laser Sheet And Tube Integrated Cutter - CatekCNC) -

XT Laser – Industry Case Study: Laser Tube Cutting in the Sports Equipment Field (Application Note)

(TP Series Three Chucks Laser Tube Cutting Machine | XT LASER) -

iGolden Laser – Advantages of Tube & Plate Integrated Fiber Laser Cutters (Feature Description)

(Fiber Laser Tube Cutting Machine & Laser Metal Sheet Cutter - iGOLDENLASER) -

Bodor Laser – Frequently Asked Questions Guide (Design of Support Structures for Tube Cutting Machines)

(Laser Cutting Machine Buying Guide - hantencnc) -

Schütte Metals – What is Assist Gas in Laser Cutting (Principle of Assist Gas Function)